Electronic detonator control module structure

A control module and electronic detonator technology, applied in the field of pyrotechnics, can solve problems such as the influence of electronic detonator control module stability, increase the difficulty of other component layout, and reduce the reliability of circuit boards, so as to achieve good mechanical external force protection and improve Stability and reliability, the effect of reducing the difficulty of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

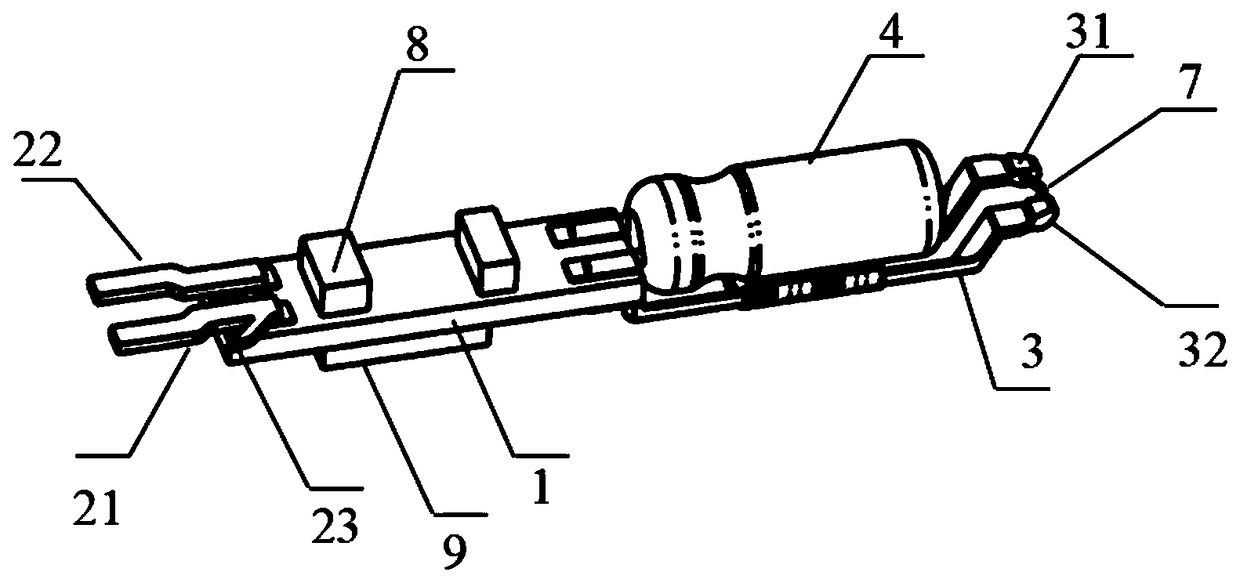

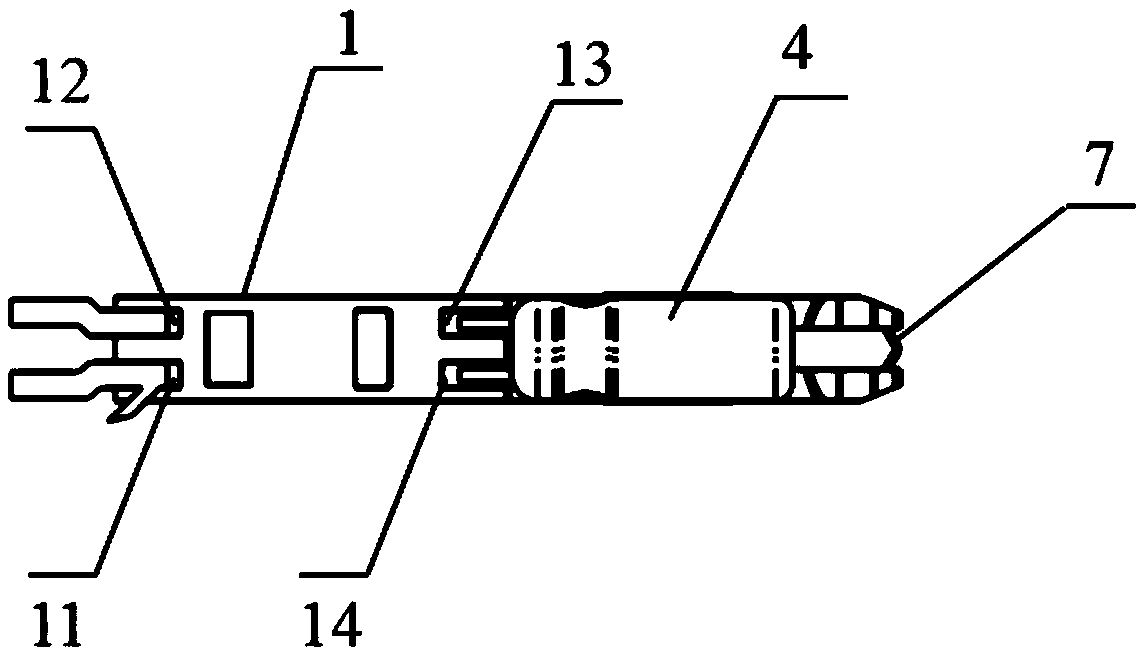

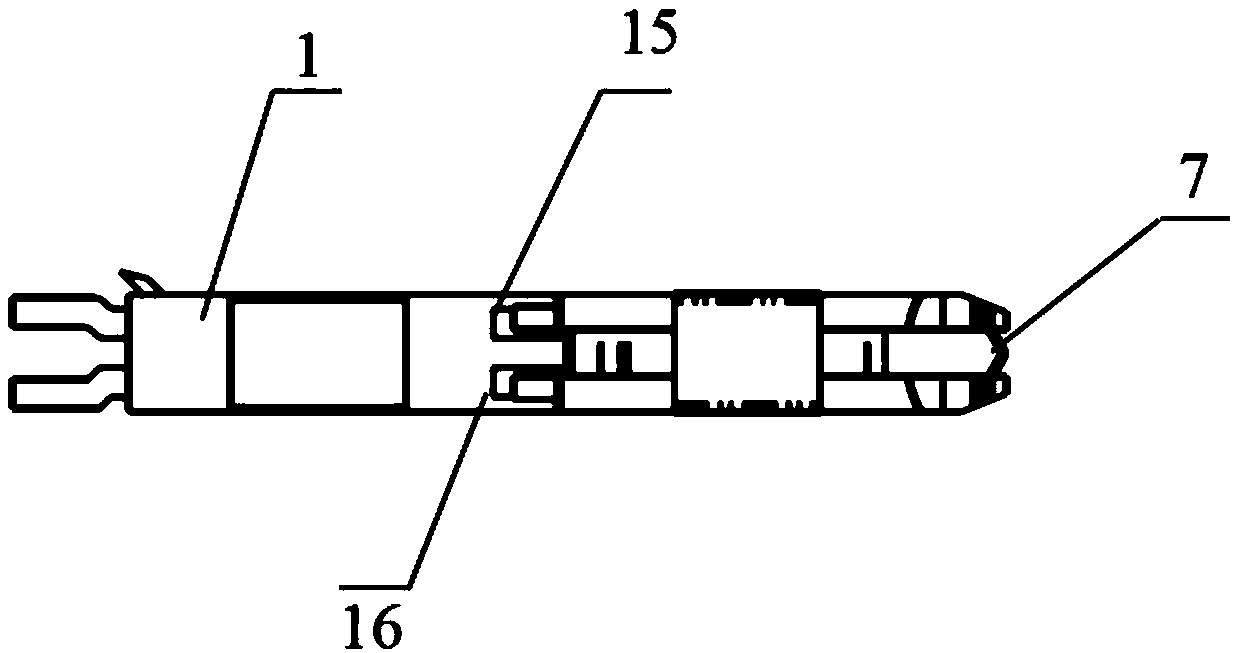

[0026] Embodiment of the present invention: electronic detonator control module structure, including circuit board 1, left leg input terminal 21, right leg input terminal 22 and capacitor support 3, is characterized in that: left leg input terminal 21 and right leg input Terminal 22 is respectively connected with one end of circuit board 1 by left foot wire pad 11 and right foot wire pad 12, capacitor support 3 is connected with the other end of circuit board 1 by left support pad 13 and right support pad 14, in The bottom of the end where the circuit board 1 is connected to the capacitor bracket 3 is provided with a left capacitor pad 15 and a right capacitor pad 16; the energy storage capacitor 4 is fixed on the capacitor bracket 3, and the two pins of the energy storage capacitor 4 are connected to the left capacitor The pad 15 is connected to the right capacitor pad 16; the other end of the capacitor support 3 is the left bridge wire crimp terminal 31 and the right bridge w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com