Tread pattern of bicycle tire

A tread pattern and bicycle technology, applied in the field of tread pattern, can solve the problems such as the negative impact of tire weight reduction, the inability to fully grip the road, and insufficient cornering grip, so as to improve cornering support and force return Elasticity, reducing rigidity difference, and reducing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

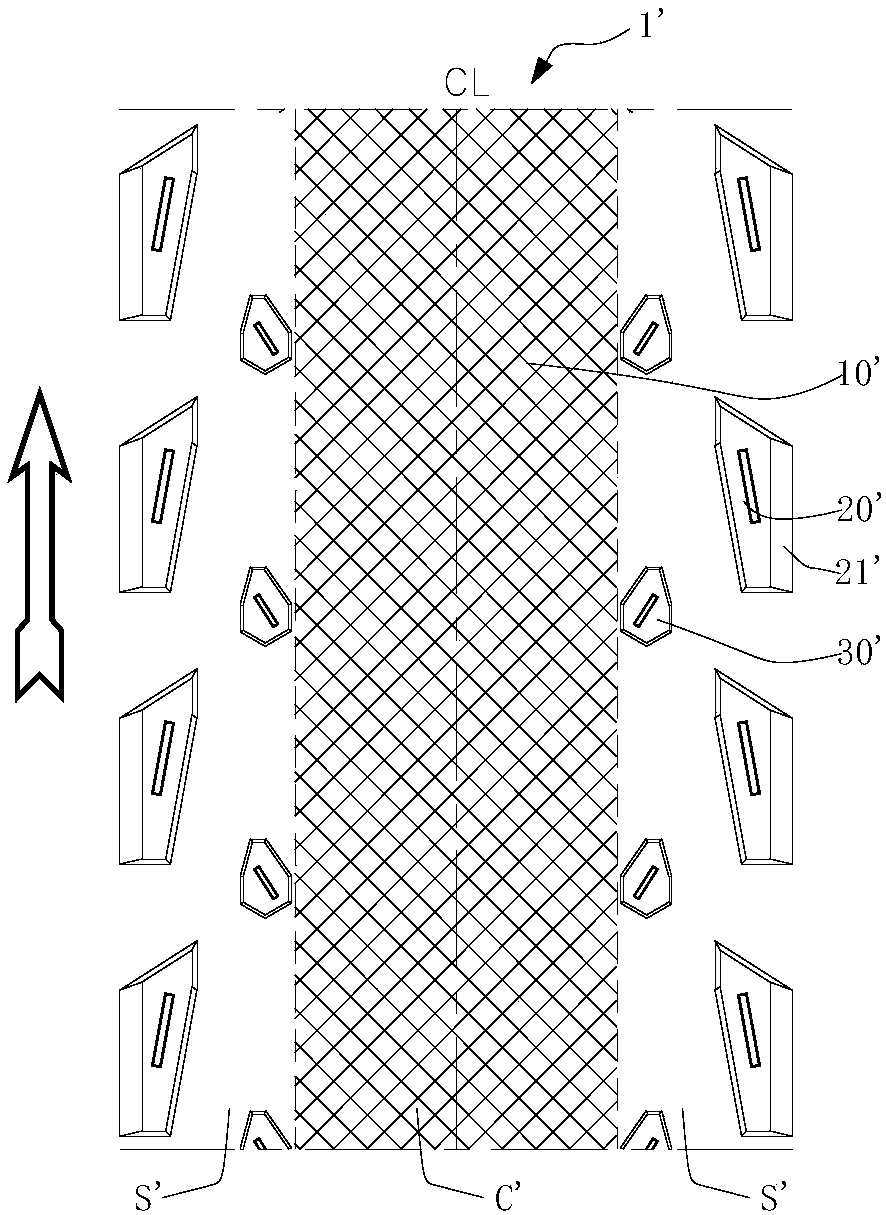

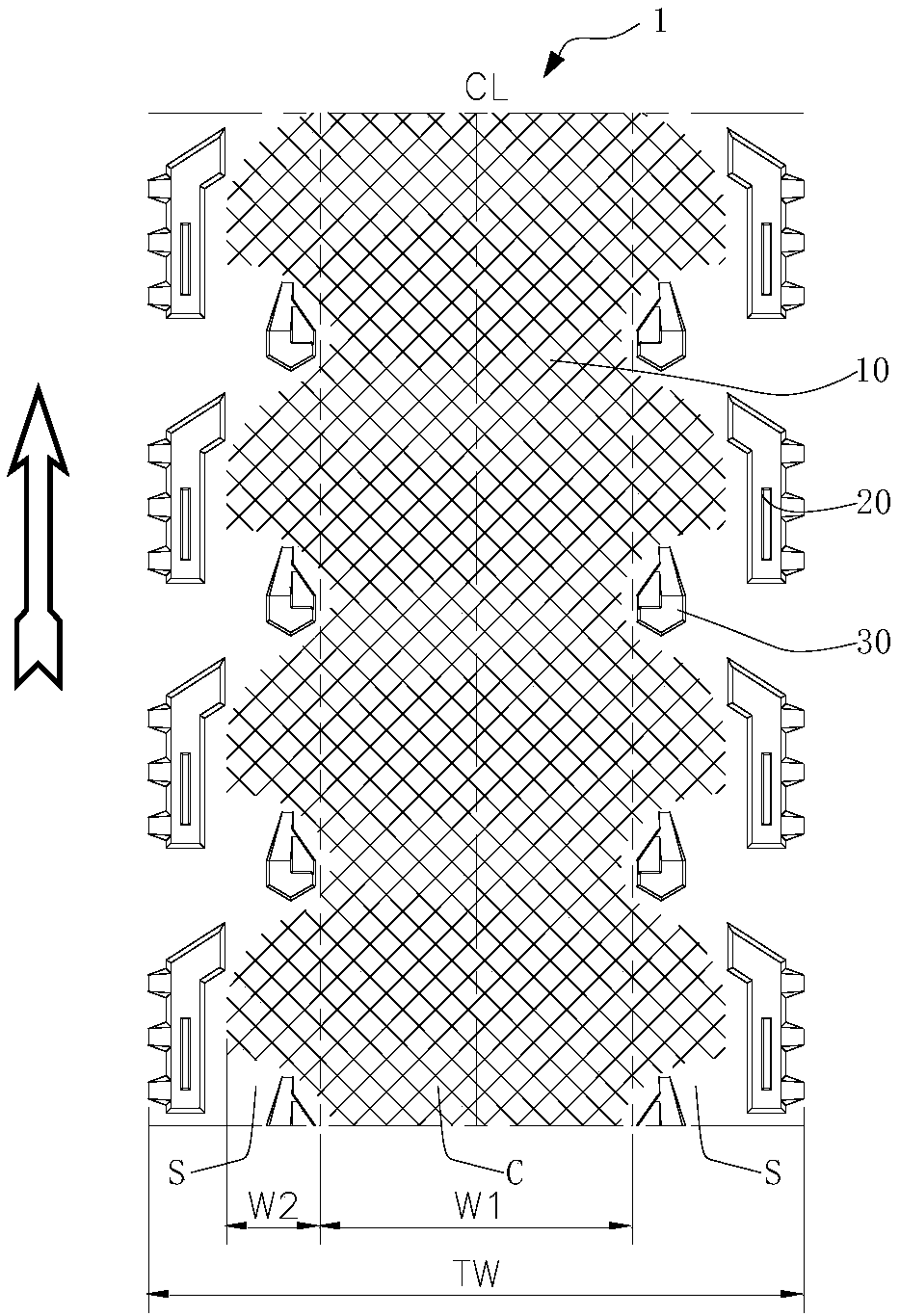

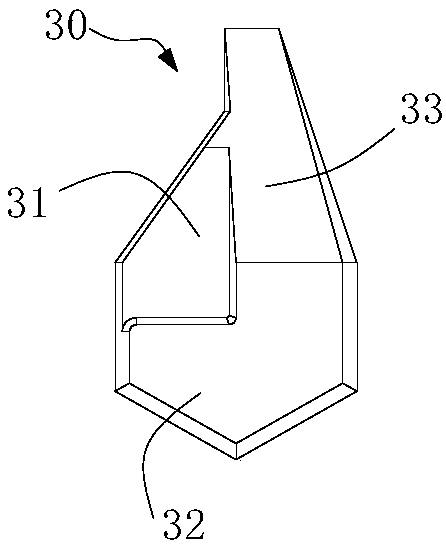

[0040] Such as Figure 2 to Figure 10 As shown, the present invention discloses a bicycle tire tread pattern. exist figure 2 In , the vertical direction is set as the tire circumferential direction, the lateral direction is set as the tire axial direction, CL represents the centerline of the tread, and the arrow points to the tire rolling direction. The front and rear of the present invention are defined according to the rolling direction of the tire, and the first ground contact end is defined as the front end, and the rear ground contact end is defined as the rear end.

[0041] Such as figure 2 As shown, the tread 1 includes a central region C and side regions S located on both sides of the central region C, the central region C ( figure 2 The region defined between the two dotted lines) is symmetrical to the tread centerline CL, and its expanded width W1 is 50%-65% of the total tread expanded width TW. Fine patterns 10 are arranged in the central area C, and irregula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com