Processing tool for PCB product copper block browning and storage vehicle thereof

A technology for storing carts and copper blocks, applied in trolleys, motor vehicles, multi-axle carts, etc., can solve the problems of copper blocks falling into the tank, unable to be browned, and accessories copper blocks unable to be produced normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

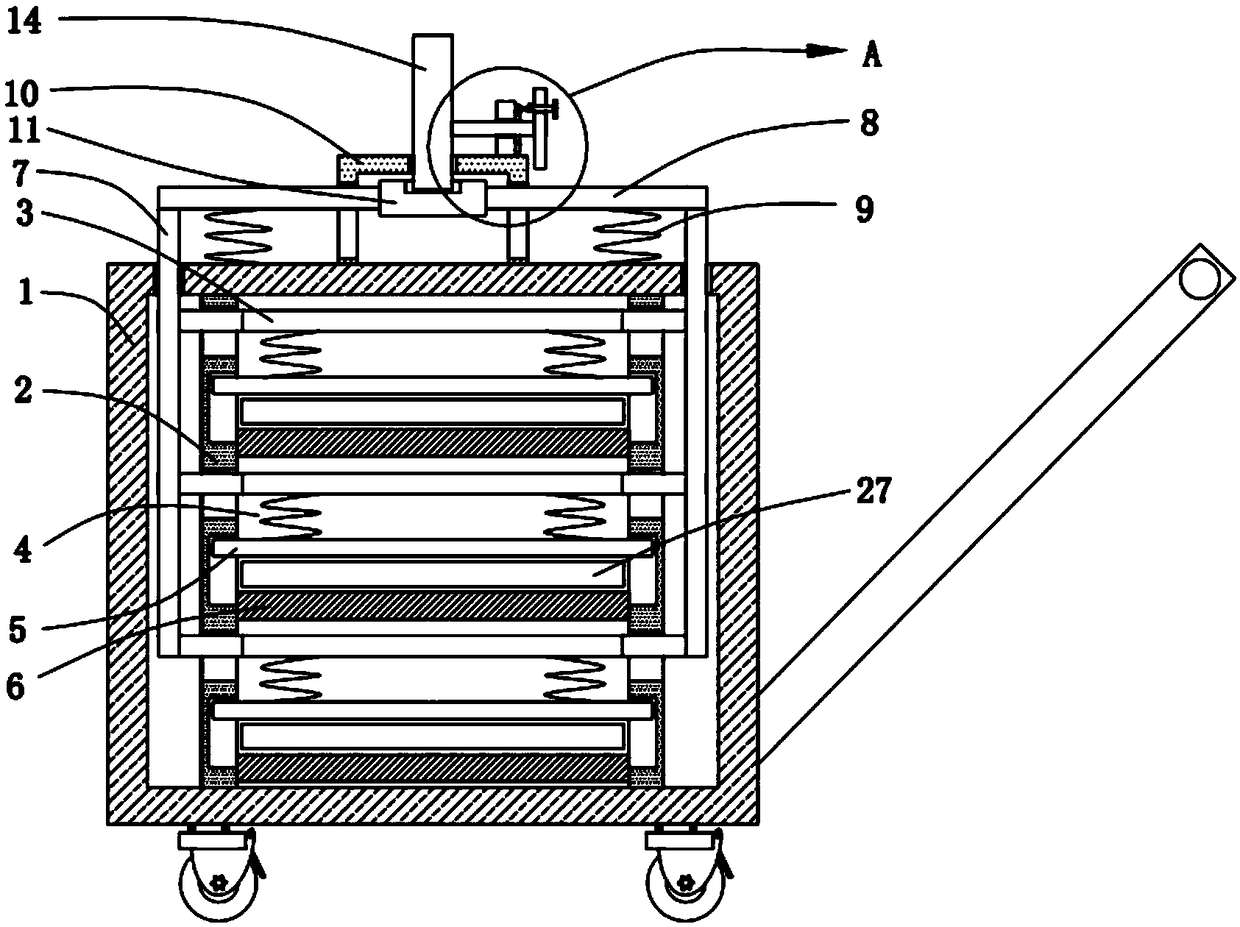

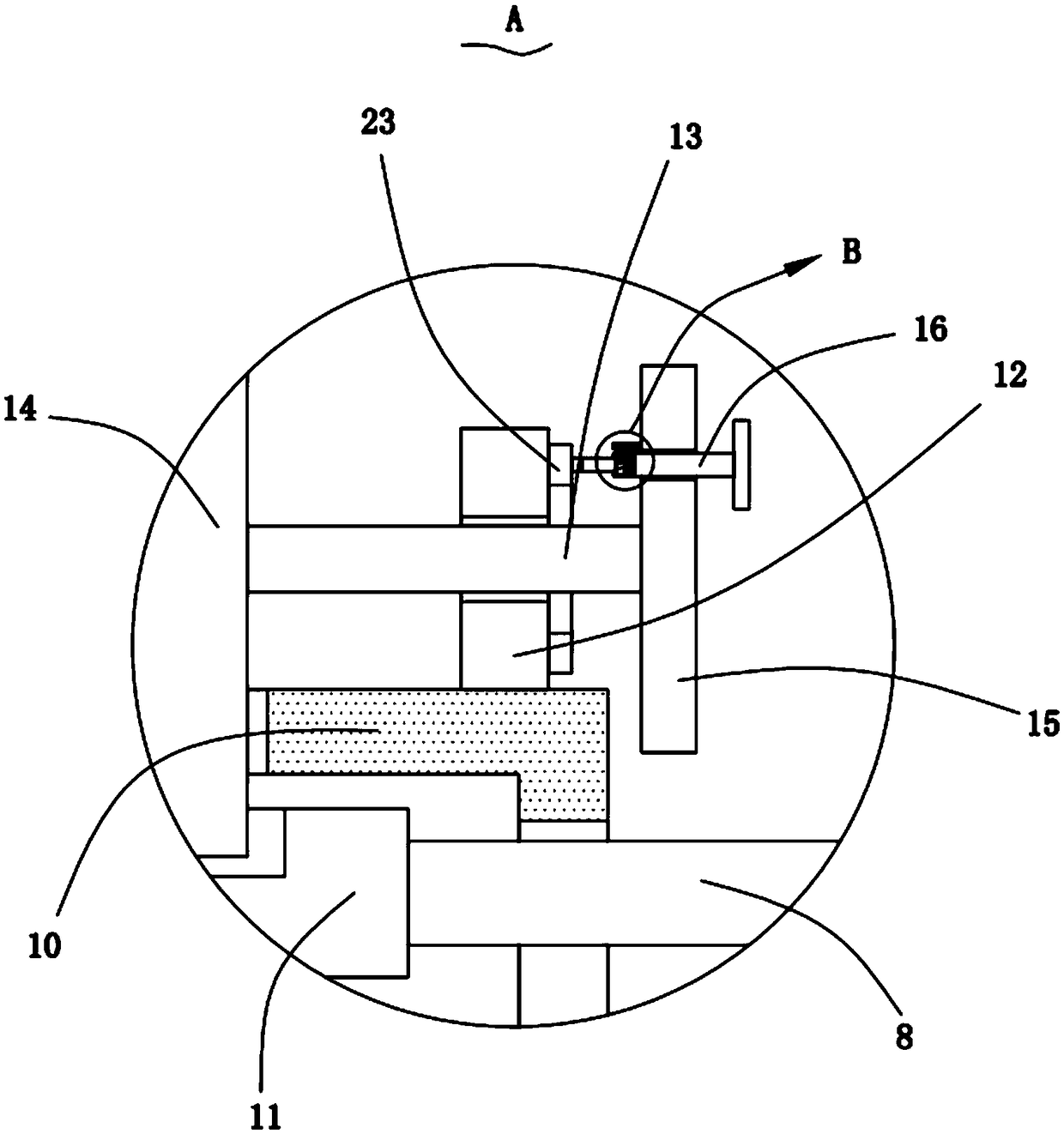

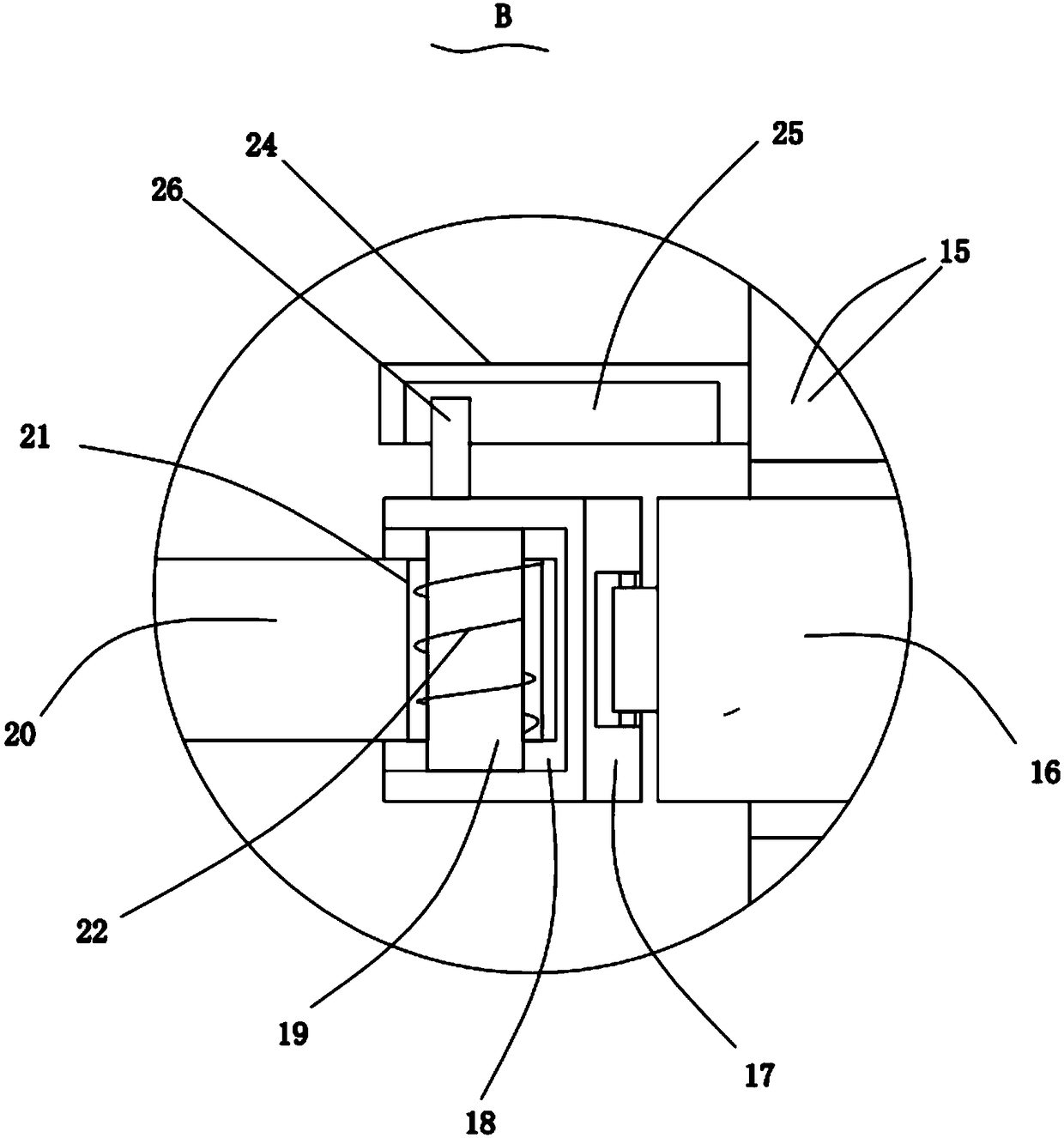

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the processing fixture and storage car for the browning of PCB product copper blocks provided by the present invention; figure 2 for figure 1 Schematic diagram of the enlarged structure of part A shown; image 3 for figure 2 Schematic diagram of the enlarged structure of part B shown; Figure 4 for figure 1 The top sectional schematic diagram shown; Figure 5 for Figure 4 Schematic diagram of the enlarged structure of part C shown; Image 6 It is a structural schematic diagram of the ring rack in the present invention; Figure 7 It is a top view structural schematic diagram of the bearing fixture plate in the present invention; Figure 8It is a front view cross-sectional structural schematic diagram of the carrying fixture plate in the present invention. The processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com