Underground coal slime treatment device and treatment process thereof

A treatment device and coal slime technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve problems such as coal slime full of lanes, and achieve the effect of less equipment, high reliability and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

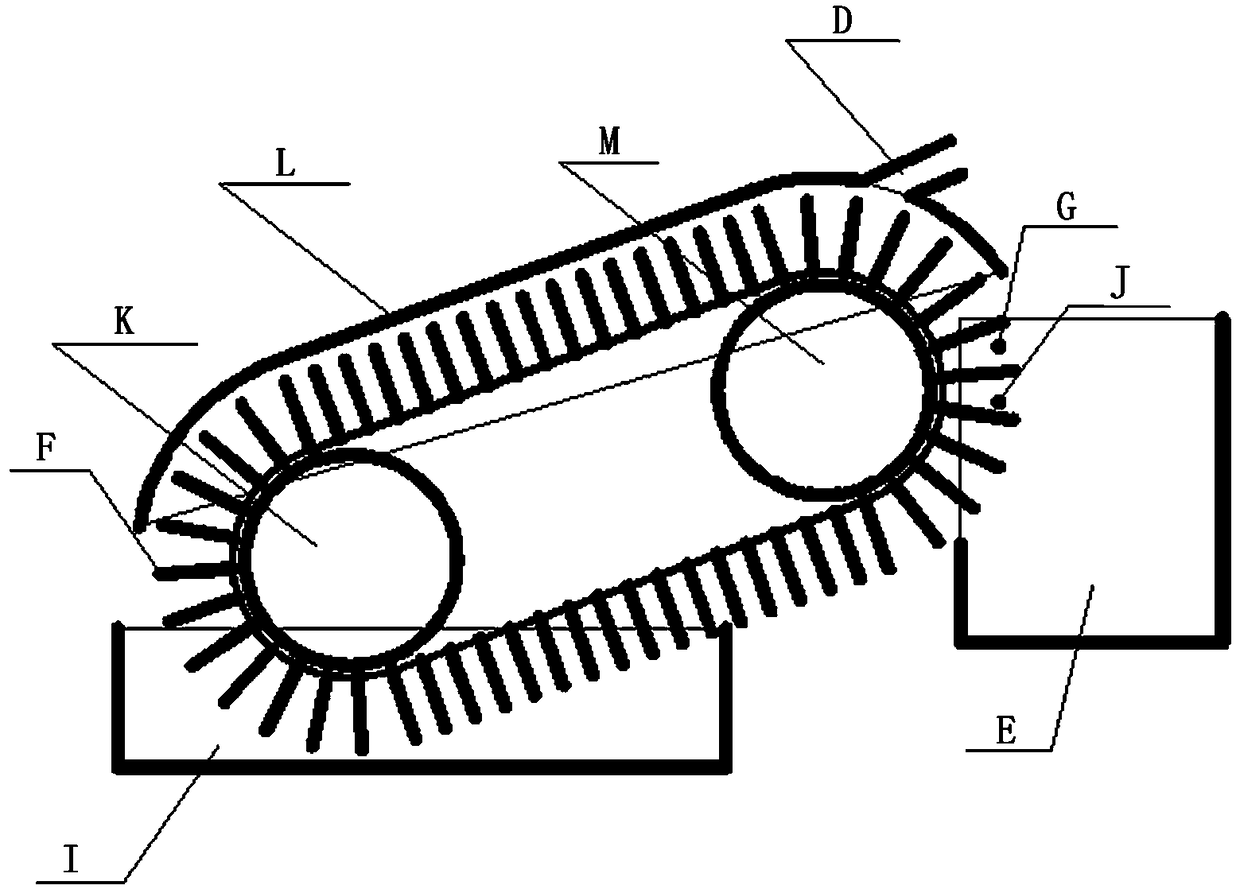

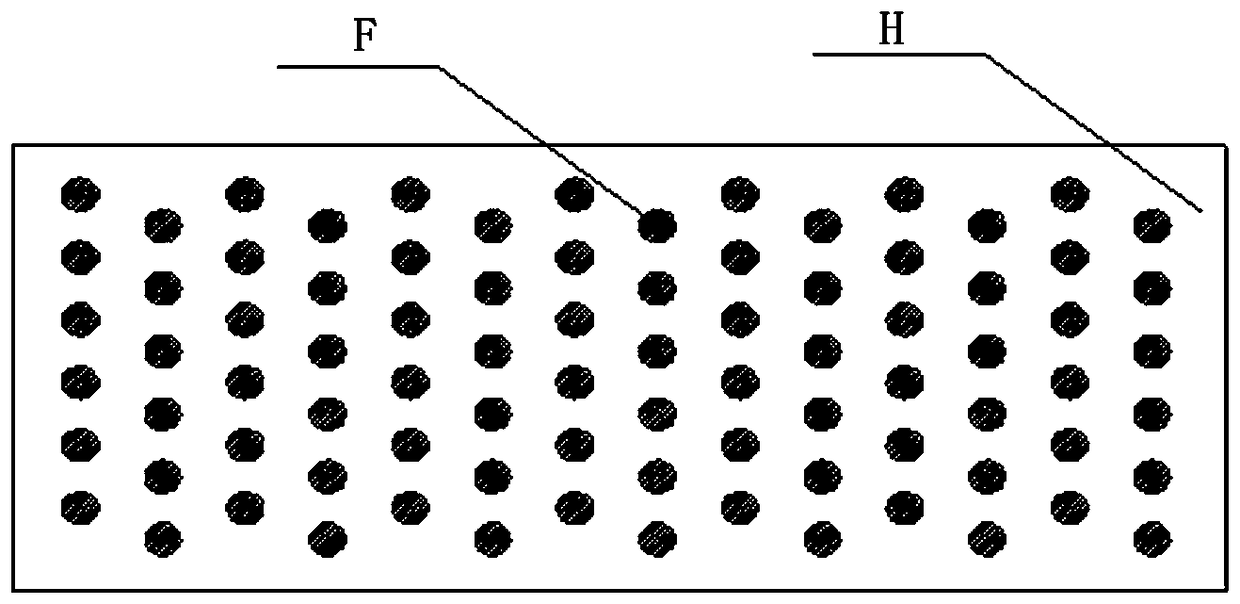

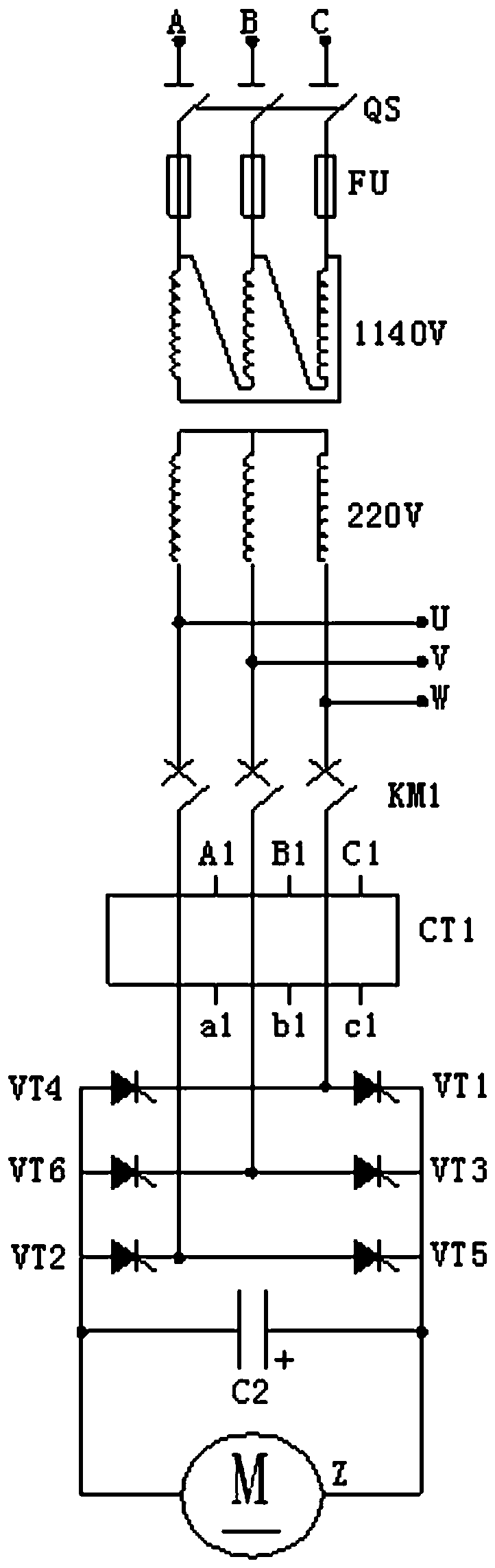

[0014] Such as figure 1 The underground coal slime treatment device shown includes a speed regulating circuit, a speed controller N, a speed-controllable driving shaft M, a driven shaft K, and the two shafts are connected by a rubber belt H with a rubber rod F The other auxiliary equipment includes slime tank I, cover plate L, air inlet D, resistance rod G, resistance rod J, and collection box E. The speed controller N is used to adjust the rotation speed of the active shaft M and start and stop.

[0015] The driven shaft K and the driving shaft M are connected by a rubber belt H to form a slime conveying mechanism. The rubber belt H is arranged obliquely and the driving shaft M is located obliquely above; the cover plate L is parallel and spaced above the rubber belt H, and the top of the cover plate L It is provided with an air inlet D penetrating the rubber rod F. The slime tank I is located obliquely below the rubber belt H, the collection box E is butted diagonally above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com