Method for preparing high-activity titanium boride ceramic powder through low-temperature microwave carbon thermal reduction

A ceramic powder, high activity technology, used in boron/boride, metal boride, chemical industry and other directions, can solve the problems of polluted environment, poor product activity and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

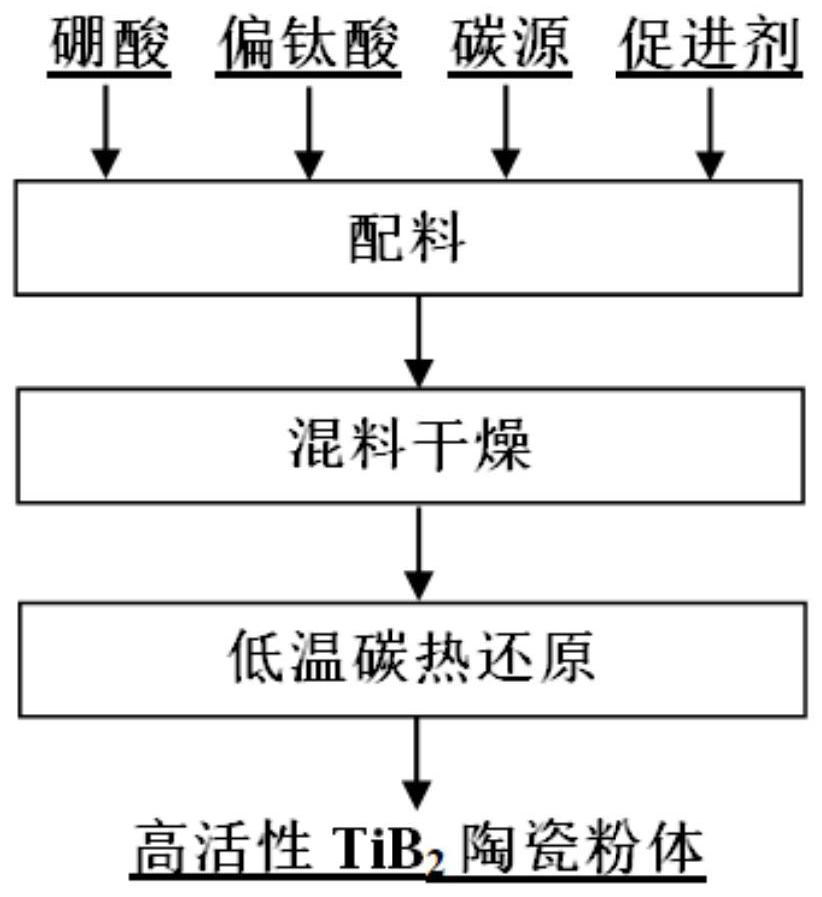

Method used

Image

Examples

Embodiment 1

[0037] Take 36g of boric acid with a purity of 99.2% and a particle size range of 50 to 80 μm, 24 g of metatitanic acid with a purity of 99.4%, and a particle size range of 10 to 20 μm, 37 g of sucrose, and 3.88 g of Na 2 O for batching, placed in a kneader with a stirring speed of 20r / min, a heating rate of 10°C / min, and a temperature of 100°C for 2.4 hours. React in a microwave atmosphere furnace at 1300°C for 40 minutes to obtain highly active TiB with a purity of 99.2% and an average particle size of 1.8 μm 2 Ceramic powder.

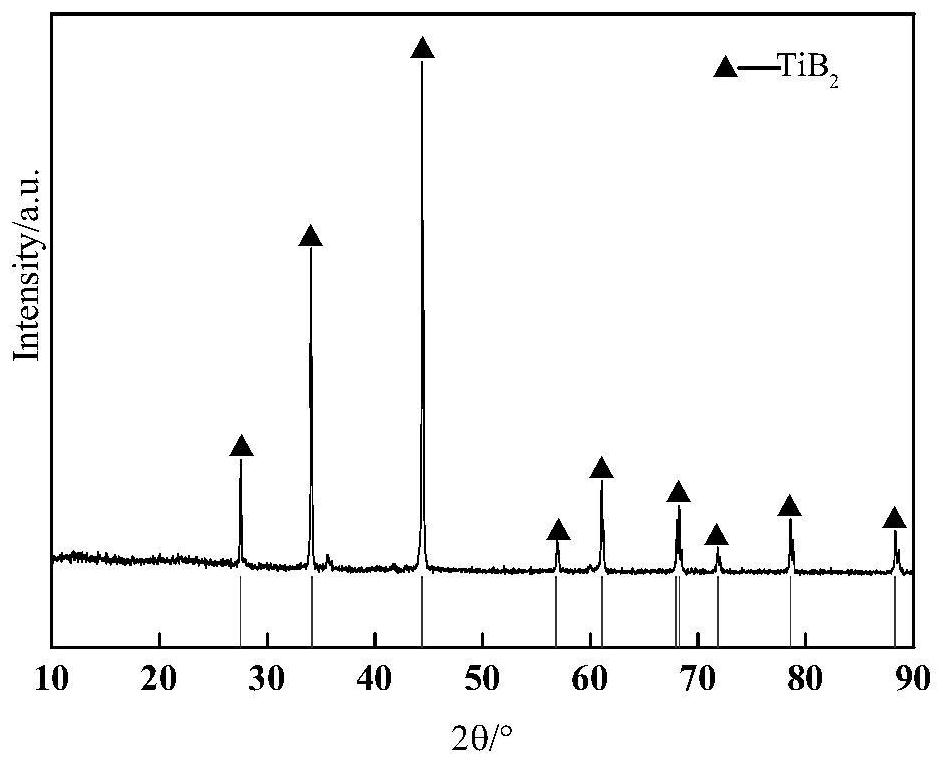

[0038] figure 2 Prepare TiB for the present invention 2 The XRD pattern of the ceramic powder shows that only TiB appears 2 Sharp diffraction peaks without other miscellaneous peaks (such as TiC, Ti 2 o 3 etc.), indicating that the TiB prepared by the present invention 2 The purity of the ceramic powder is high, which can meet the requirements of high-purity raw materials for subsequent sintering.

Embodiment 2

[0040] Take 33g of boric acid with a purity of 99.5% and a particle size range of 240 to 300 μm, 24 g of metatitanic acid with a purity of 99.2%, and a particle size range of 20 to 30 μm, 38 g of dextrin, and 8 g of Na 2 CO 3 For batching, place the kneader with a stirring speed of 100r / min, a heating rate of 20°C / min, and a temperature of 300°C for 0.3h, then place the dried raw materials in a kneader with a heating rate of 100°C / min and a temperature of React in a microwave atmosphere furnace at 1550°C for 10 minutes to obtain highly active TiB with a purity of 99.5% and an average particle size of 1.6 μm 2 Ceramic powder.

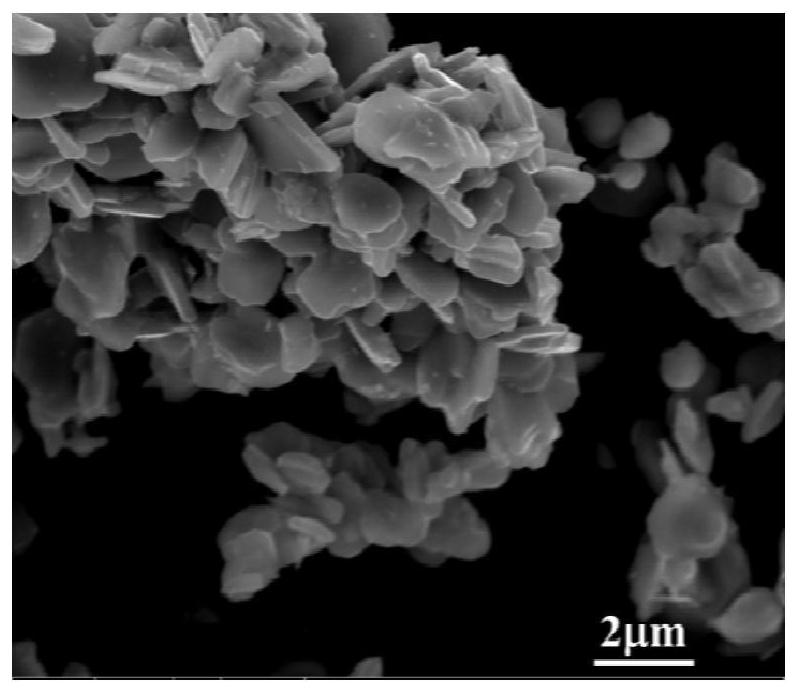

[0041] image 3 Gained TiB for the present invention 2 Microscopic morphology of ceramic powder. It can be seen from the figure that the particle size of the powder is relatively uniform, the grain size is small (2 Ceramic powder has high sintering activity.

Embodiment 3

[0043] Take 39g of boric acid with a purity of 99% and a particle size range of 100-160 μm, 24 g of metatitanic acid with a purity of 99.6% and a particle size range of 10-15 μm, 22 g of citric acid + 22 g of dextrin, 6.5 g K 2 CO 3 For batching, place the kneader with a stirring speed of 80r / min, a heating rate of 15°C / min, and a temperature of 200°C for 1.2h, then place the dried raw materials in a kneader with a heating rate of 60°C / min and a temperature of React in a microwave atmosphere furnace at 1400°C for 30 minutes to obtain highly active TiB with a purity of 99.3% and an average particle size of 1.4 μm 2 Ceramic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com