Low-temperature tester

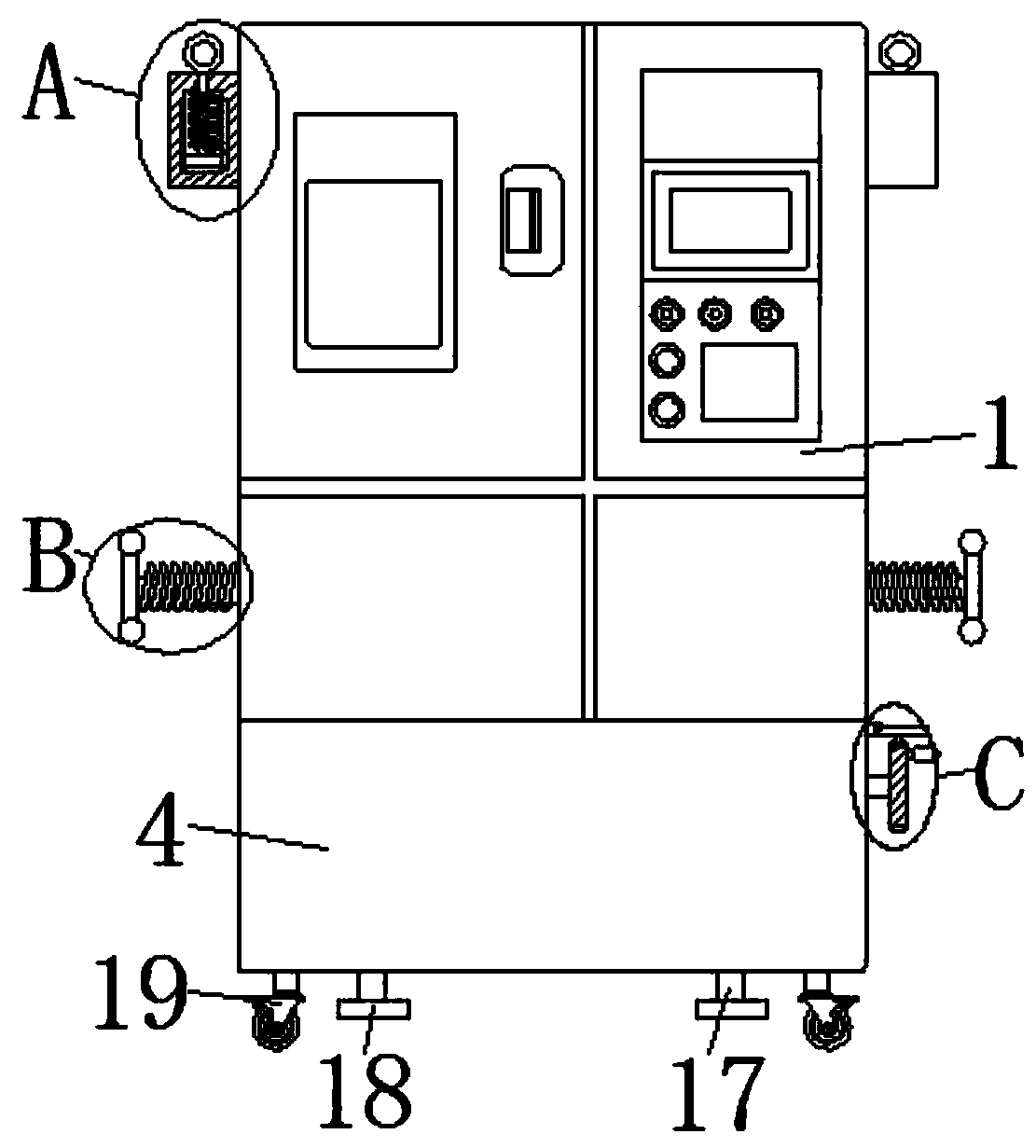

A low-temperature test and tester technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of reducing the experimental accuracy and poor stability of low-temperature testers, and achieve the effect of stable, good stability and convenient lifting of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

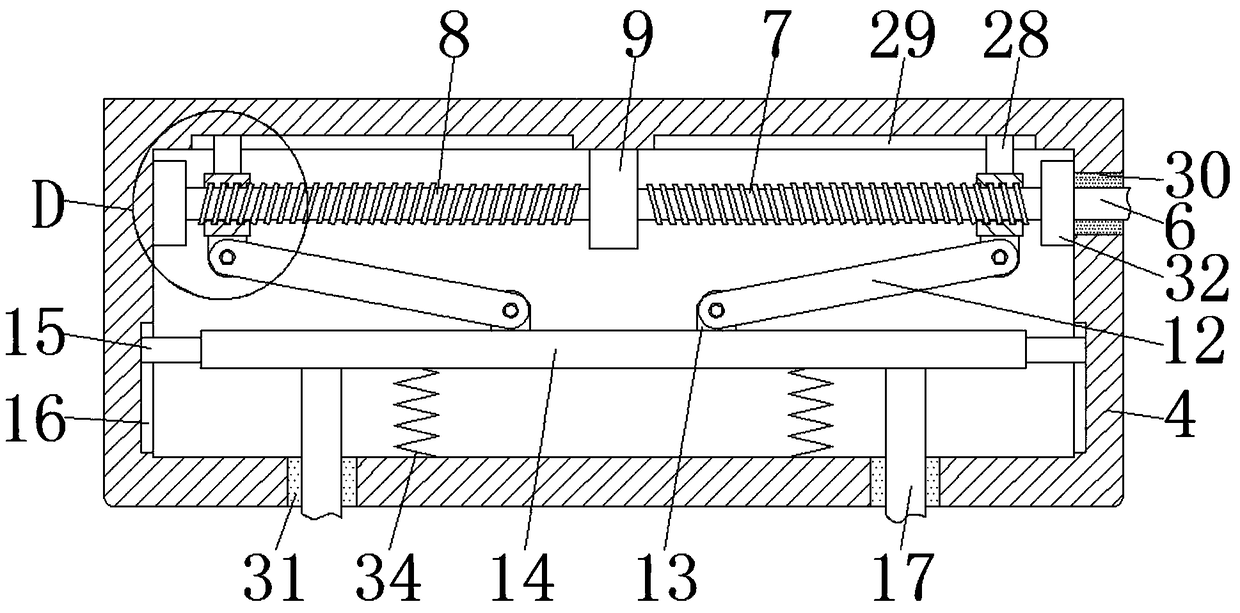

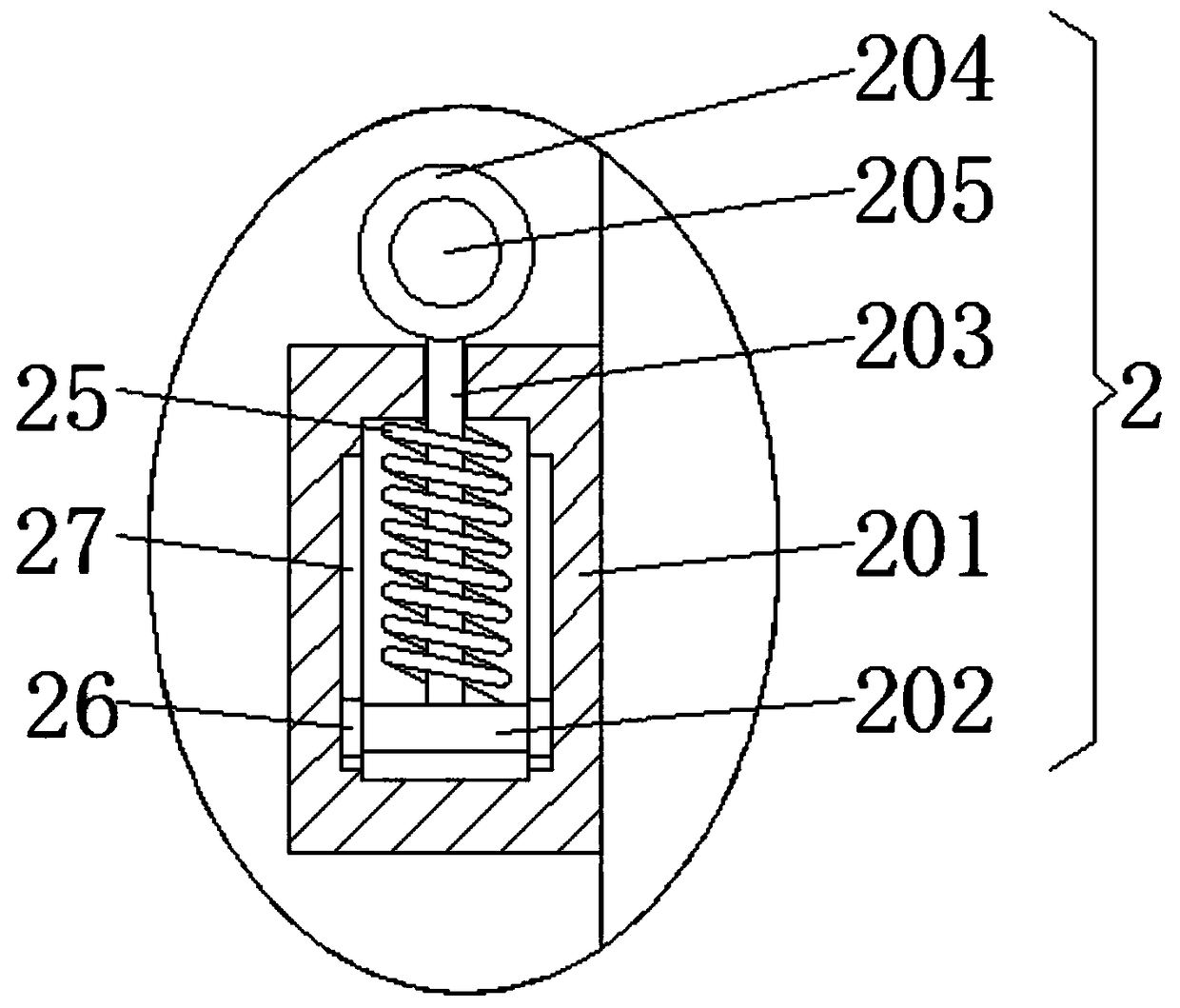

[0034] Embodiment 2: The difference from Embodiment 1 is that the hoisting mechanism 2 includes a card box 201, the side of the card box 201 close to the low temperature test device 1 is fixedly connected with the low temperature test device 1, and the inside of the card box 201 is movably connected with a slide plate 202, The top of the slide plate 202 is fixedly connected with a second fixed rod 203, the top of the second fixed rod 203 runs through the card box 201 and extends to the top of the card box 201, the top of the second fixed rod 203 is fixedly connected with a pull block 204, and the pull block 204 There is a through hole 205 in the inside. By setting the lifting mechanism 2, the disassembly and assembly on the market is more complicated and the height of the device will be increased. However, this structure can make it easier for users to lift the device without disassembly and assembly. The purpose of reducing the height of the device is to facilitate the movemen...

Embodiment 3

[0035] Embodiment 3: The difference from Embodiment 1 is that the anti-collision mechanism 3 includes a telescopic tube 301, the side of the telescopic tube 301 close to the low temperature test device 1 is fixedly connected to the low temperature test device 1, and the telescopic tube 301 is away from the side of the low temperature test device 1. The side is fixedly connected with the sixth fixed block 302, the top and the bottom of the sixth fixed block 302 are fixedly connected with the guide block 303, the surface of the telescopic tube 301 is provided with the first spring 304, by setting the anti-collision mechanism 3, the It is easy to cause force deviation, but this structure can make the device move in the direction of the telescopic tube 301 when it is hit by an external force, so as to achieve the purpose of uniform force, which is convenient for users to use and improves the service life of the device , increasing the practicability of the device.

Embodiment 4

[0036] Embodiment 4: The difference from Embodiment 2 is that: the surface of the second fixed rod 203 is covered with a second spring 25, both sides of the slide plate 202 are fixedly connected with a second slider 26, and both sides of the inner wall of the card box 201 are fixed. There is a second chute 27 for use with the second slider 26. By setting the second spring 25, the second slider 26 and the second chute 27, it is easy to cause the rotation of the second fixed rod 203 on the market, which is inconvenient. For hoisting, but this structure can avoid the rotation of the second fixed rod 203, and at the same time ensure that the second fixed rod 203 is in a fixed position, which is convenient for the user to hoist and improve the practicability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com