Method for automatically recognizing hob failure form of numerical control gear hobbing machine

A technology of automatic identification and gear hobbing machine, applied in the direction of metal processing machinery parts, metal processing equipment, measuring/indicating equipment, etc., to reduce labor costs, reduce dependence on professional skills, and realize the effect of online real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples.

[0027] In this embodiment, the method for automatic recognition of the failure mode of the hob of the CNC gear hobbing machine is characterized in that it includes the following steps:

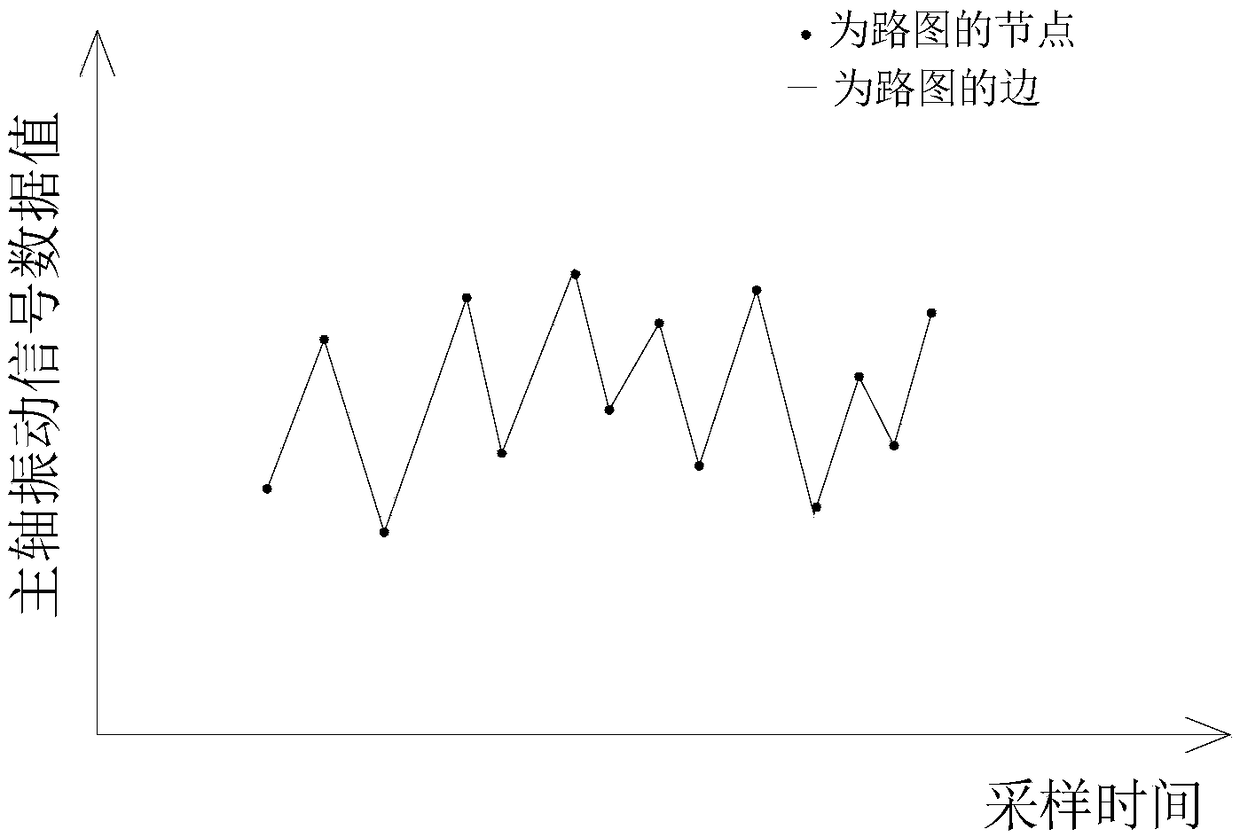

[0028] Step 1, obtain the spindle vibration signal: at the same sampling frequency f s Next, the vibration simulation quantity of the main shaft during the gear hobbing process is collected in real time through the embedded vibration acceleration sensor. The embedded vibration acceleration sensor described in this embodiment is a bearing embedded at the end of the main shaft during the assembly and manufacturing process of the CNC gear hobbing machine. In the seat; then use the PLC controller of the CNC gear hobbing machine to perform A / D conversion processing on the vibration analog value to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com