A kind of anti-oxidation and moisturizing liquid crystal composition and its preparation method and application

A liquid crystal composition, anti-oxidation technology, applied in the direction of cosmetic preparations, cosmetics, pharmaceutical formulations, etc., to achieve the effect of complete liquid crystal structure, enhanced hydration, and remarkable anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

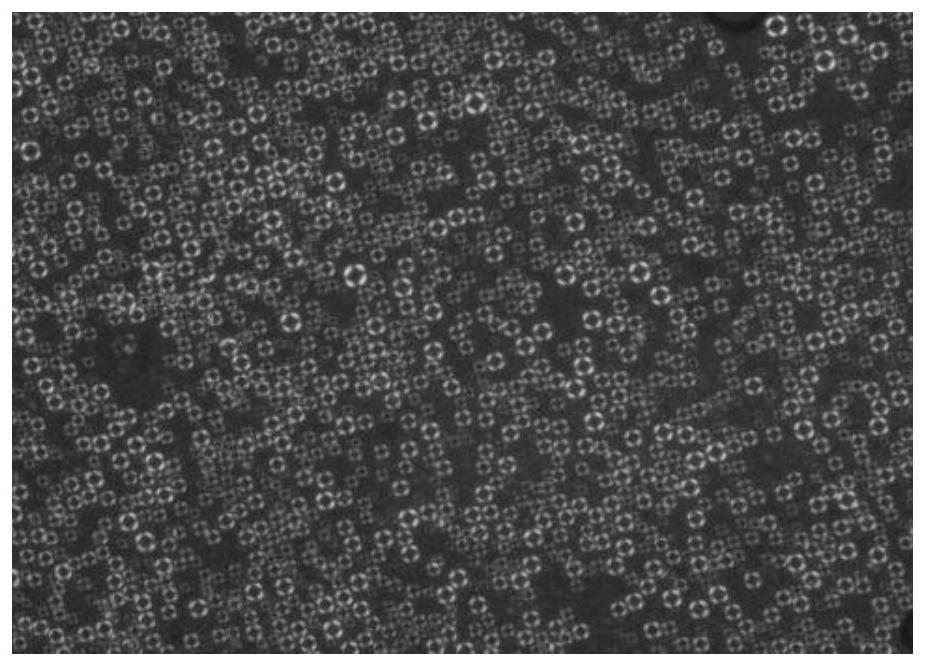

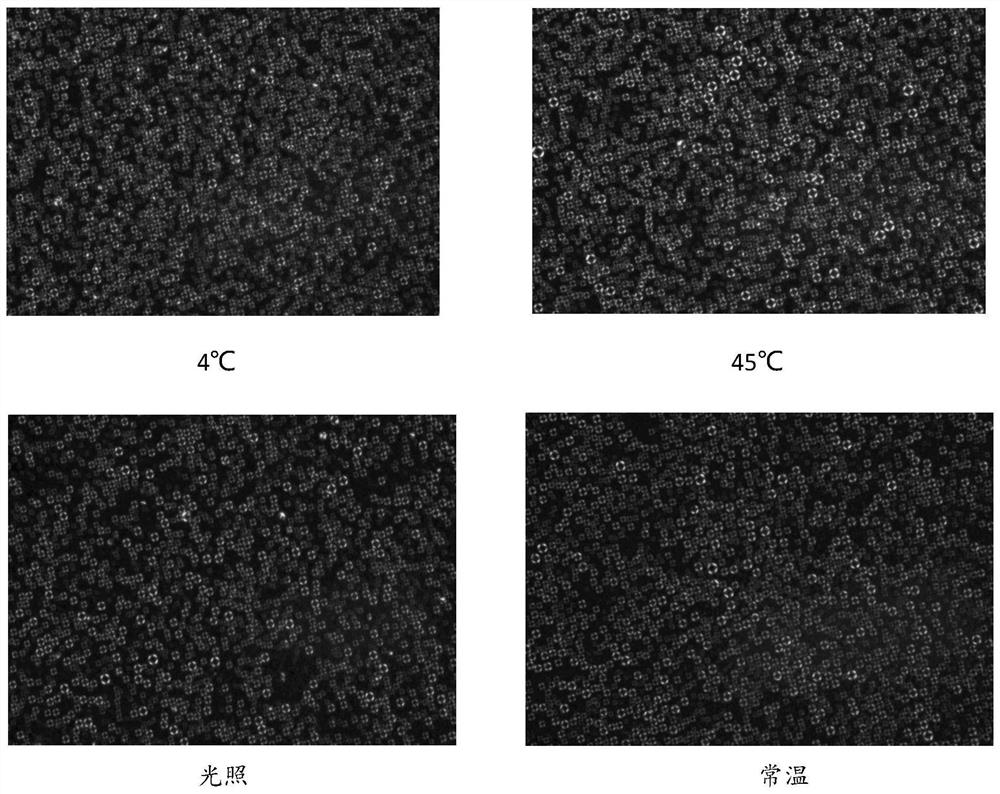

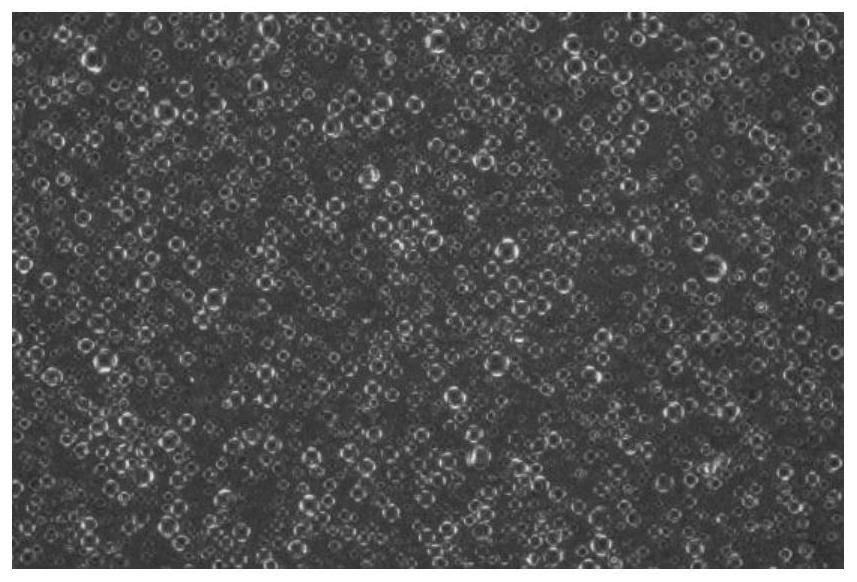

Image

Examples

Embodiment 1

[0058] Embodiment 1: prepare liquid crystal composition of the present invention

[0059] The mass percentage content is 0.5% milk thistle seed oil, 2% C14-22 alcohol / C12-20 alkyl glucoside, 1% hydrogenated lecithin, 1% ceteareth-6 , 5% simethicone, 2% caprylic / capric glycerides, and 3% isononyl isononanoate were stirred and mixed at a stirring speed of 300 rpm for 25 min in a water bath at 35 °C to obtain a uniform oil phase;

[0060] Mix 0.01% Ophiopogon japonicus polysaccharide, 0.1% polyacrylamide / C13-14 isoparaffin / lauryl ether-7, 0.2% gelatin and the rest of water, in a water bath at 35°C, at 300 rpm Stir and mix at a stirring speed of 25 min to obtain a homogeneous aqueous phase;

[0061] The oil phase was quickly added to the water phase, and sheared at 4000 rpm for 5 min to obtain liquid crystal colostrum;

[0062] Cool the liquid crystal colostrum to 25°C, add 0.5% phenoxyethanol, stir and mix at a stirring speed of 550 rpm for 10 minutes, and obtain an antioxidan...

Embodiment 2

[0063] Embodiment 2: prepare liquid crystal composition of the present invention

[0064] The mass percentage content is 8% milk thistle seed oil, 4% coconut-based glucoside and coconut oil alcohol, 2% arachidyl alcohol glucoside, 1% hydrogenated lecithin, 5% cetearyl alcohol Polyether-6, 1% mineral oil, 5% polycyclopentadimethylsiloxane, 5% caprylic acid cocoa butter were stirred and mixed for 30 min at a stirring speed of 200 rpm in a water bath at 65 °C , to obtain a homogeneous oil phase;

[0065] Mix 3% Ophiopogon japonicus polysaccharide, 1% hydroxyethyl acrylate / sodium acryloyl dimethyl taurate copolymer, 0.01% hydroxypropyl methylcellulose and the rest of the water, and mix them in a water bath at 65°C Next, stir and mix with a stirring speed of 200 rpm for 30min to obtain a homogeneous aqueous phase;

[0066] The oil phase is quickly added to the water phase, and sheared at 2000 rpm for 20 min to obtain liquid crystal colostrum;

[0067] Cool the liquid crystal col...

Embodiment 3

[0068] Embodiment 3: prepare liquid crystal composition of the present invention

[0069] The mass percentage content is 1% milk thistle seed oil, 6% eicosyl behenyl alcohol and eicosyl glucoside, 2% PEG-20 methyl glucose sesquistearate Esters, 12% Cetostearyl Alcohol and Cocoyl Glucoside, 2% Cetostearyl Alcohol, 10% Squalane, 10% Octyl Butyl Salicylate, 5% Capryl Decyl Sour cocoa butter was stirred and mixed at a stirring speed of 500 rpm for 20 min in a water bath at 75°C to obtain a uniform oil phase;

[0070] Mix 0.1% Ophiopogon japonicus polysaccharide, 0.6% polyacrylate cross-linked polymer-6, 0.02% carbomer and the rest of water, and stir and mix at a stirring speed of 500 rpm in a water bath at 75°C 20 min to obtain a homogeneous aqueous phase;

[0071] The oil phase is quickly added to the water phase, and sheared at 6000 rpm for 2 min to obtain liquid crystal colostrum;

[0072] Cool the liquid crystal colostrum to 40°C, add 2% p-hydroxyacetophenone and 1.5% 1,2-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com