Automobile housing mould

A shell and mold technology, which is applied to vehicle parts, upper structure, and upper structure sub-assemblies, etc., can solve the problems of unsatisfactory side molding and poor reset mechanism, so as to ensure the side molding effect and prevent top The effect of block breakage, reduced travel distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

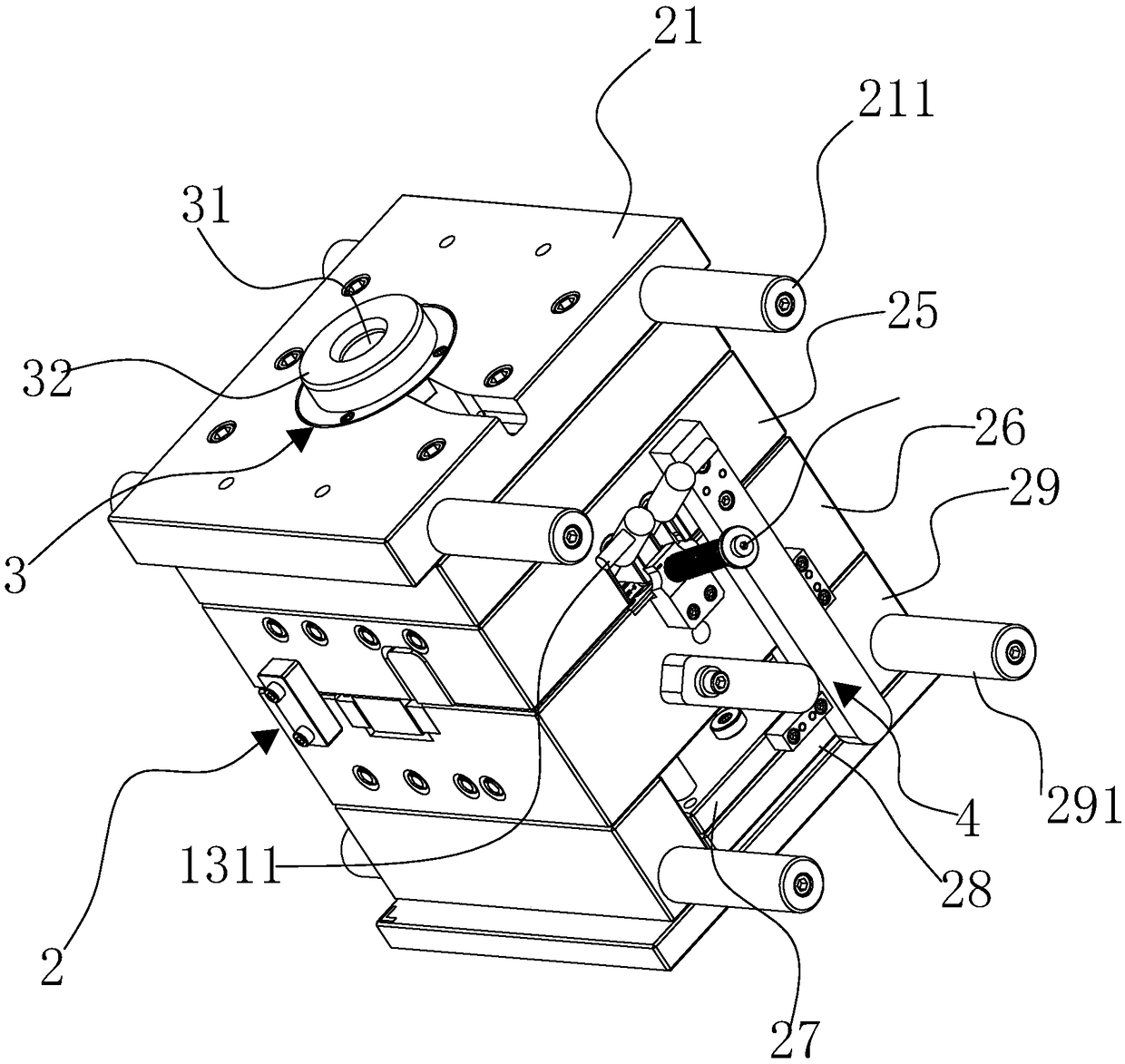

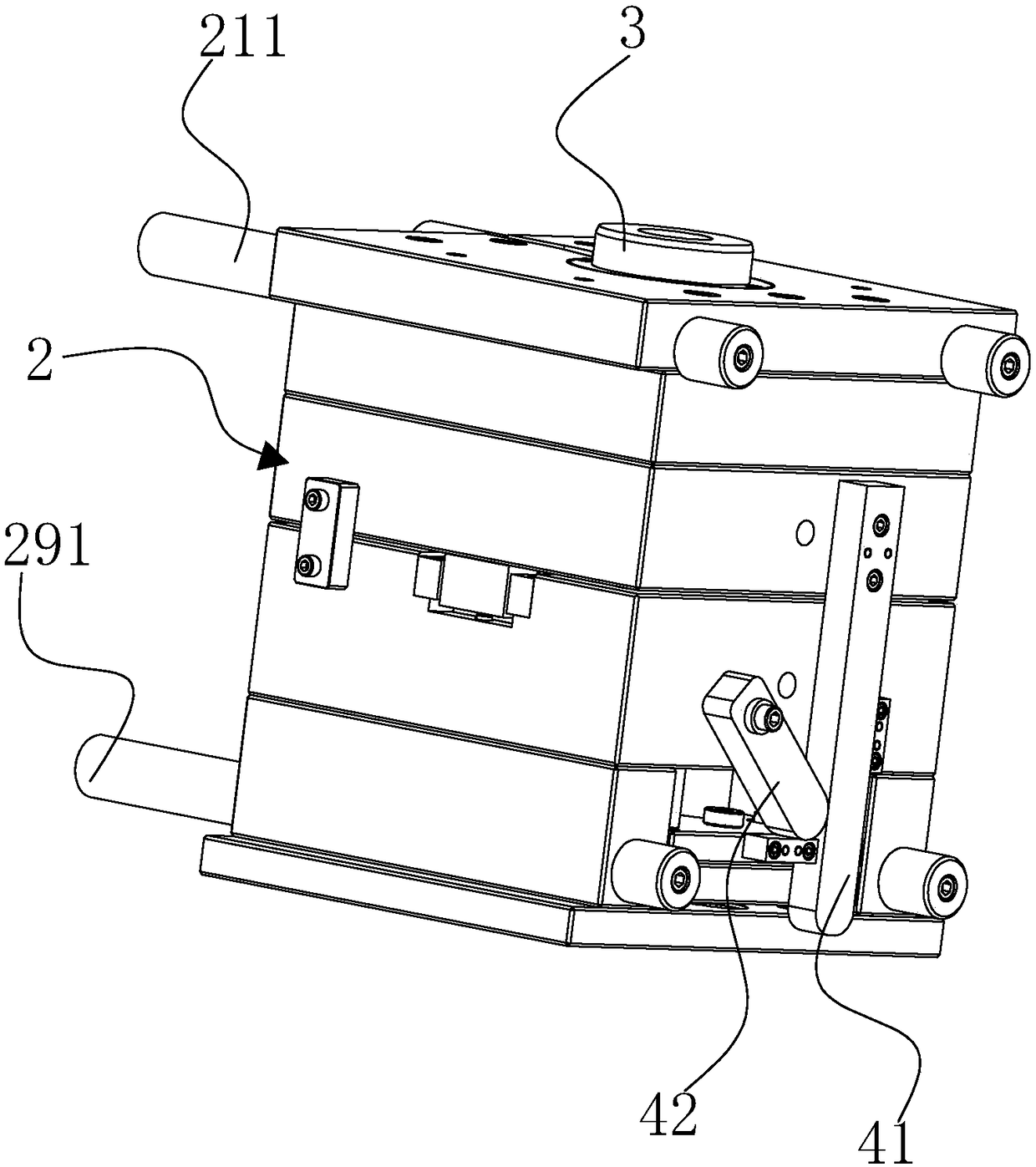

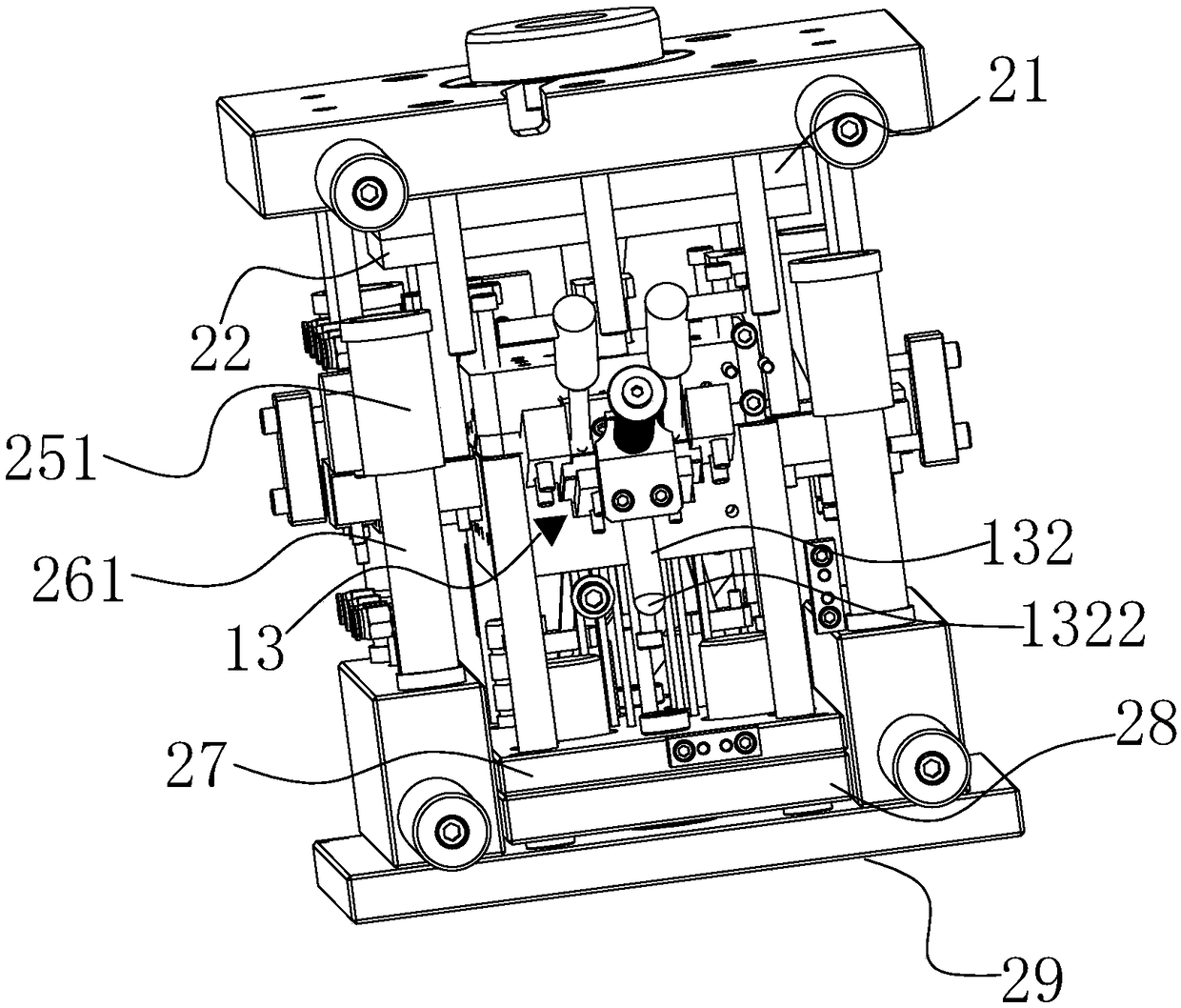

[0034] refer to Figure 1 to Figure 9 , the present embodiment provides an automobile shell mold, comprising:

[0035] Molding device 1, comprises upper mold core 11, lower mold core 12 and lateral forming mechanism 13, upper mold core 11 is placed above lower mold core 12, upper mold core 11 is provided with upper top assembly 111, in lower mold core 12 A lower top assembly 121 is provided, and the lateral forming mechanism 13 includes a plurality of sliders 131, and the sliders 131 are surrounded by the upper mold core 11 and the lower mold core 12 to form a product cavity;

[0036] The formwork device 2 is arranged on the outside of the molding device 1, and is provided with a top plate 21, a first ejector plate 22, a second ejector plate 23, a middle plate 24, an upper template 25, a lower template 26, Ejector panel 27, thimble bottom plate 28, die foot 29;

[0037] The pouring device 3 is provided with a channel 31 for liquid plastic to flow. One end of the channel 31 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com