Insulated voltage-resistant test tool for power battery module

A power battery and module insulation technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the safety hazards of sharp corners at the welding point to the digital model, and the problems of bruising and metal particles attached to the battery during handling and moving , to achieve the effect of solving the micro-short circuit problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

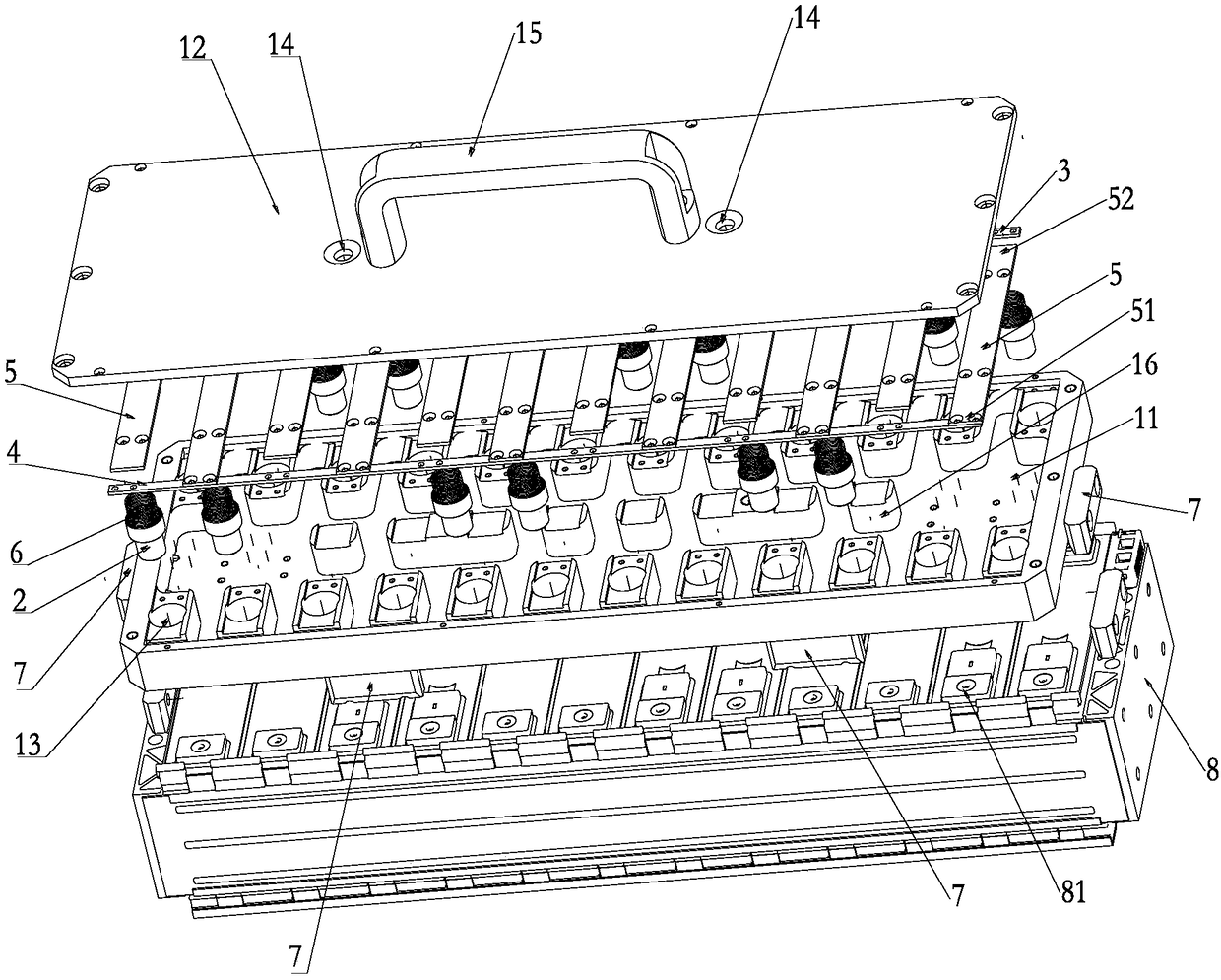

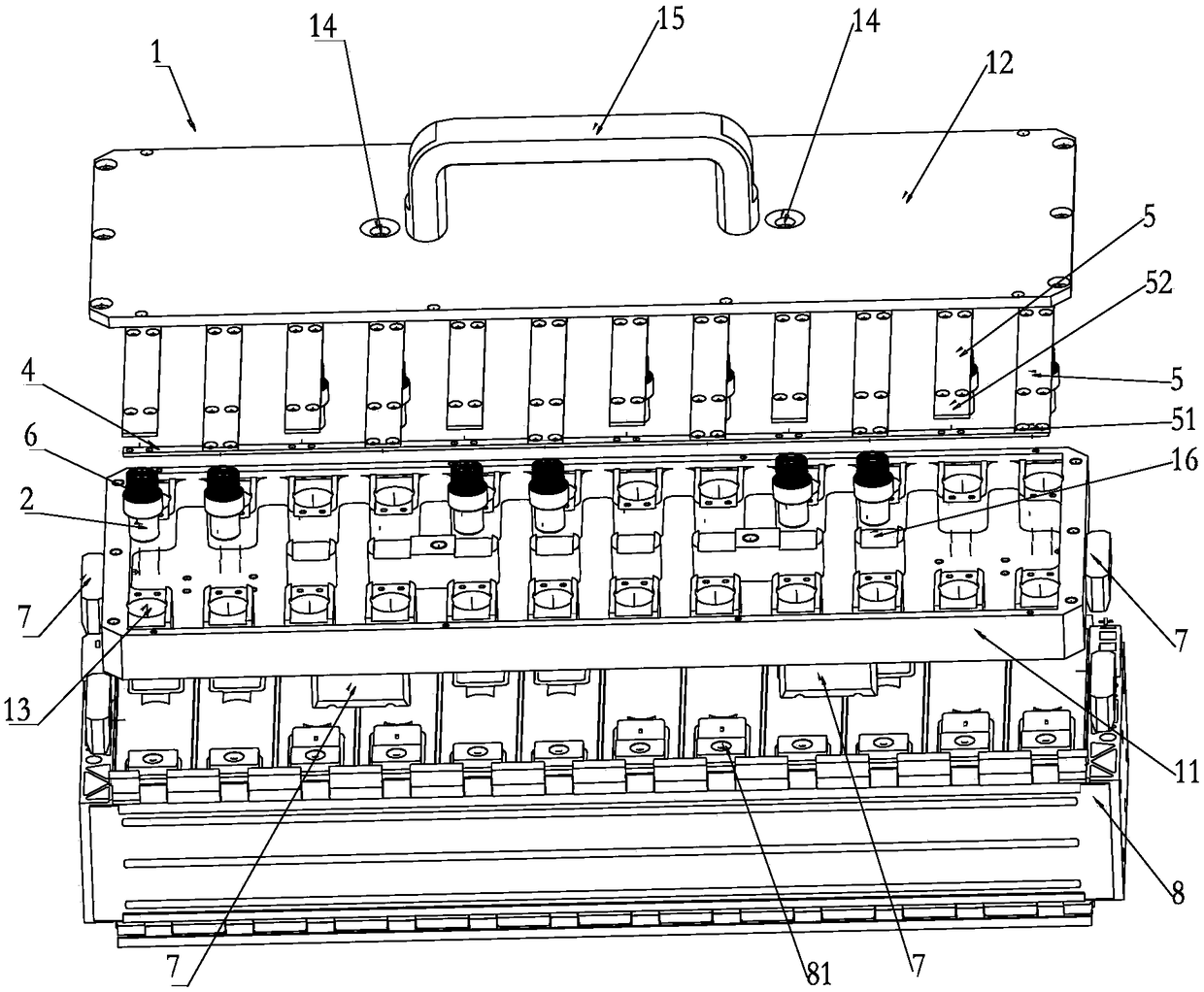

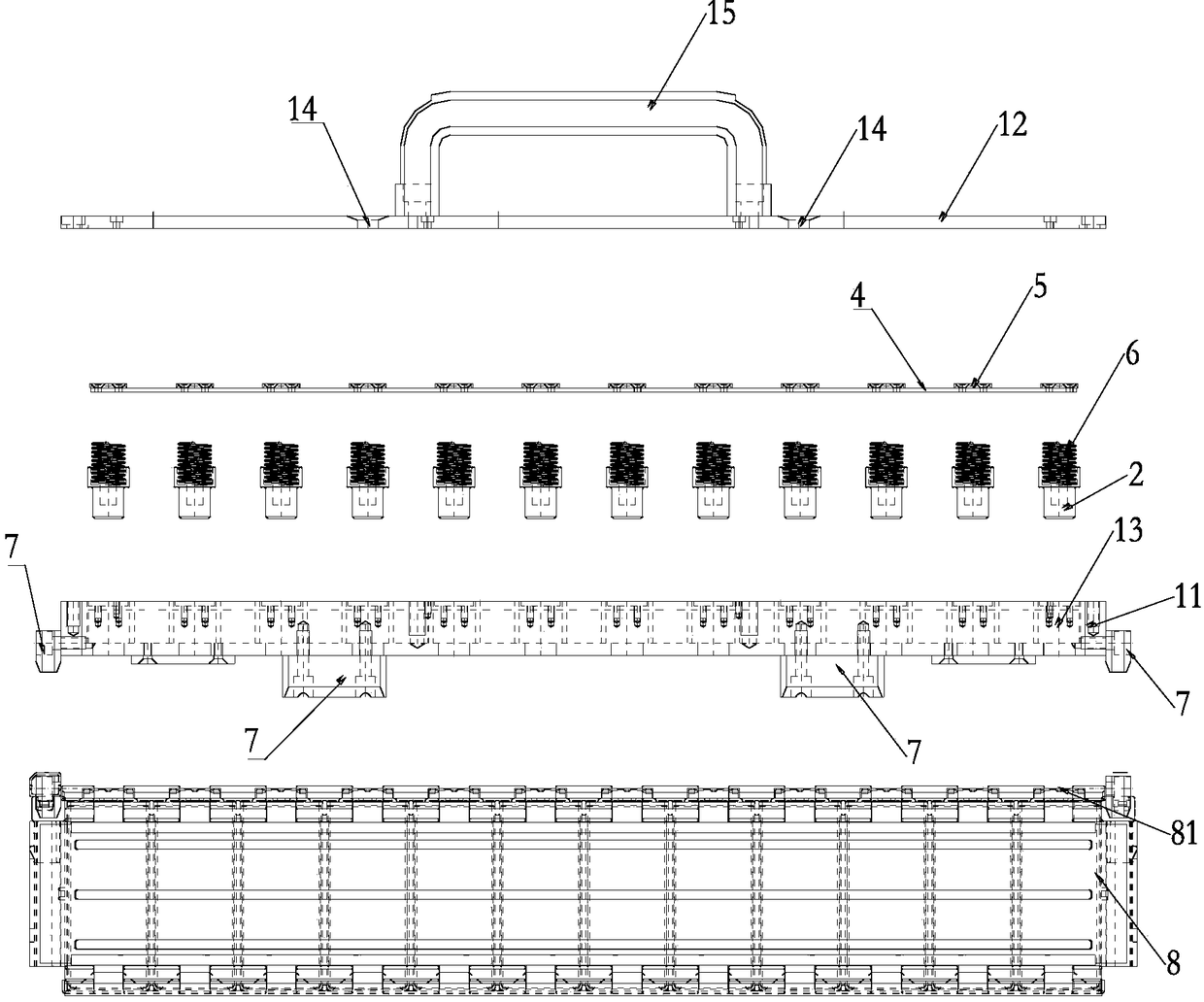

[0040] Implementation mode one: if figure 1 and figure 2 As shown, the two main road copper strips are respectively the first main road copper strip 3 and the second main road copper strip 4; several branch copper strips 5 are located between the first main road copper strip 3 and the second main road copper strip. Between the main road copper bars 4; the branch copper bars 5 connected to the first main road copper bars 3 and the branch copper bars 5 connected to the second main road copper bars 4 are alternately arranged one by one;

[0041] The connection end 51 of the branch copper strip 5 connected to the first main circuit copper strip 3 is connected with a test probe 2, and the branch copper strip 5 connected to the second main circuit copper strip 4 In addition, in order to make the connection more stable, the floating end 52 of the branch copper strip 5 connected to the end of the first main road copper strip 3 is connected with the test probe 2;

Embodiment approach 2

[0042]Embodiment 2: Two main circuit copper strips and several branch circuit copper strips 5 adopt the same connection method as in Embodiment 1, the difference lies in the connection position of the test probe 2. In this embodiment, all the branch circuit copper strips The test probe 2 is connected to the floating end 52 of the bar 5 .

[0043] In Embodiment 1 and Embodiment 2, a plurality of branch copper strips 5 are interlaced one by one, so that the battery cells in the power battery module 8 can be connected in parallel first and then in series, which is convenient for connection and detection.

Embodiment approach 3

[0044] Embodiment 3: The two main road copper bars are respectively the first main road copper bar 3 and the second main road copper bar 4; several branch copper bars 5 are located between the first main road copper bar 3 and the second main road copper bar. Between the two main road copper bars 4; the branch copper bars 5 connected to the first main road copper bars 3 and the branch copper bars 5 connected to the second main road copper bars 4 are alternately arranged in pairs;

[0045] The free end 52 or connecting end 51 of the branch copper bar 5 is connected with a test probe 2; One of the connecting ends 51 or the floating end 52 of the two branch copper strips 5 is connected with the test probe 2;

[0046] Embodiment 3 The multi-branch copper strips 5 are arranged alternately in pairs, and the battery cells in the power battery module 8 are first connected in series and then in parallel, so as to facilitate connection and detection.

[0047] A preferred solution of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com