Outdoor split combined tire for electric locomotive

A technology for combining tires and electric locomotives, applied to road vehicle tires, motor vehicles, road vehicles, etc., can solve problems such as tire leaks, bulges, cracks or missing blocks, personal safety damage to drivers and passengers, and impact on safe driving. Achieve the effect of avoiding personal injury, reducing the risk of vehicle loss of control, and quick and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

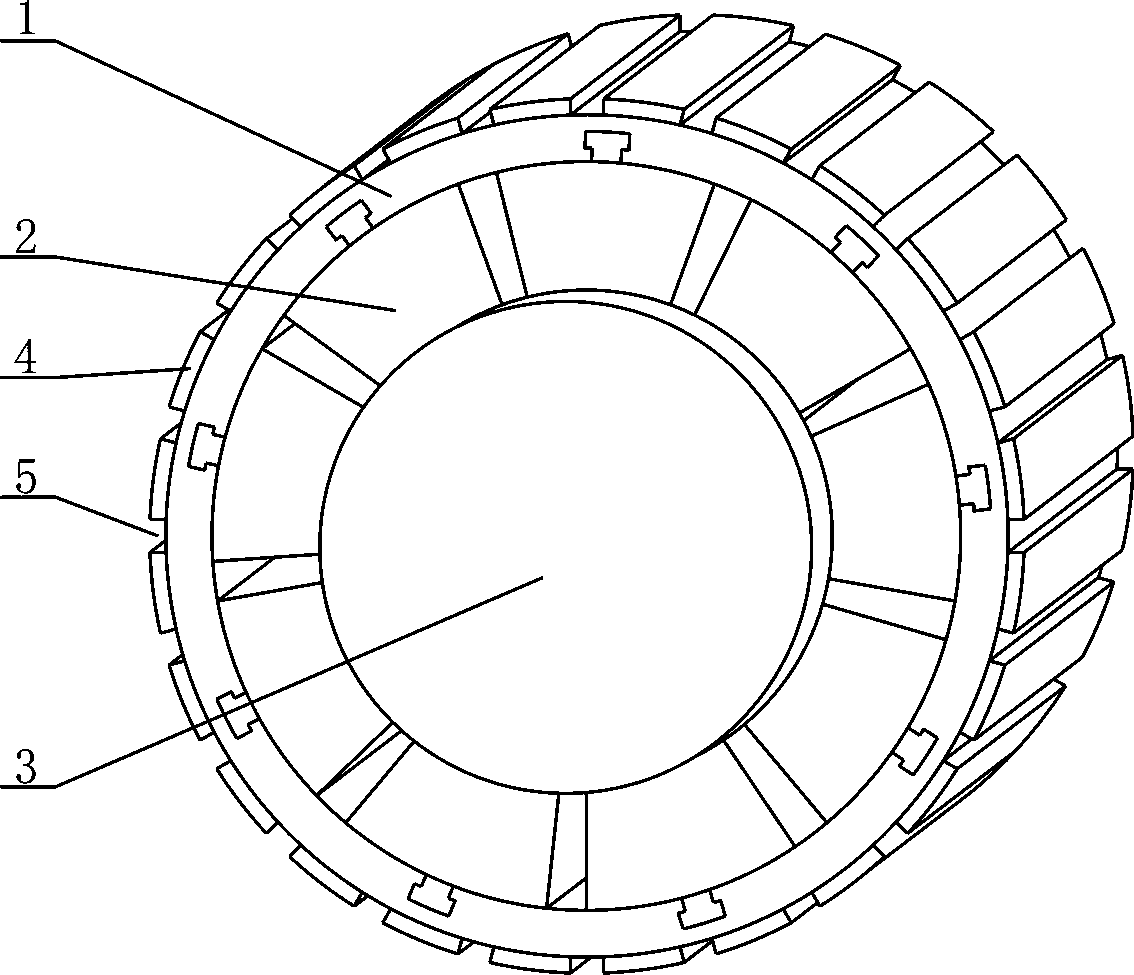

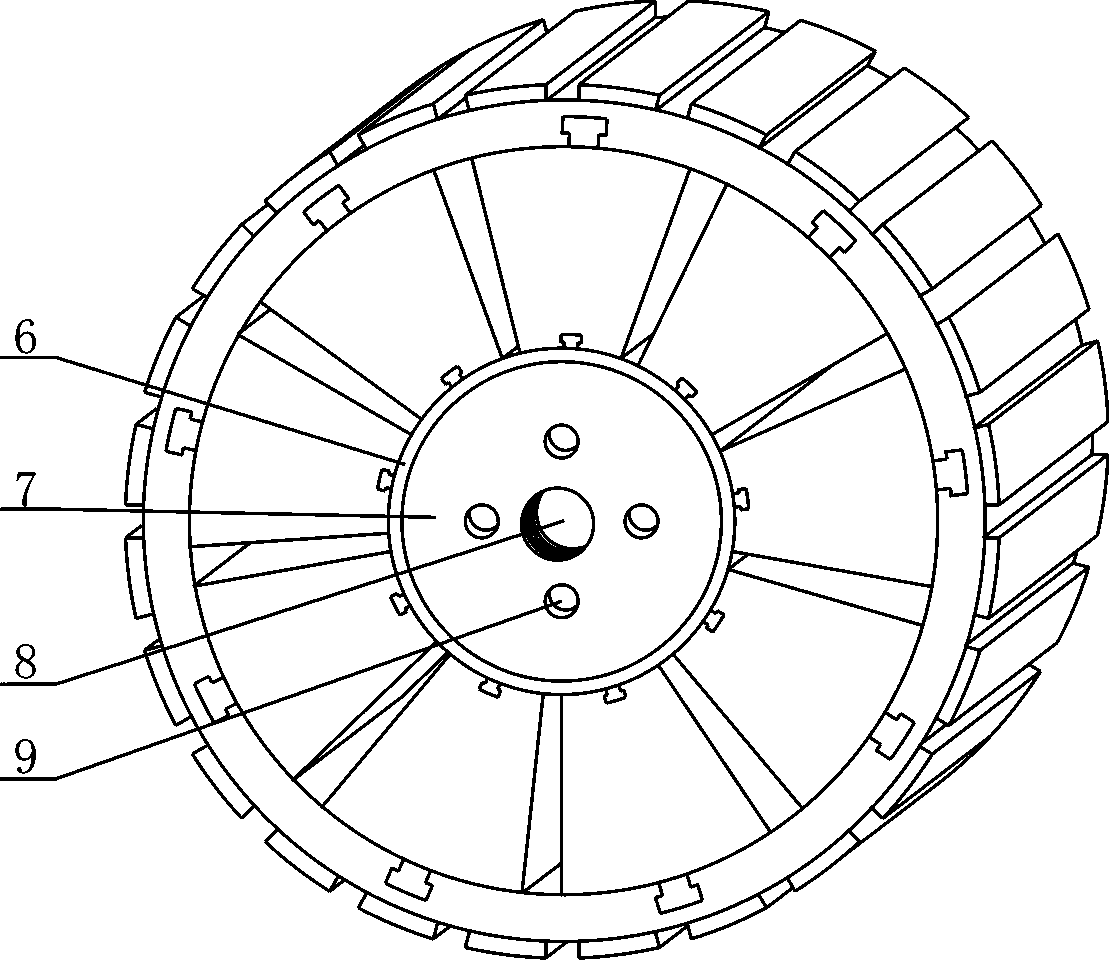

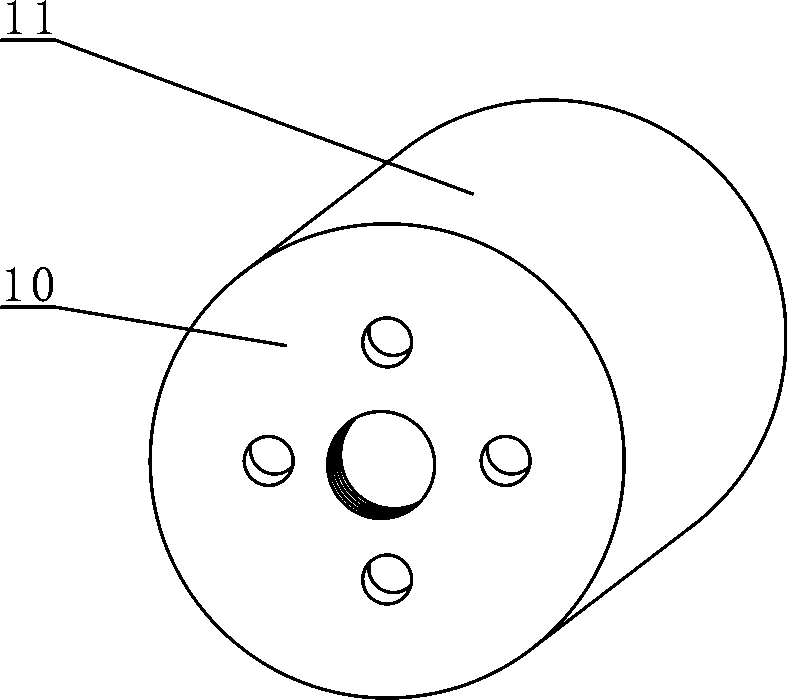

[0027] combined with Figure 1~8 An outdoor split-type combined tire for an electric locomotive, comprising an outer connecting pipe, a fixing block 17, a connecting block 16, an airbag 2, an inner connecting pipe, a sleeve 7 and a fixing device, the outer connecting pipe is provided with a fixing block 17, and the fixing block 17 is provided with connection block 16, and connection block 16 is provided with air bag 2, and air bag 2 is provided with inner connecting pipe, and inner connecting pipe is provided with sleeve 7, and sleeve 7 is provided with fixing device, and outer connecting pipe is provided with by the first A connecting pipe 1 and an anti-slip block 4 are formed. The first connecting pipe 1 is provided with an anti-slip block 4. The air ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com