Automobile instrument fault automatic detection system and method

A technology of automatic detection and automotive instrumentation, which is applied in the direction of test/monitoring control system, vehicle test, general control system, etc. It can solve problems such as long test cycle, low work efficiency, and inability to make accurate judgments on product quality, so as to achieve improvement The effect of test accuracy, test data reliability and shorten test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

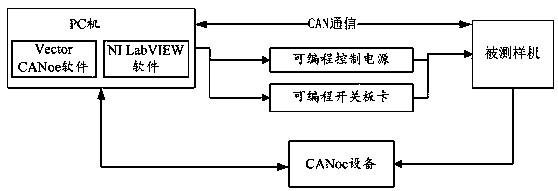

[0034] An automatic detection system for automobile meter faults, such as figure 1 Shown: Including PC, CANoe device, programmable control power supply and programmable switch board, PC is connected to CANoe device, programmable control power supply and programmable switch board respectively, CANoe device, programmable control power supply and programmable switch board The switch boards are respectively connected with the tested prototype; at the same time, the PC is also connected with the tested prototype through CAN communication.

[0035] In this system, the PC has built-in Vector CANoe software or NI LabVIEW software, which is used to control programmable control power supply, programmable switch board and CAN signal to simulate manufacturing fault types through Vector CANoe software or NI LabVIEW software, and through The CANoe device obtains the fault code information and fault occurrence time embodied by the tested prototype; the CANoe device is used to detect the CAN ...

Embodiment 2

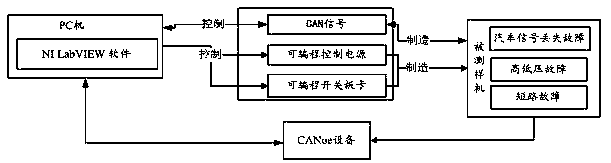

[0041] An automatic detection method based on an automatic detection system for automobile instrument failures, such as figure 2 Shown: including the following steps:

[0042] S10. The PC sends the fault code to the programmable control power supply or programmable switch board through its built-in NI LabVIEW software, so that it can simulate the fault type corresponding to the fault code, and record the fault type and fault generation time.

[0043]This step is specifically, the PC sends the fault codes to the programmable control power supply or the programmable switch board through its built-in NI LabVIEW software, and controls the programmable control power supply or the programmable switch board to simulate the manufacturing and fault codes. Corresponding fault types, at the same time, NI LabVIEW software can also send fault codes to CAN communication and simulate and manufacture car signal loss faults by controlling CAN signals, and record fault types and fault generati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com