Part automatic material collecting device in plasma flame cutting platform water tank

A technology of flame cutting and automatic material collection, which is applied in the direction of plasma welding equipment, gas flame welding equipment, manufacturing tools, etc., can solve the problems of difficult and cumbersome parts collection, avoid manual participation in the work of collecting parts, improve collection efficiency, and improve The effect of receiving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

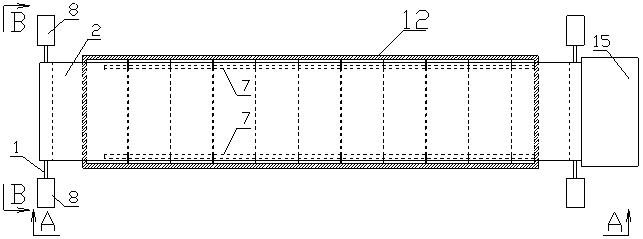

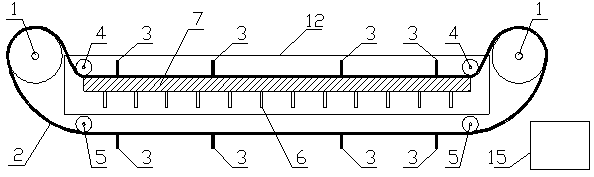

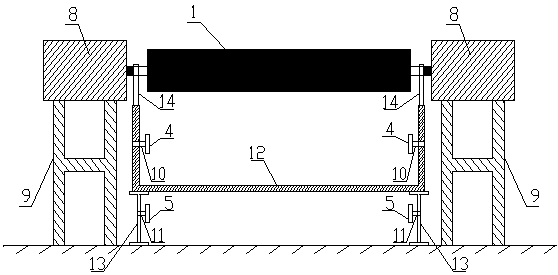

[0027] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as Figure 1-4 shown).

[0028] An automatic receiving device for parts in the plasma flame cutting platform water tank, including a belt conveyor, the water tank 12 is located between the upper and lower conveyor belts 2 of the belt conveyor, and the upper conveyor belt 2 of the belt conveyor passes through the first pressing roller 4 is pressed down to under the water surface in the water tank 12. It also includes a receiving hopper 15, which is located below the tail of the belt conveyor and is used for collecting parts.

[0029] The belt conveyor comprises a pair of main drive rollers 1 and a transmission belt 2, the transmission belt 2 is wrapped around the pair of main drive rollers 1, and the pair of main drive rollers 1 are respectively located at the front and back sides of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com