Automatic assembling device of mobile phone batteries

A mobile phone battery, automatic assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and high labor intensity of manual methods, and achieve the effect of reducing labor intensity and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

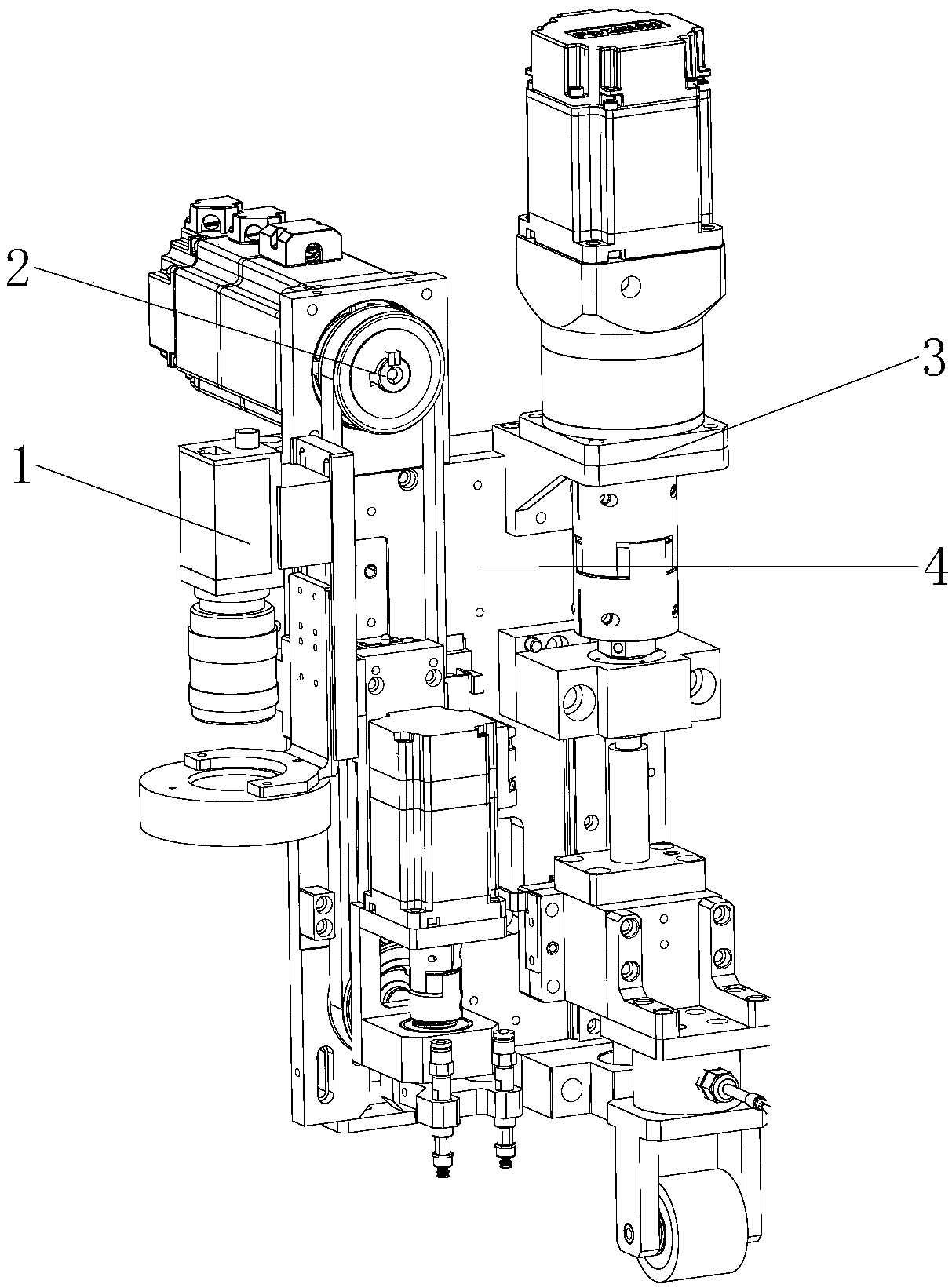

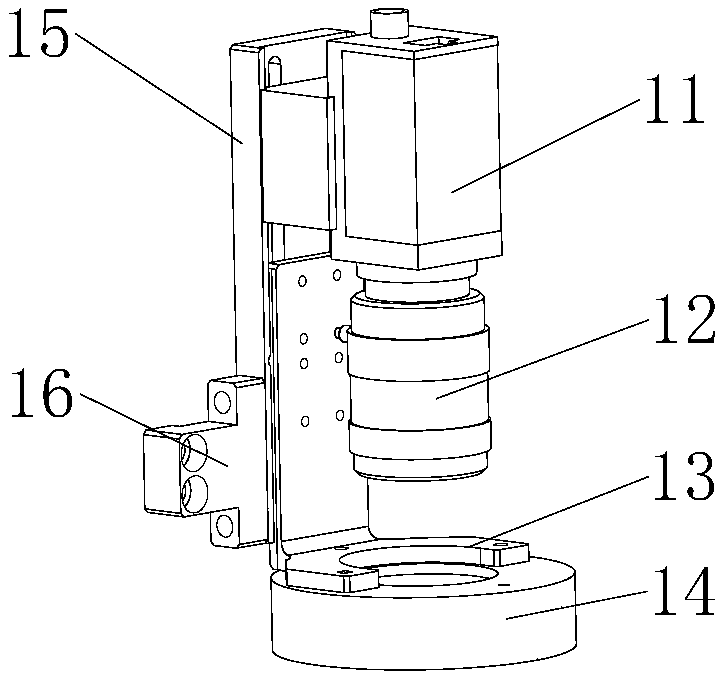

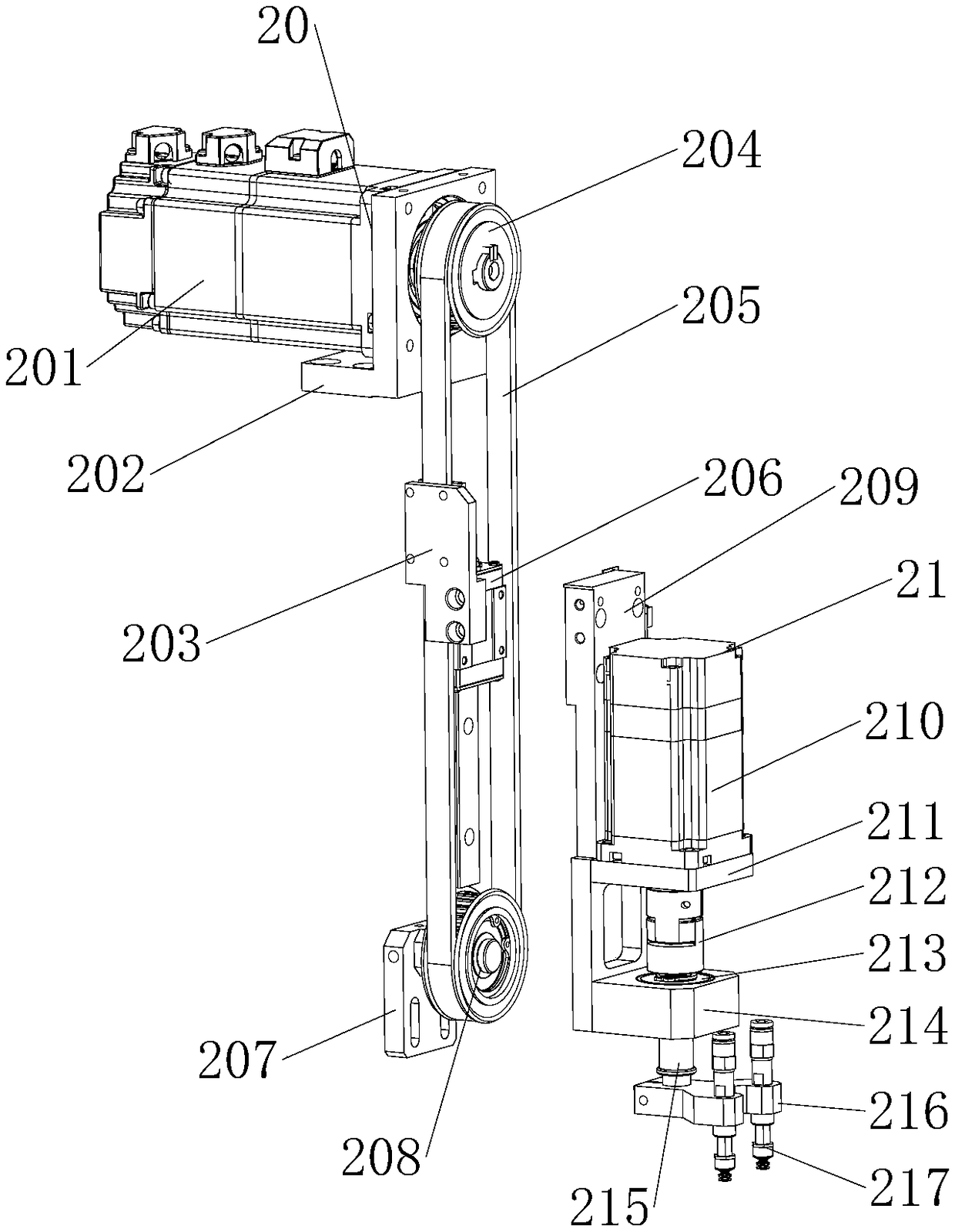

[0022] refer to Figure 1-Figure 5 , an automatic battery assembly device for mobile phones, comprising a camera assembly 1, a pick-and-place assembly 2, a rolling assembly 3, an installation connecting plate 4, an X-axis module 5 and a Y-axis module 6, and the camera assembly 1 is vertically It is installed downwards on the installation connecting plate 4, and the camera assembly 1 mainly includes a camera 11, a lens 12, a light source bracket 13, a light source 14, and a camera connecting plate 15. The camera 11 is installed on the camera connecting plate 15, and the lens 12 is installed on the camera 11. , the light source 14 is installed on the camera connection plate 15 through the light source bracket 13, the light source 14 and the axis of the camera 11 are in line, the camera assembly 1 is installed on the installation connection plate 4 through the connection block 16; the take-and-discharge assembly 2 is installed vertically downward On the installation connecting pl...

Embodiment 2

[0025] refer to figure 1 , Figure 4 and image 3 , an automatic battery assembly device for a mobile phone, which is basically the same as in Embodiment 1. Further, the camera assembly 1, the loading and unloading assembly 2, and the rolling assembly 3 are all installed on the X-axis module 5 and the Y-axis module 5 by installing the connecting plate 4. On the shaft module 6, the photographing assembly 1, the feeding and unloading assembly 2, and the rolling assembly 3 are installed in one.

[0026] A tray 7 is arranged on the machine table, and the tray 7 is located between the X-axis module 5 and the Y-axis module 6, and the tray 7 is used for loading the battery 8 of the mobile phone.

[0027] The pressure sensor 37 and the third motor 31 form a closed-loop control under the action of the control system to ensure constant pressure during rolling.

[0028] The pressure sensor 37 is a PT124G-111T pressure sensor.

[0029] At least one group of camera components 1 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com