High-efficiency press-fitting gear bushing tool

A press-fitting and gear technology, which is applied in the field of gear processing, can solve the problems of reducing product quality, bushing extrusion burrs, and reducing production and processing efficiency, so as to improve processing efficiency and avoid pressure deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

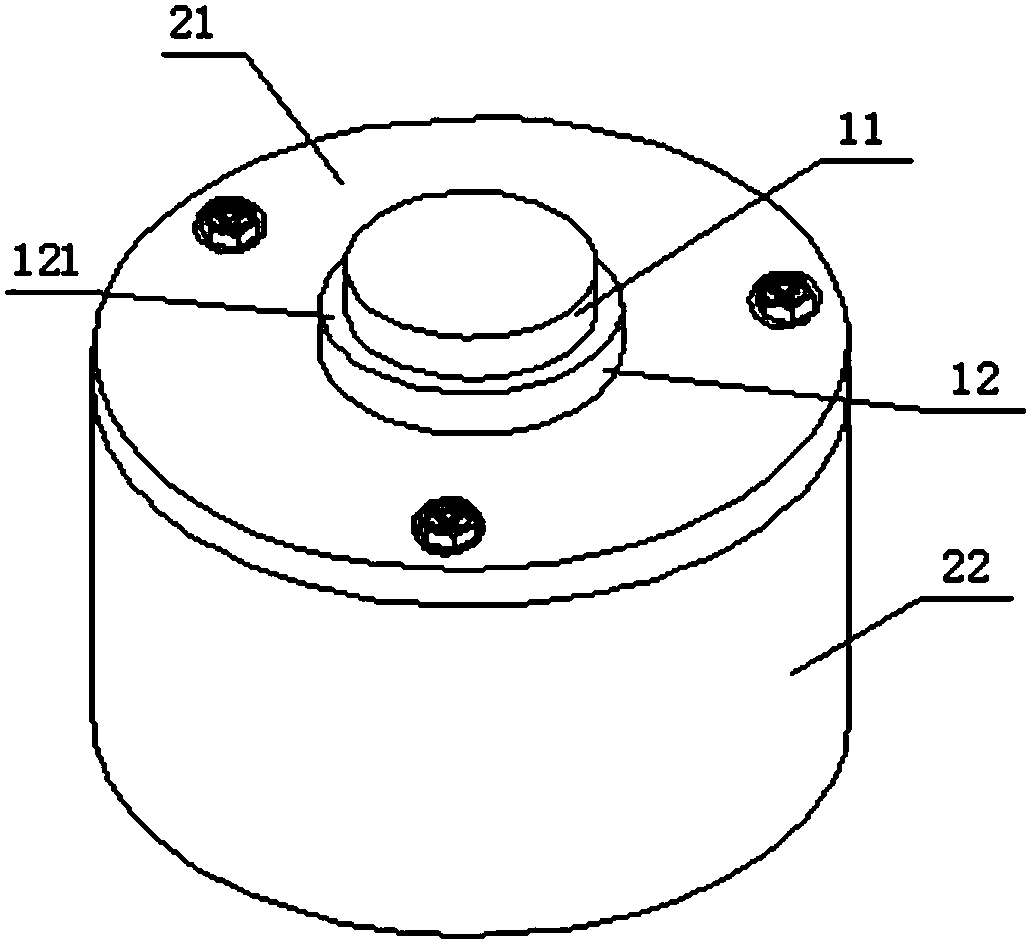

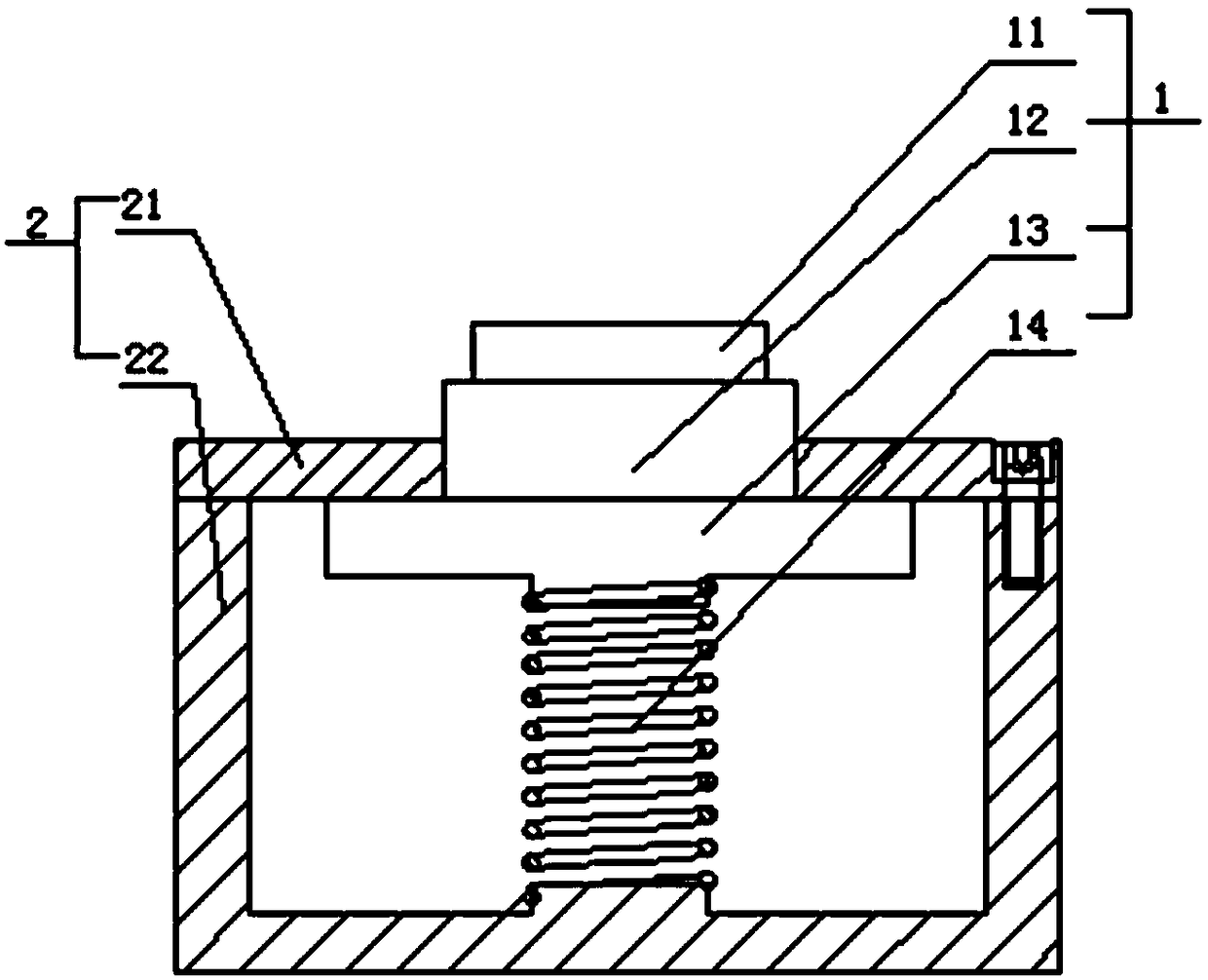

[0029] Such as Figure 1-2 As shown, a high-efficiency press-fit gear bushing tooling includes a floating boss 1 and a loading platform 2; the floating boss 1 includes a small boss 11, a large boss 12, a limit plate 13 and a floating guide mechanism; the small boss Platform 11 is a cylindrical structure, and the lower end of small boss 11 extends downwards to form a large cylindrical boss 12. The diameter of big boss 12 is greater than the diameter of small boss 11. Meanwhile, small boss 11 and big boss The intersection of the platform 12 forms an annular step surface 121; the lower end of the large boss 12 is fixed with a limit plate 13, and a floating member 14 is provided at the lower end of the limit plate 13; the loading platform 2 includes a flat plate 21 and a base 22. The flat plate 21 is detachably installed on the upper end of the base 22, and a cavity is provided in the base 22;

[0030] There is a circular through hole in the center of the plate 21, the large boss...

Embodiment 2

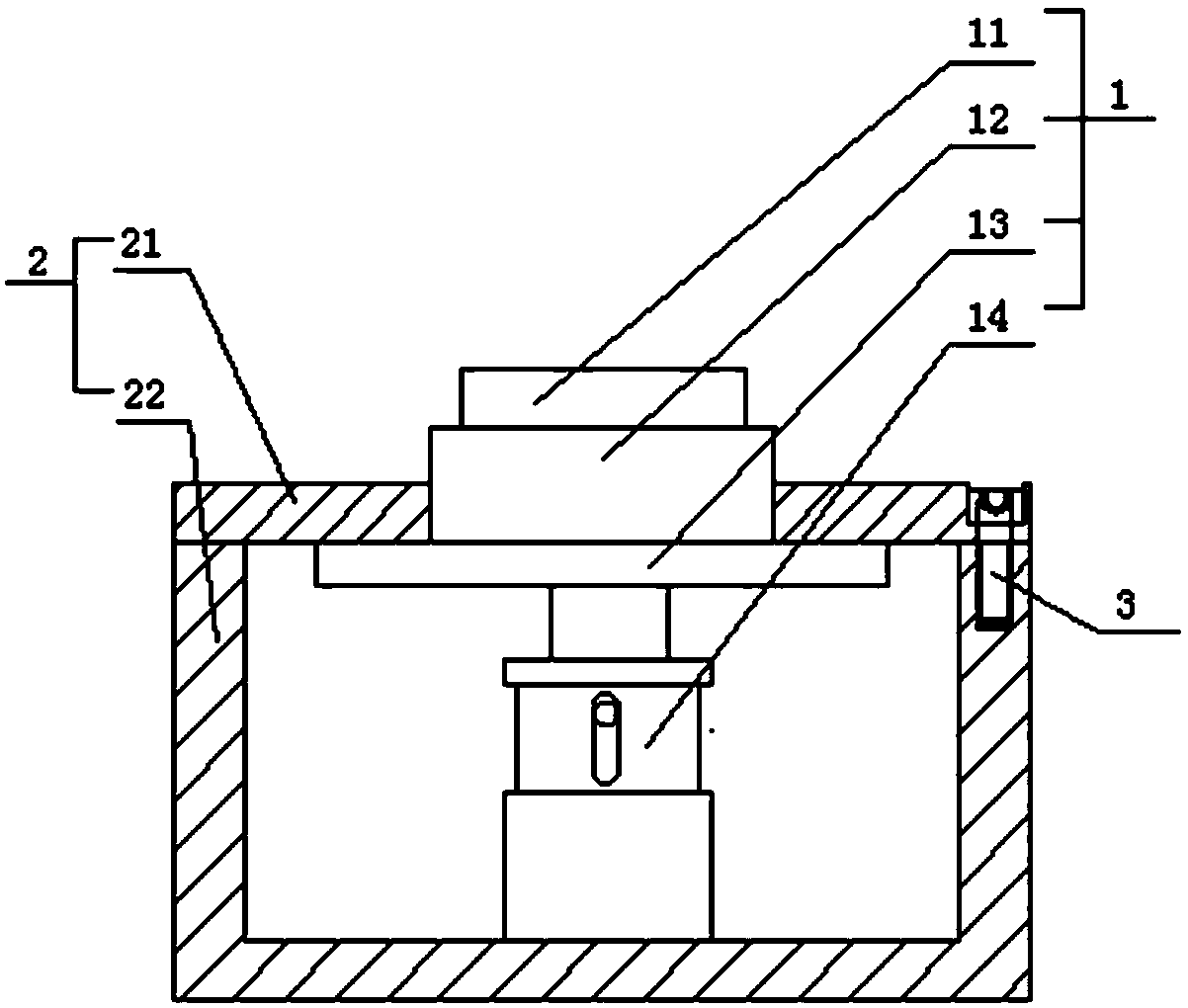

[0034] Such as figure 1 and Figure 3-5 As shown, a high-efficiency press-fit gear bushing tooling includes a floating boss 1 and a loading platform 2; the floating boss 1 includes a small boss 11, a large boss 12, a limit plate 13 and a floating guide mechanism; the small boss Platform 11 is a cylindrical structure, and the lower end of small boss 11 extends downwards to form a large cylindrical boss 12. The diameter of big boss 12 is greater than the diameter of small boss 11. Meanwhile, small boss 11 and big boss The intersection of the platform 12 forms an annular step surface 121; the lower end of the large boss 12 is fixed with a limit plate 13, and a floating member 14 is provided at the lower end of the limit plate 13; the loading platform 2 includes a flat plate 21 and a base 22. The flat plate 21 is detachably installed on the upper end of the base 22, and a cavity is provided in the base 22;

[0035] There is a circular through hole in the center of the plate 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com