Geotechnical engineering safety monitoring system

A technology for safety monitoring and geotechnical engineering, applied in signal transmission systems, instruments, electrical components, etc., can solve problems such as slow response speed, lag in data utilization, and difficulty in on-site construction management, so as to improve accuracy and reduce monitoring blind spots. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in conjunction with the following examples.

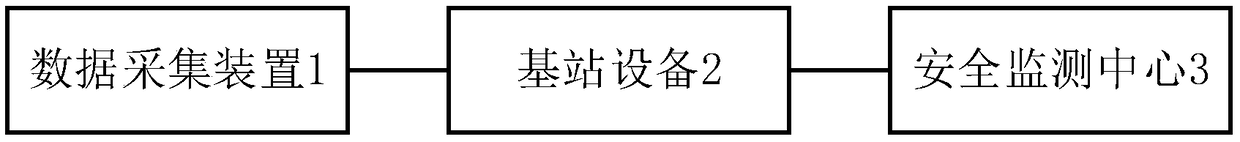

[0015] see figure 1 , a geotechnical engineering safety monitoring system, the geotechnical engineering safety monitoring system includes a data acquisition device 1, a base station device 2 and a safety monitoring center 3; the data acquisition device 1 includes a plurality of sensor nodes connected through a wireless sensor network, the sensor nodes It is used to collect geotechnical safety monitoring data and send it to the base station equipment 2. The base station equipment 2 aggregates the safety monitoring data sent by each sensor node and transmits it to the safety monitoring center 3.

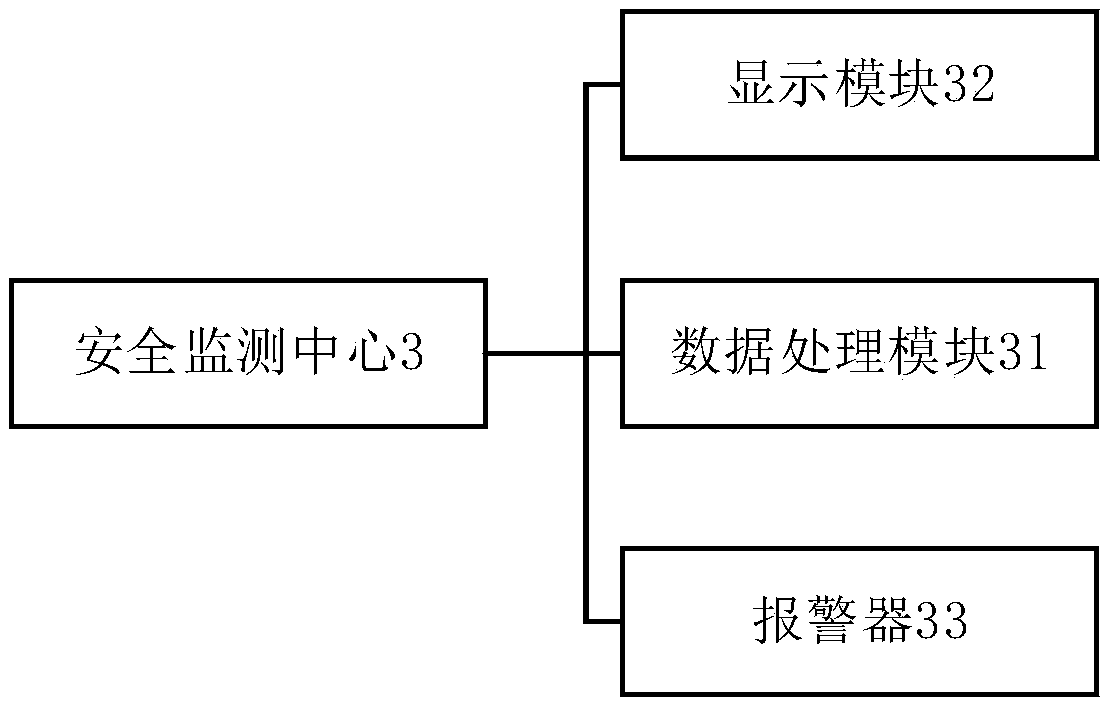

[0016] Preferably, the safety monitoring center 3 includes a data processing module 31 and a display module 32 , the data processing module 31 is used to compare the received safety monitoring data with a corresponding preset safety threshold, and output the comparison result to the display ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com