Material pulling device with left-right position capable of being adjusted for printing machine

A limit device, left and right technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of inability to fine-tune left and right, influence of adapting range, and complex pulling material structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

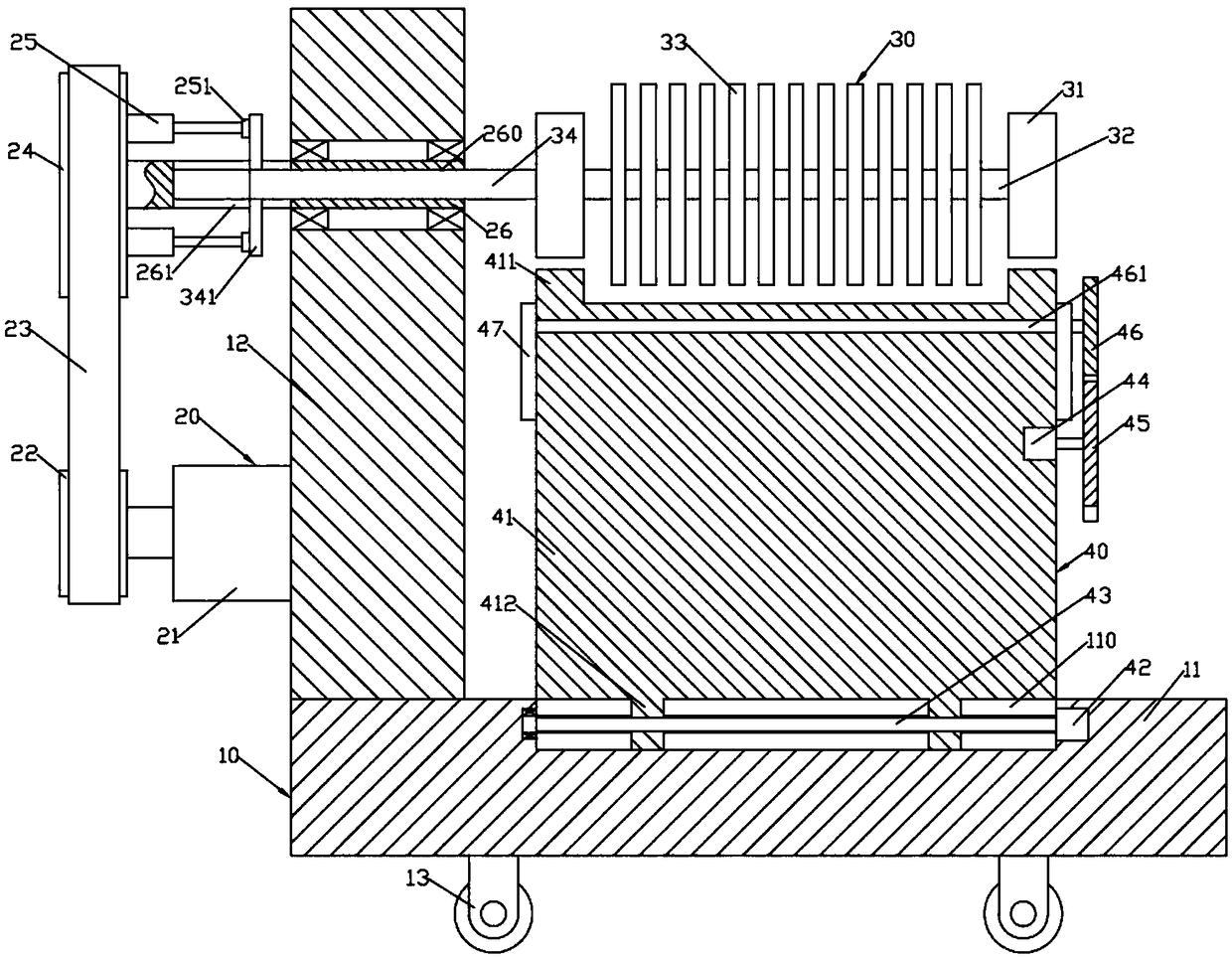

[0014] like figure 1 As shown, a material pulling device with adjustable left and right positions of a printing machine includes a bracket 10, a rotary drive device 20, a sawtooth bar 30 and a workbench unit 40; the bracket 10 includes a support base 11; the left end of the upper end surface of the support base 11 is formed with The left support plate 12; the workbench unit 40 includes a workbench body 41; the workbench body 41 moves left and right and is arranged on the right part of the upper end surface of the support base 11; The left and right ends of 461 are respectively fixed with limiting plates 47; the sawtooth bar 30 is located directly above the workbench body 41; the sawtooth bar 30 includes a central connecting column 32; the left and right ends of the central connecting column 32 are fixed with end plates 31; the central connecting column 32 is evenly formed with a number of disc-shaped sawtooth discs 33; the end faces of a pair of limit plates 47 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com