Washing machine

A cleaning machine and spray arm technology, applied in the field of cleaning machines, can solve the problems of being difficult to apply to household dishwashers and the structure of dishwashers, and achieve the effect of avoiding bubble burst failure and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

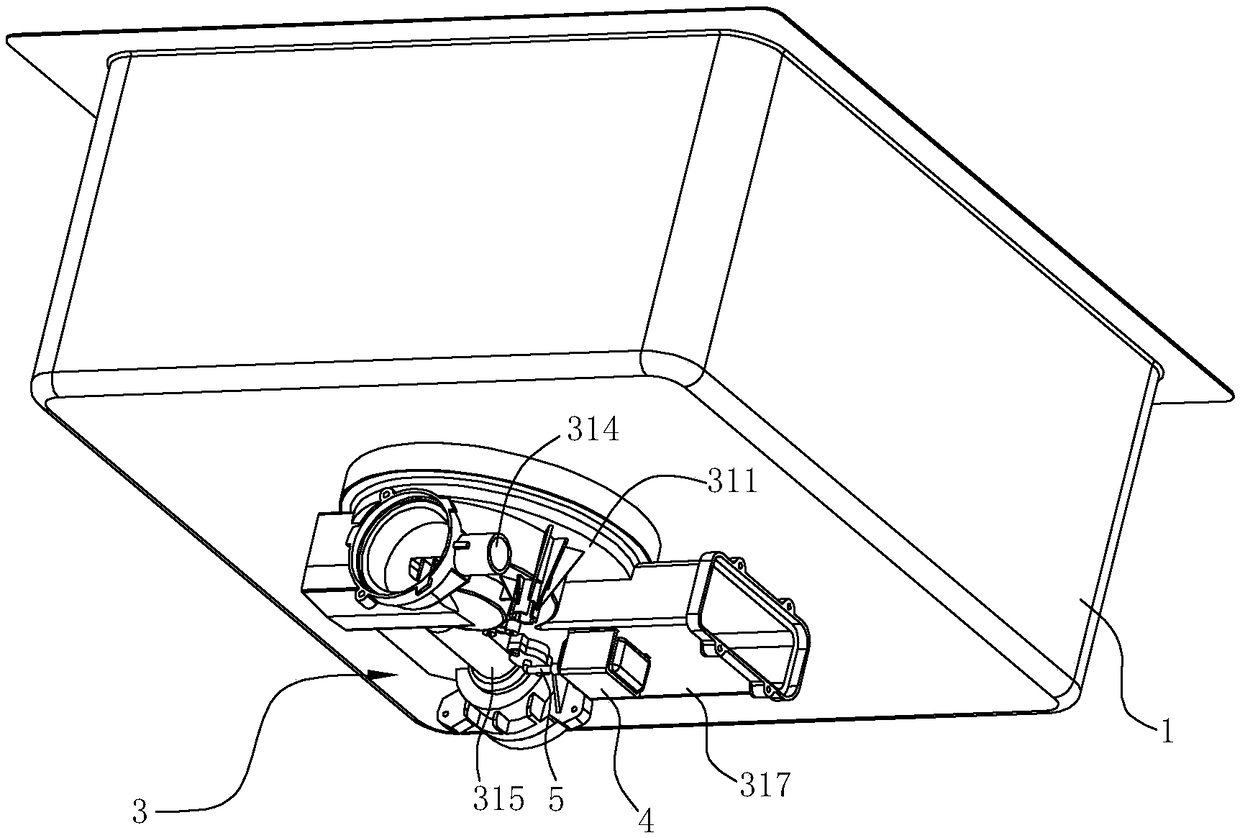

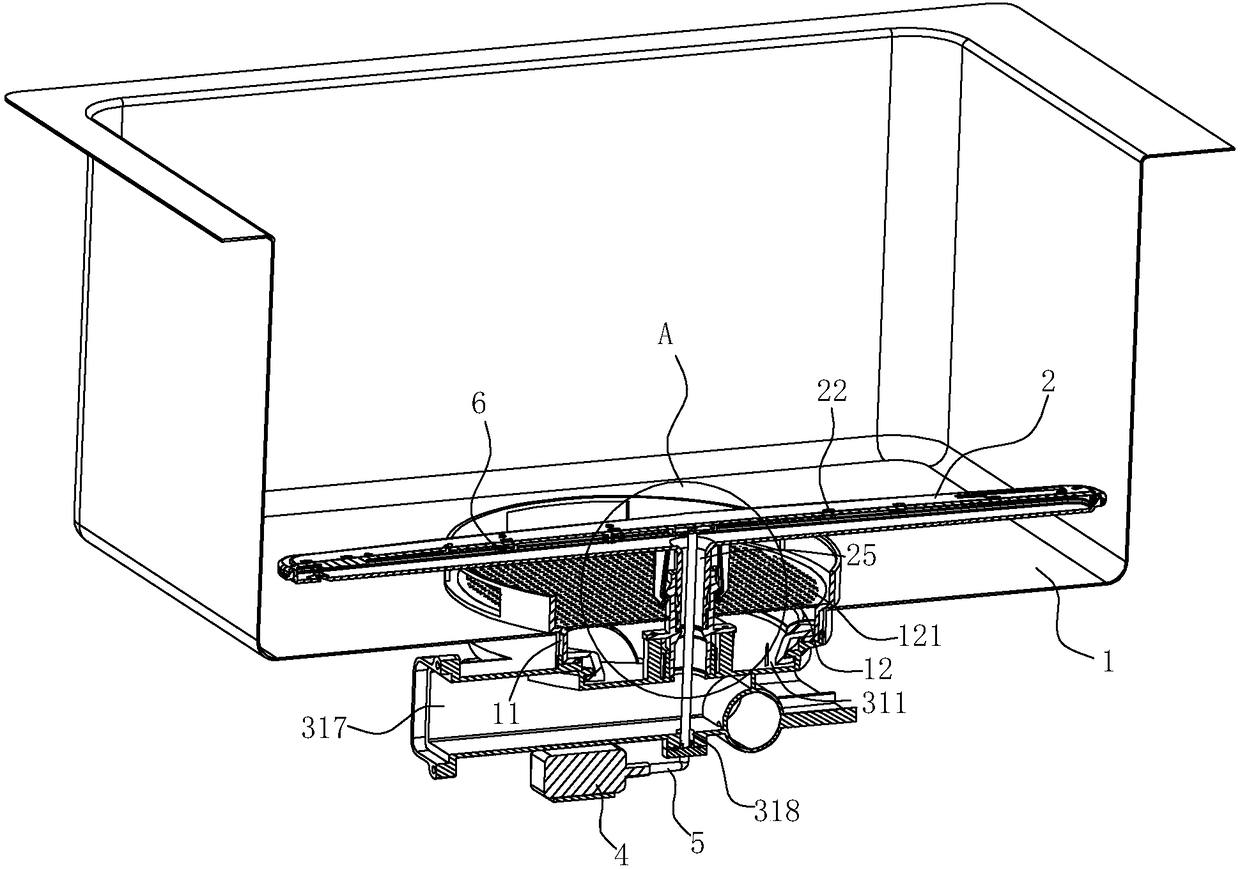

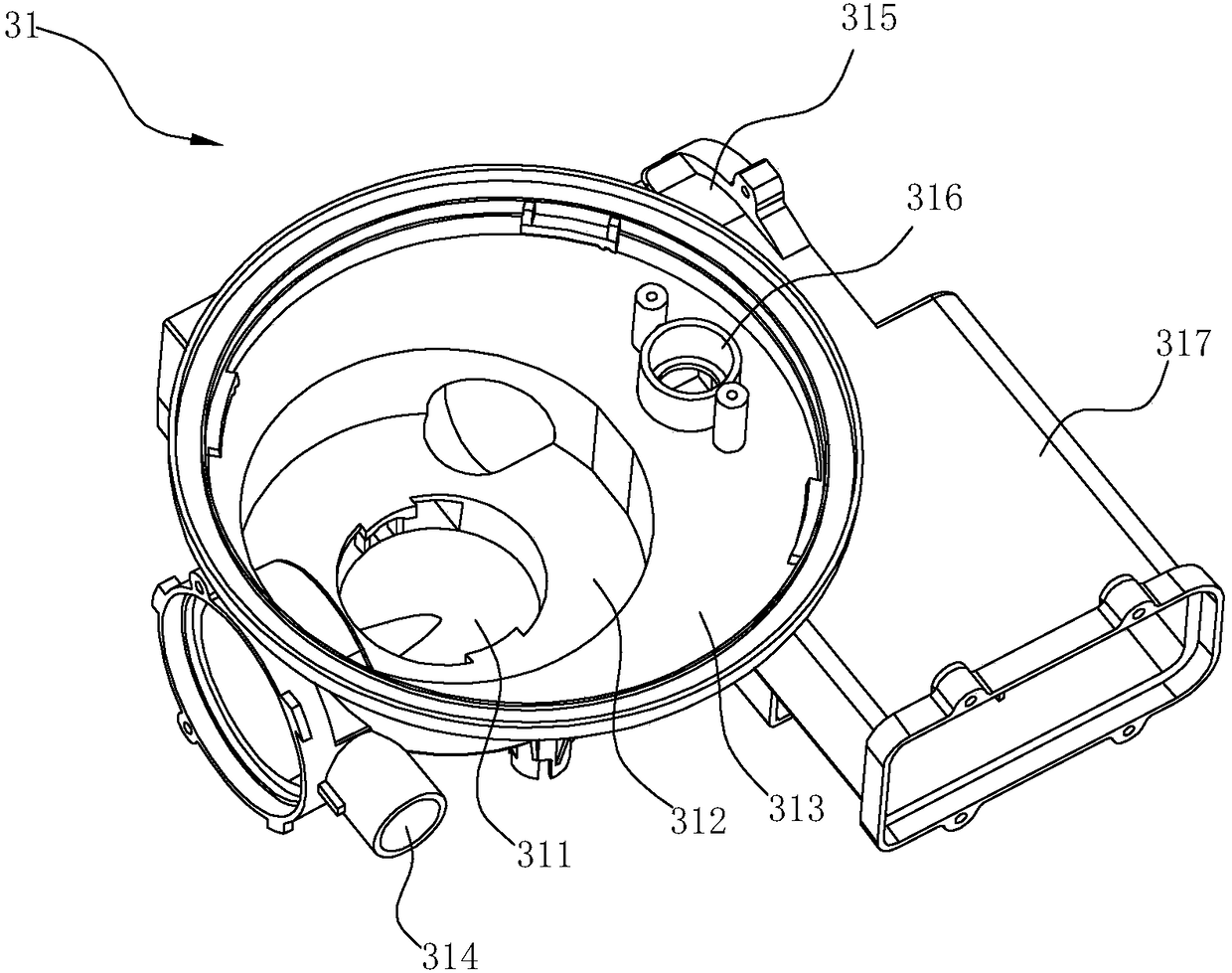

[0026] Such as Figure 1~6 As shown, the washing machine of the present embodiment comprises a casing 1, a spray arm 2, a power assembly 3, an air pump 4 and an air duct 5, and the power assembly 3 is used to pump water in the casing 1 into the spray arm 2, and spray The spray arm 2 is arranged in the box body 1 , and the power assembly 3 is connected under the spray arm 2 . The air pump 4 is arranged on the outside of the box body 1, the intake end of the air guide pipe 5 is connected with the air pump 4, the output end of the air guide pipe 5 extends into the spray arm 2, and the spray arm 2 is provided with an output port with the air guide pipe 5. The air collecting chamber 21 connected with the ends, the air collecting chamber 21 is provided with a gas guide channel 23 extending toward the water outlet hole 22 of the spray arm 2 .

[0027] In this embodiment, the spray arm 2 has a flow channel 24 extending from the middle to both ends respectively. The spray arm 2 is pro...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is only: as Figure 7 As shown, according to the fluid flow direction, the end of the gas guiding channel 23 in this embodiment is located upstream of the water outlet hole 22, and the gas guiding channel 23 in this embodiment is not provided with a branch channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com