Elastomer internal flow circling structure constant pressure centrifugal pump

A technology of constant pressure and elastic body, which is applied in the field of pump body and constant pressure centrifugal pump with internal flow swirling structure, can solve the problems of unstable delivery pressure of centrifugal pumps, failure to meet the requirements of ceramic powder delivery, wear of metal impellers, etc., to achieve The effect of improving water conservancy efficiency, high water conservancy efficiency, and stable delivery pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

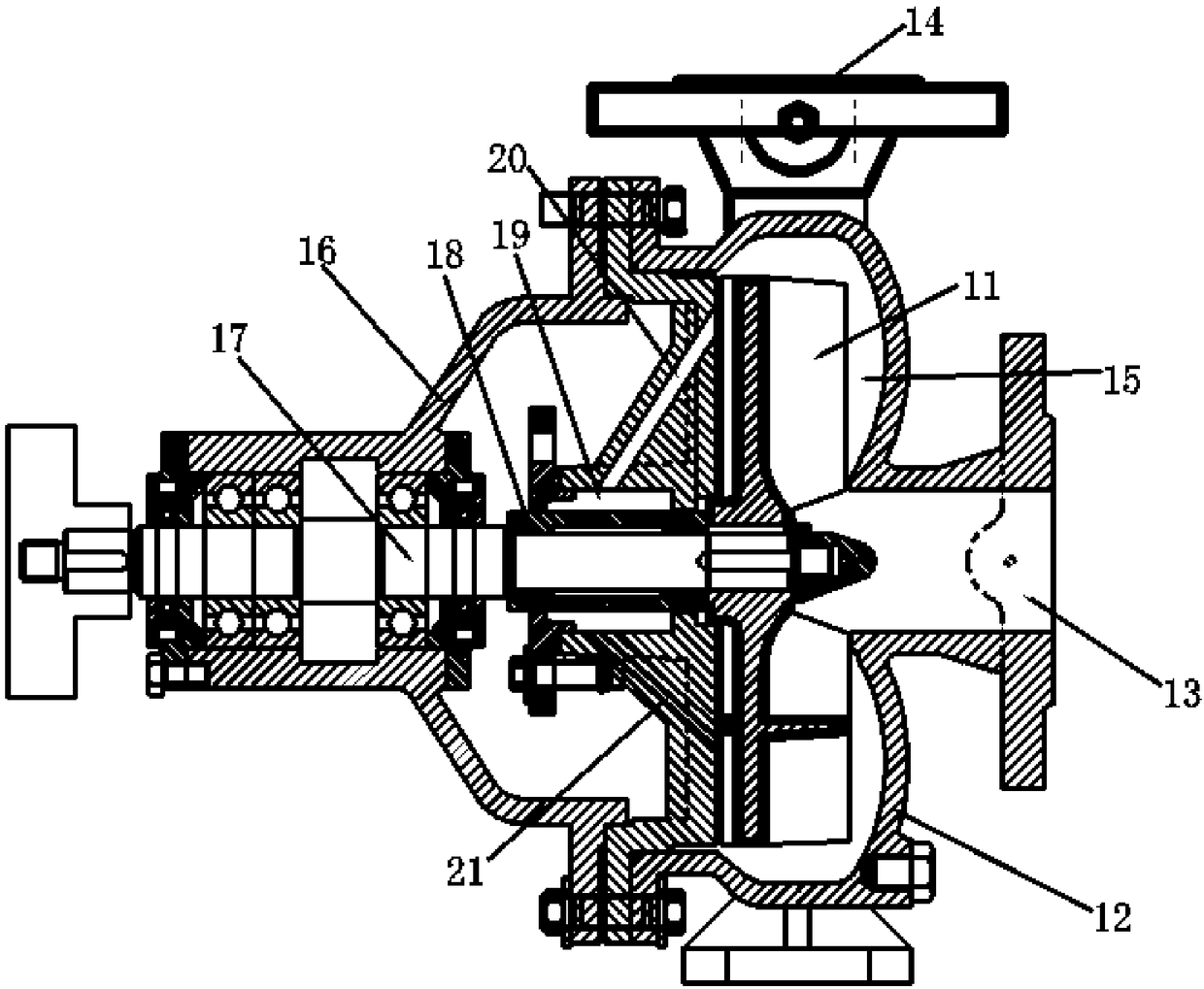

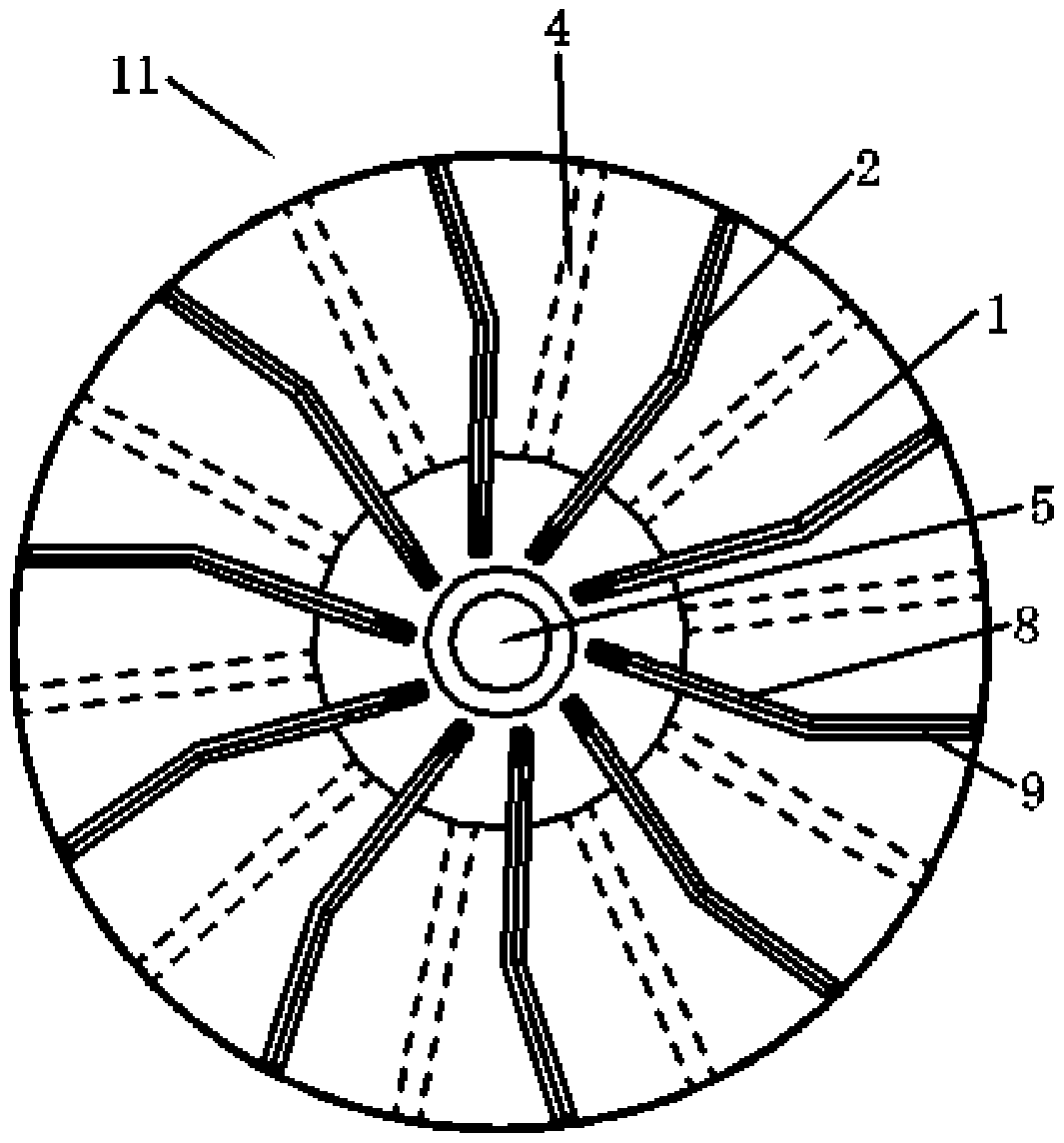

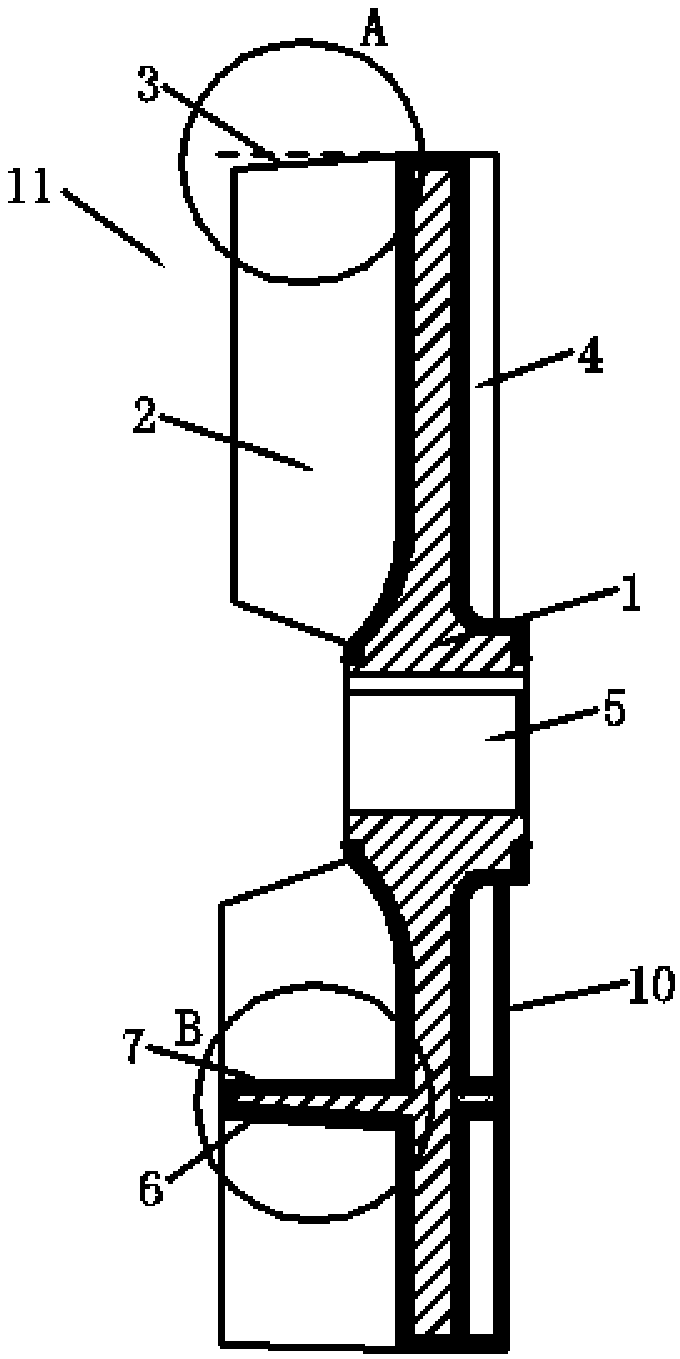

[0018] refer to Figure 1-Figure 6 , the present invention is a constant pressure centrifugal pump with an elastic internal flow swirling structure, including a main body 1, a main vane 2, an auxiliary vane 4, a rubber body 10, a front housing 12 and a rear housing 16, and one side of the main body 1 is provided with several main pumps. Blades 2, the other side of the main body 1 is provided with several auxiliary blades 4, the main blade 2 is formed by connecting the first straight blade 8 and the second straight blade 9, the first straight blade 8 and the second straight blade 9 form a Angle α, the angle range of α is 25°-35°, the ratio of the length of the first straight blade 8 to the length of the second straight blade 9 is 0.68-1, the outer edge 3 of the second straight blade 9 is a sloped side wall, the main body 1. The outer edge is a straight side wall. The angle between the edge of the second straight blade 9 and the outer edge of the main body 1 is β, which is 1.5°-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com