Tire curing mold, tire manufacturing method, and pneumatic tire

A tire vulcanization mold and tire technology, applied in the direction of pneumatic tires, tire parts, tires, etc., can solve the problems of partial wear, uniformity deterioration, etc., and achieve the effect of reducing poor rigidity, reducing rigidity, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described with reference to the drawings.

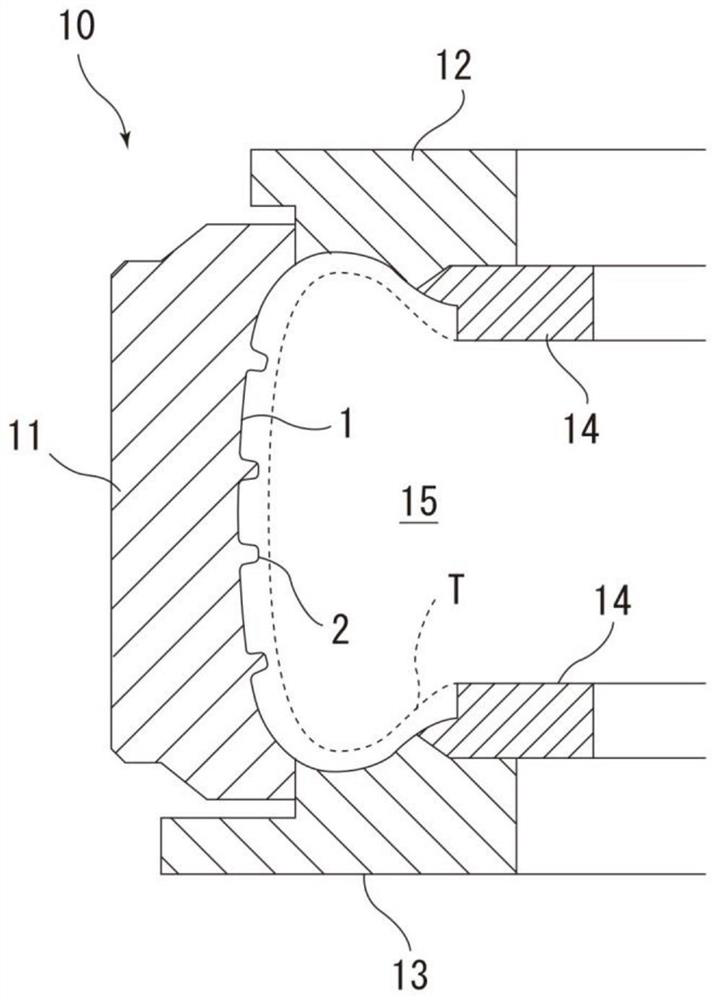

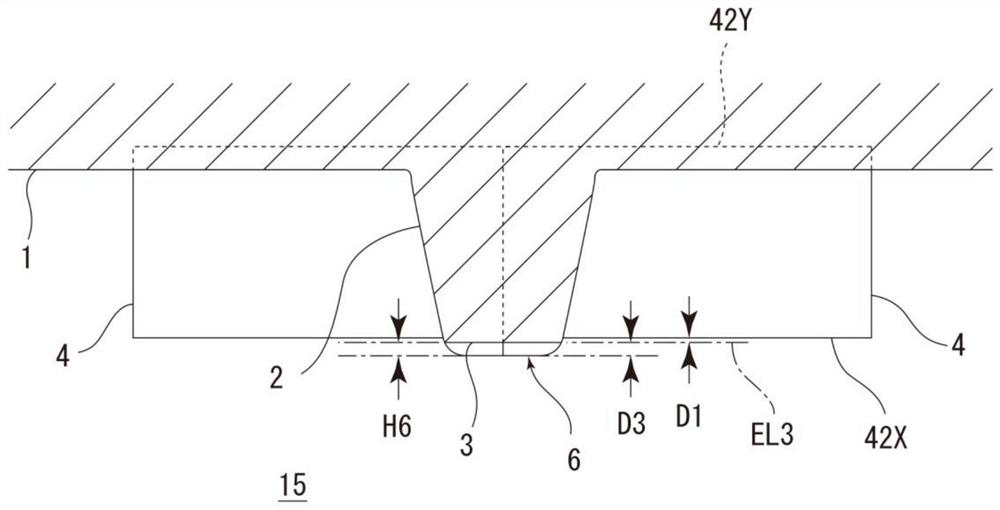

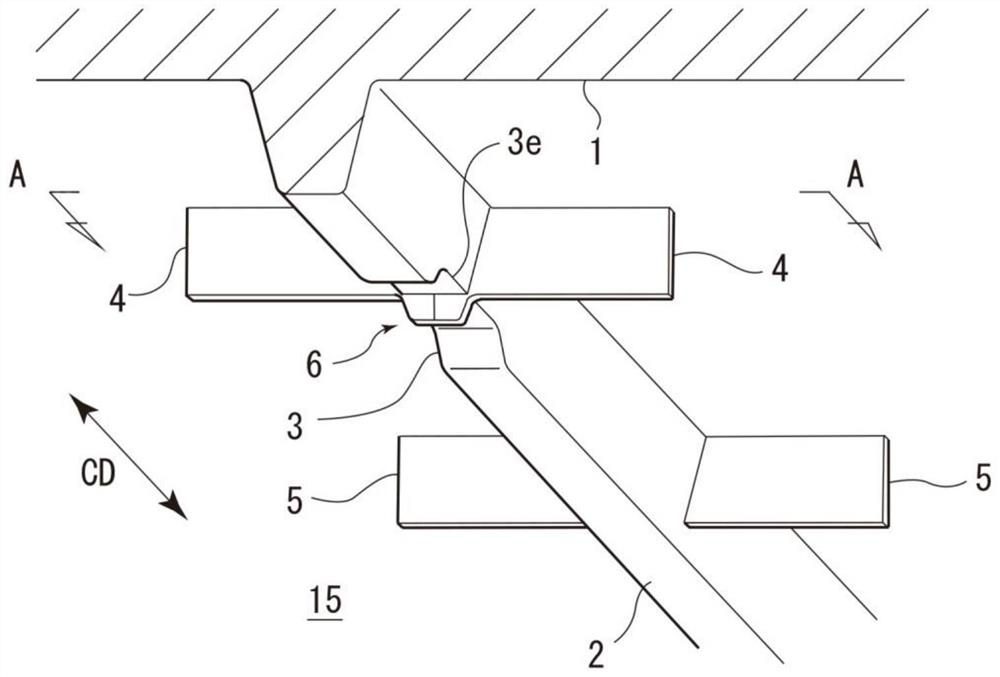

[0030] figure 1 A cross section of the tire vulcanizing mold 10 taken along the tire meridian is shown, and the tire vulcanizing mold 10 is in a closed state. The tire T is installed with the tire width direction facing up and down. exist figure 1 In the figure, the left direction is outside in the tire radial direction, and the right direction is inside in the tire radial direction. figure 2 Zoom in figure 1 The main part of the equivalent along the image 3 A-A to view the section. exist figure 2 , image 3 Herein, the upper direction is the outer side in the tire radial direction, and the lower direction is the inner side in the tire radial direction.

[0031] Such as Figure 1~3 As shown, the tire vulcanization mold 10 has: a tread molding surface 1 which is in contact with the tread of a tire T provided in a cavity 15; a protrusion; and a groove 3 for tread wear ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com