Cylindrical roller bearing retainer and processing method

A cylindrical roller bearing and processing method technology, applied in the field of bearing processing, can solve problems such as fracture and pocket wear, and achieve the effects of avoiding stress concentration, improving impact resistance, and ensuring use reliability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

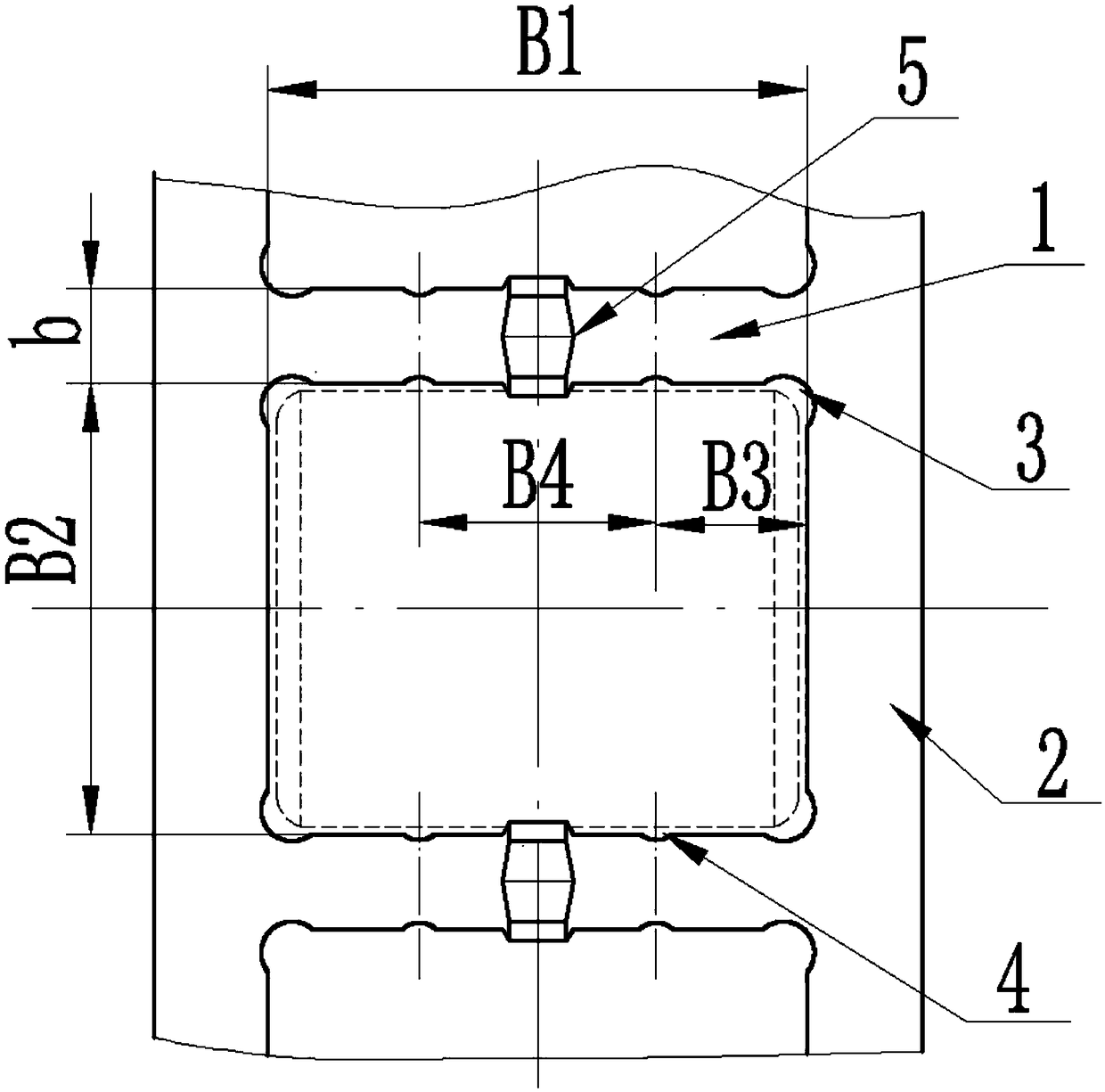

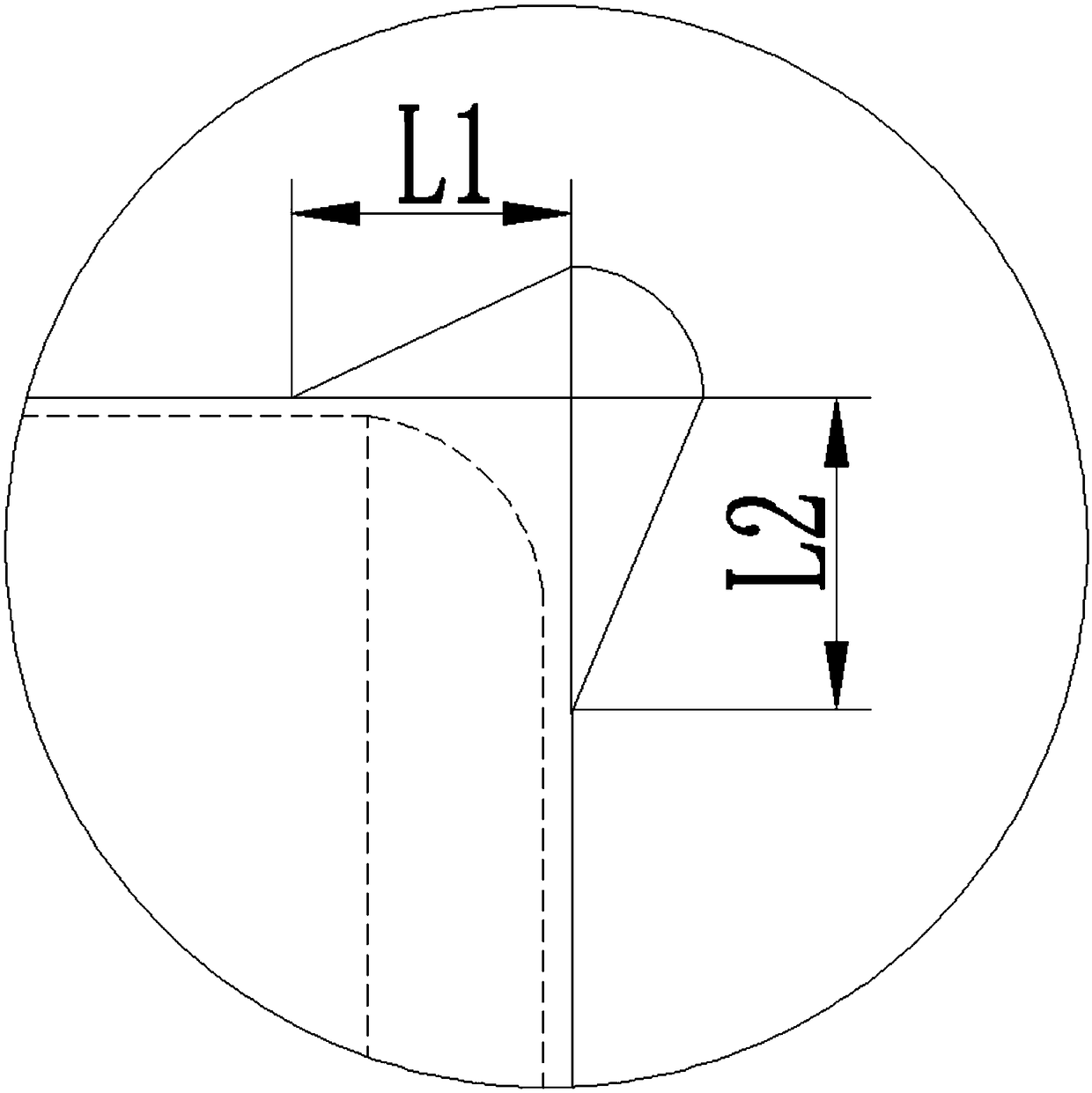

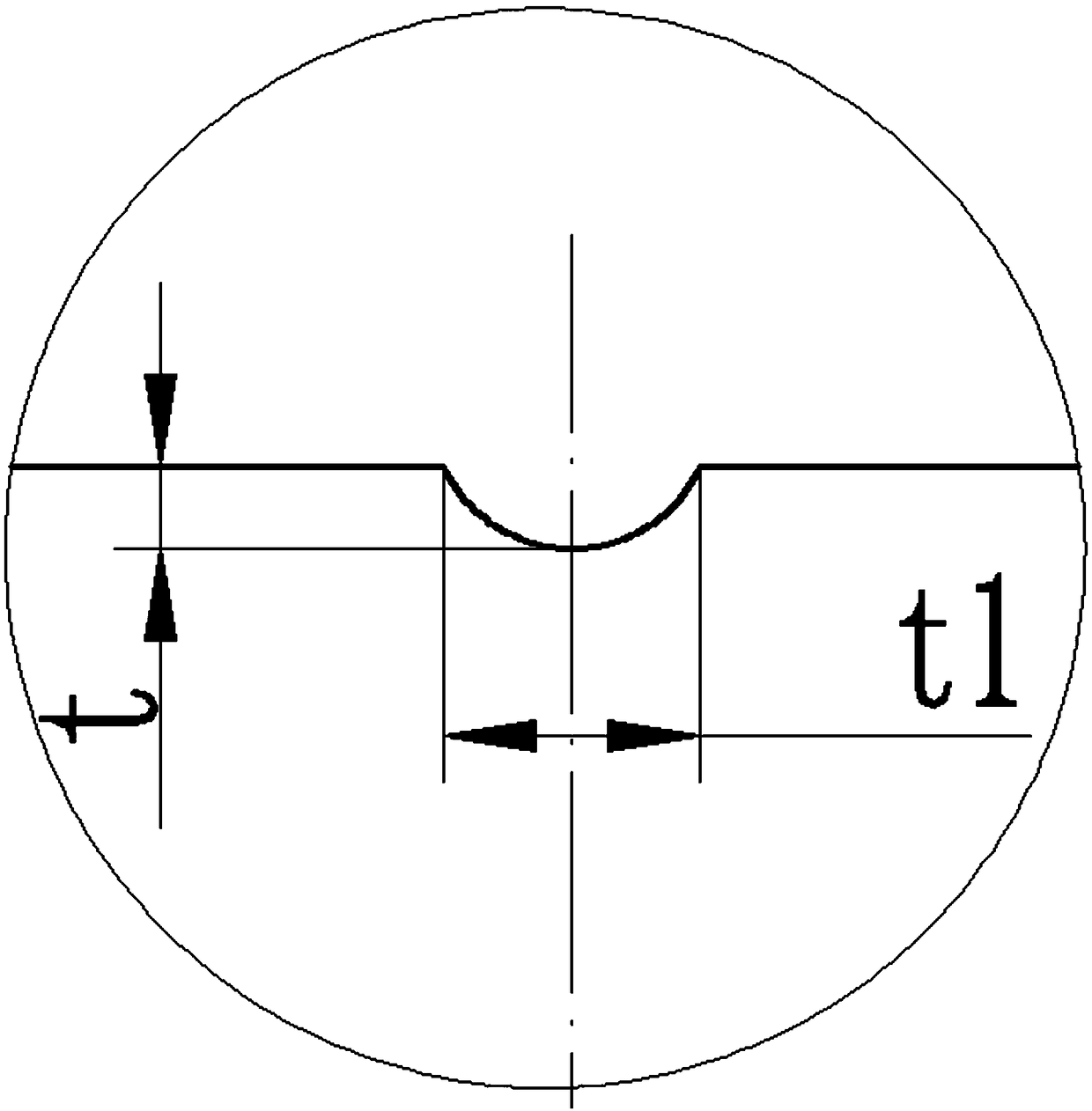

[0033] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. In this embodiment, a cylindrical roller bearing cage includes a body 2 and a beam 1, and a stress buffer groove 3 is processed at the transition position between the body 2 and the beam 1, and the stress buffer groove 3 is 2 / 3 to 3 / 4 circles, the beam 1 is processed with an oil groove 4, the oil groove 4 is a semicircle concave along the radial direction of the beam 1, the number of oil grooves 4 is N, and N is a positive integer.

[0034] Working principle: Design the stress buffer groove 3 at the transition position between the cage pocket beam and the lintel, the stress buffer groove 3 is 2 / 3 to 3 / 4 circular, because of its shape characteristics, the transition between the body 2 and the beam 1 The position stress is dispersed to avoid stress concentration and cracks due to insufficient size transition between the two. A longitudinal oil groove is d...

specific Embodiment approach 2

[0035] Specific embodiment 2: This embodiment is a further description of specific embodiment 1. In this embodiment, a single locking point 5 is provided in the middle of the beam 1 to ensure that the come out.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment is a further description of Embodiment 1. In this embodiment, the oil groove 4 is a longitudinal oil groove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com