Complete collector-shoe gear for oil field oil pipe

A full current collector and tubing technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of polluted environment, measurement error, complex structure, etc., achieve low power consumption and avoid leakage liquid, improving stability and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

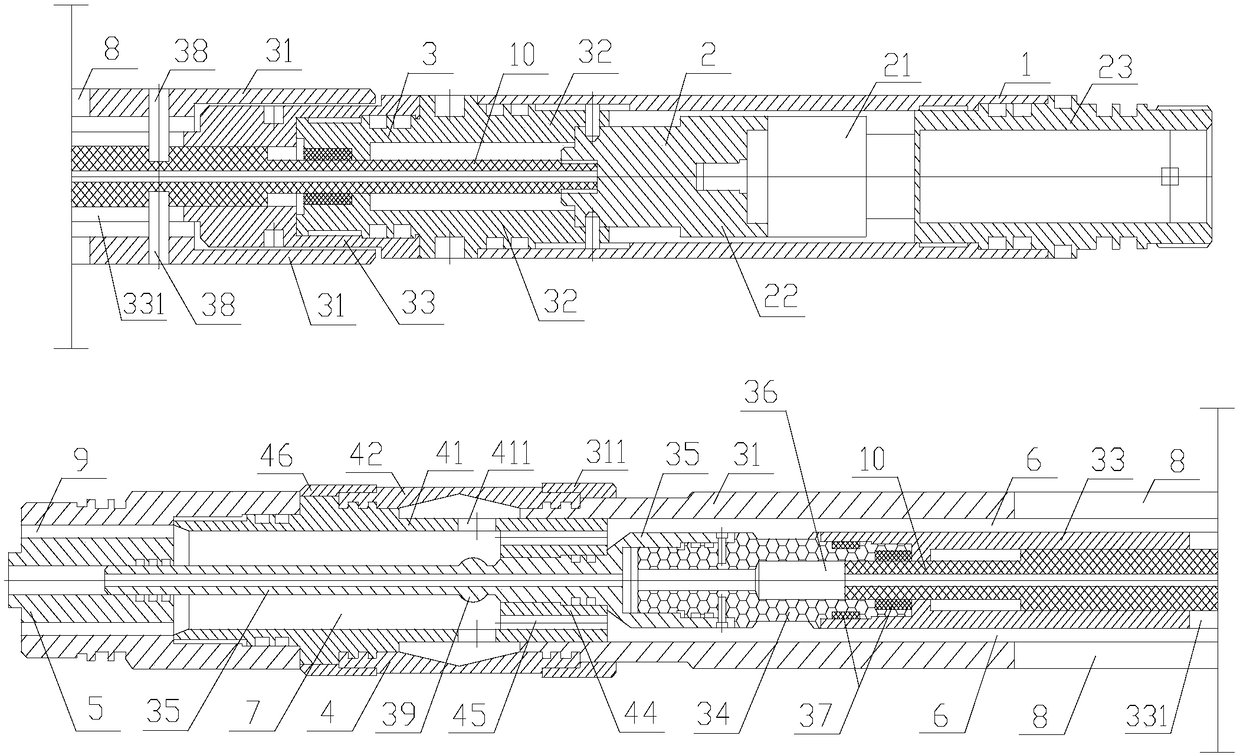

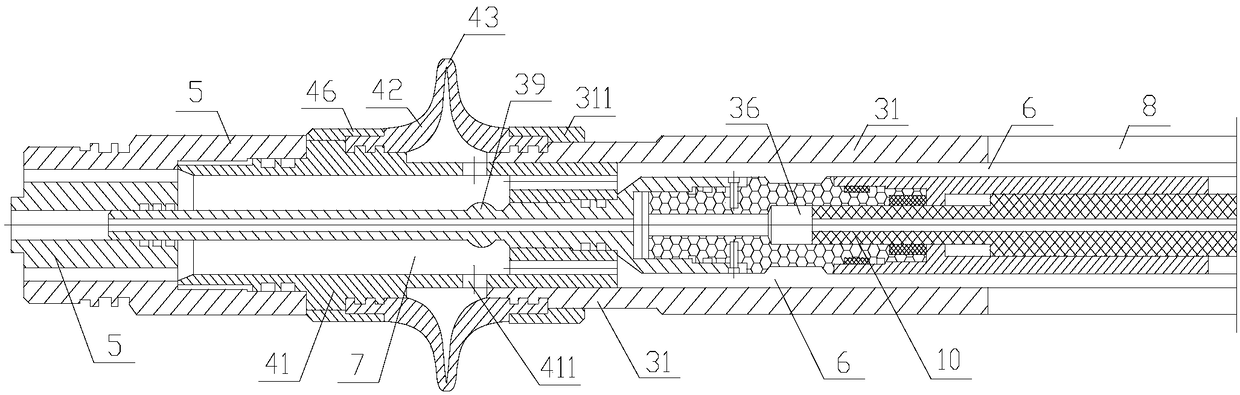

[0029] Such as figure 1 , 2 As shown, the present invention is a full current collector for oilfield tubing, including a casing 1, a pushing mechanism 2, a transmission mechanism 3, a sealing mechanism 4, and a lower outlet joint 5, and the pushing mechanism 2 is arranged in the casing 1 , the push mechanism 2 pushes the transmission mechanism 3, and the transmission mechanism 3 pushes the sealing mechanism 4 to seal off the inner wall of the oil pipe. The transmission mechanism 3 includes a push sleeve 31, and the sealing mechanism 4 includes a sealing cylinder 41 and an elastic sealing ring 42. Cylindrical, one end is fixed on the outer wall of the sealing cylinder 41, the other end is fixed on the outer wall of the tail end of the push sleeve 31, the inner wall of the push sleeve 31 is in sliding contact with the outer wall of the sealing cylinder 41, and the elastic sealing ring 42 is pushed by the push sleeve 31. A circular sealing piece 43 protrudes outward.

[0030] T...

Embodiment 2

[0037] Such as figure 1 , 2 As shown, the present invention is a full current collector for oilfield tubing, including a casing 1, a pushing mechanism 2, a transmission mechanism 3, a sealing mechanism 4, and a lower outlet joint 5, and the pushing mechanism 2 is arranged in the casing 1 , the push mechanism 2 pushes the transmission mechanism 3, and the transmission mechanism 3 pushes the sealing mechanism 4 to seal off the inner wall of the oil pipe. The transmission mechanism 3 includes a push sleeve 31, and the sealing mechanism 4 includes a sealing cylinder 41 and an elastic sealing ring 42. Cylindrical, one end is fixed on the outer wall of the sealing cylinder 41, the other end is fixed on the outer wall of the tail end of the push sleeve 31, the inner wall of the push sleeve 31 is in sliding contact with the outer wall of the sealing cylinder 41, and the elastic sealing ring 42 is pushed by the push sleeve 31. A circular sealing piece 43 protrudes outward.

[0038] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com