Cereal processing machine capable of automatically regulating and controlling temperature and humidity and application method thereof

A temperature and humidity, processing machine technology, applied in grain processing, non-electric variable control, control/regulation systems, etc., can solve problems such as reducing grain storage time, inconvenient for users to operate, and inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

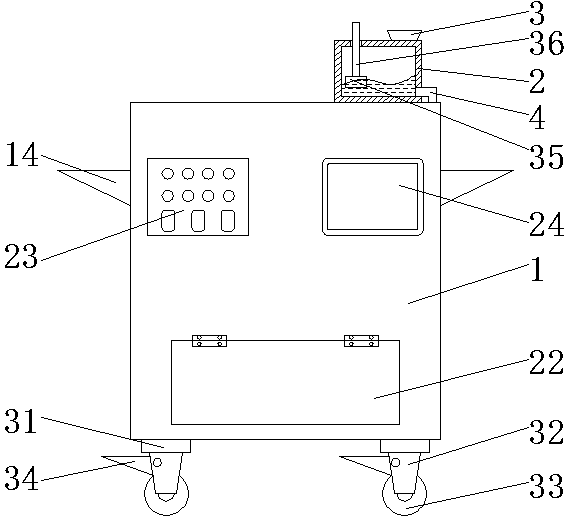

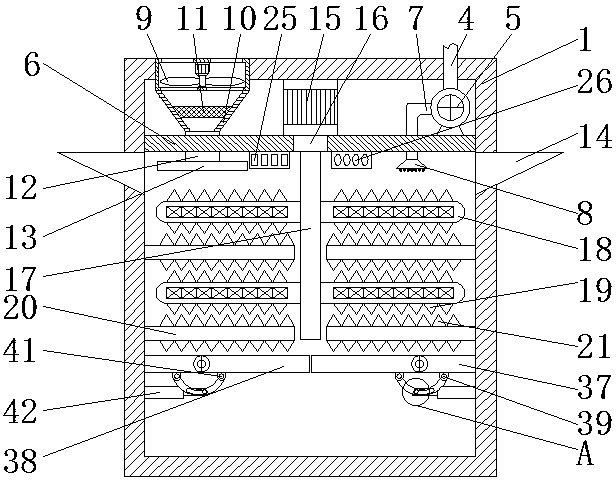

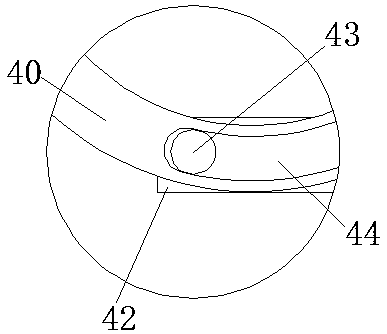

[0026] A grain processing machine with automatic temperature and humidity regulation, comprising a box body 1, a humidification box 2 is fixedly connected to the right side of the top of the box body 1, a water adding bucket 3 is connected to the right side of the top of the humidification box 2, and a water bucket 3 is connected to the right side of the humidification box 2. The bottom is connected with a first communication pipe 4, and the end of the first communication pipe 4 away from the humidification box 2 runs through the box 1 and communicates with a high-pressure pump 5. The bottom of the high-pressure pump 5 is fixedly connected with an isolation plate 6, and the two sides of the isolation plate 6 They are respectively fixedly connected to both sides of the inner cavity of the box body 1. The left side of the high-pressure pump 5 is connected with a second communication pipe 7. The end of the second communication pipe 7 away from the high-pressure pump 5 runs through ...

Embodiment 2

[0030] A grain processing machine with automatic temperature and humidity regulation, comprising a box body 1, a humidification box 2 is fixedly connected to the right side of the top of the box body 1, a water adding bucket 3 is connected to the right side of the top of the humidification box 2, and a water bucket 3 is connected to the right side of the humidification box 2. The bottom is connected with a first communication pipe 4, and the end of the first communication pipe 4 away from the humidification box 2 runs through the box 1 and communicates with a high-pressure pump 5. The bottom of the high-pressure pump 5 is fixedly connected with an isolation plate 6, and the two sides of the isolation plate 6 They are respectively fixedly connected to both sides of the inner cavity of the box body 1. The left side of the high-pressure pump 5 is connected with a second communication pipe 7. The end of the second communication pipe 7 away from the high-pressure pump 5 runs through ...

Embodiment 3

[0034] A grain processing machine with automatic temperature and humidity regulation, comprising a box body 1, a humidification box 2 is fixedly connected to the right side of the top of the box body 1, a water adding bucket 3 is connected to the right side of the top of the humidification box 2, and a water bucket 3 is connected to the right side of the humidification box 2. The bottom is connected with a first communication pipe 4, and the end of the first communication pipe 4 away from the humidification box 2 runs through the box 1 and communicates with a high-pressure pump 5. The bottom of the high-pressure pump 5 is fixedly connected with an isolation plate 6, and the two sides of the isolation plate 6 They are respectively fixedly connected to both sides of the inner cavity of the box body 1. The left side of the high-pressure pump 5 is connected with a second communication pipe 7. The end of the second communication pipe 7 away from the high-pressure pump 5 runs through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com