Secondary lining trolley for rapidly pouring tunnel

A technology for lining trolleys and trolleys, applied in the field of secondary lining trolleys, can solve the problems of unreliable reinforcement of end formwork wood molds, inconvenient removal and installation of waterstops, longer pouring time, etc., so as to improve the appearance quality, The effect of reducing the construction process and high transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

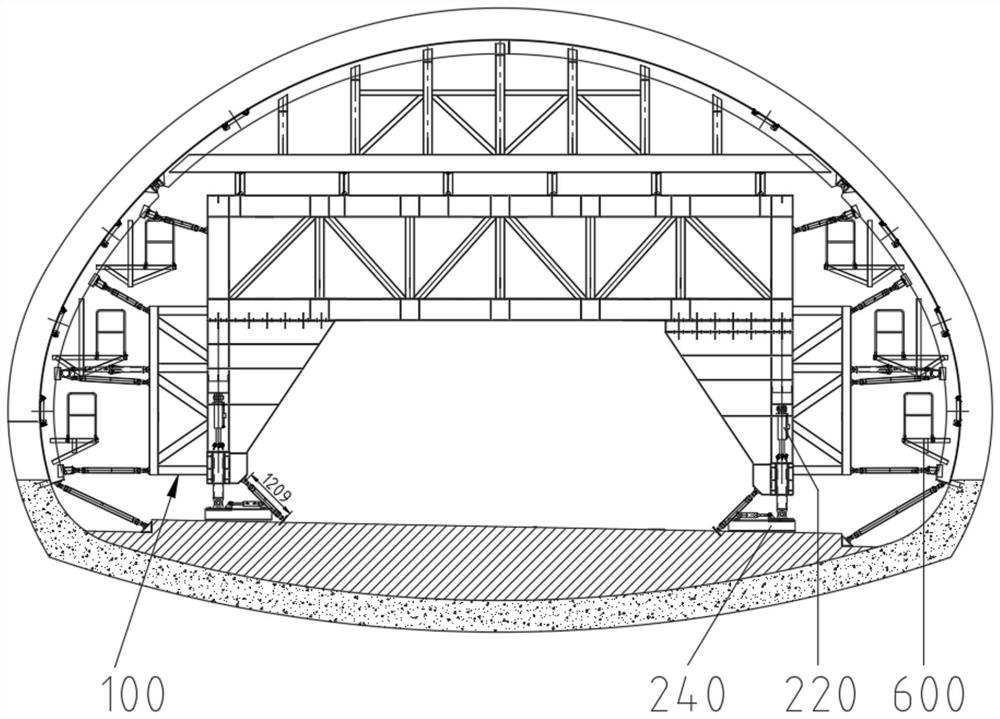

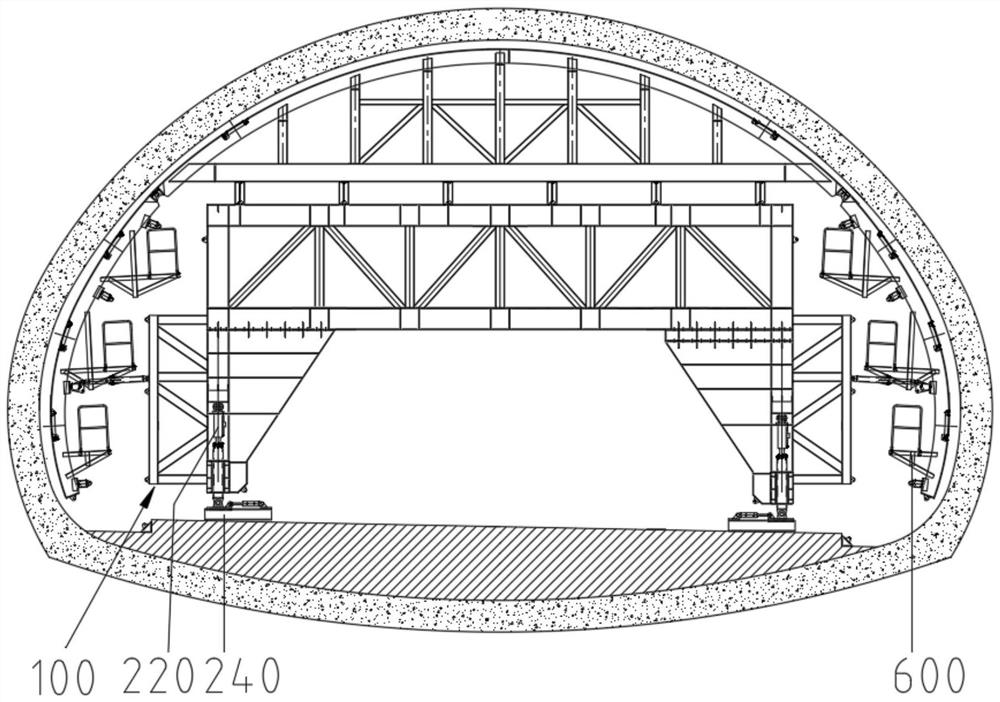

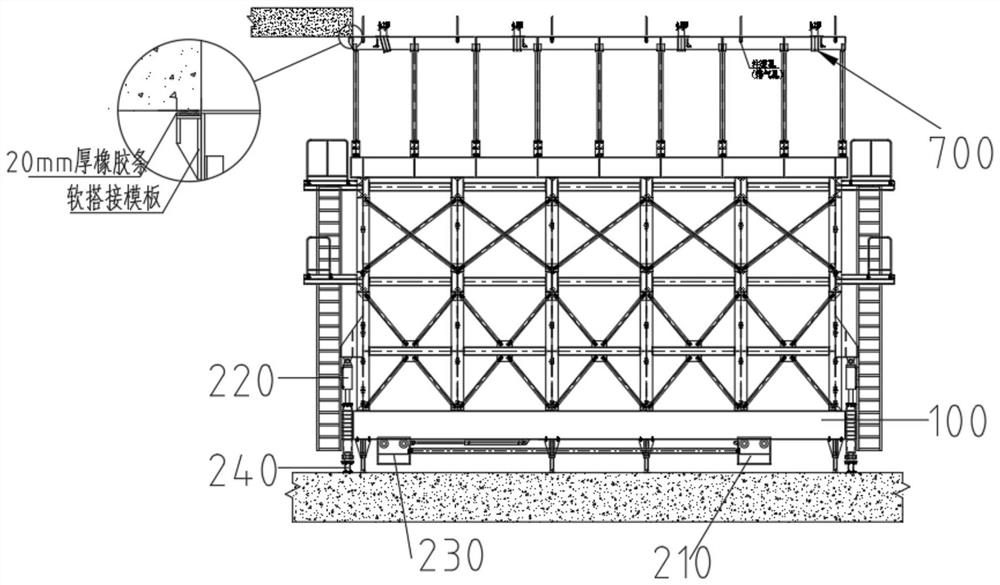

[0063] see Figure 1-Figure 10 :

[0064] The trolley frame 100 is fitted with a primary lining support arch at the top;

[0065] The trackless traveling assembly 200 is installed under the trolley frame 100;

[0066] The telescopic steel end form 300, one end of the trolley frame 100 is installed and connected by a soft lap, the other end is provided with a telescopic steel end form 300, and the telescopic steel end form 300 is connected to the trolley frame 100 through a hinge 310 ;

[0067] The double-pump layer-by-layer full-silo distribution assembly 400 is installed on the trolley frame 100. The discharge ports 470 of the double-pump layer-by-layer full-silo distribution assembly 400 are distributed on both sides of the trolley frame 100. The discharge speed of the discharge port 470 is the same;

[0068] The high-frequency flat vibrator 500 is installed between the discharge ports 470 provided on the trolley frame 100;

[0069] The automatic plug-in vibrating devic...

Embodiment 2

[0073] see again Figure 1-Figure 10 :

[0074] When it is necessary to calculate the safety of the trolley, in order to ensure the pouring volume of 60 cubic meters per hour, the pouring speed and height direction are calculated with the 12-meter trolley, and the average thickness of the surrounding rock is calculated as 0.7m. For the sake of safety, the trolley structure is designed according to the pouring speed of 4m / h, and the check calculation is carried out.

[0075] Load calculation

[0076] Based on the lining thickness of 70cm and the first version of lining of 12m, the amount of concrete poured at one time is 300.6m3.

[0077] (1) Side form load

[0078] Standard value of side mold load:

[0079] The standard value of the pressure of the newly poured concrete on the side of the formwork 720:

[0080] F=0.22×r c ×t 0 ×β 1 ×β 2 ×V 12 =0.22×25×6×1.2×1.15×3 12 =78.9KN / m 2

[0081] F=r c ×H=25×10.8=270KN / m 2

[0082] Take the smaller of the two, so the m...

Embodiment 3

[0116] see again Figure 1-Figure 10 :

[0117] The trackless traveling assembly 200 includes a traveling mechanism 210, a first oil cylinder 220, a second oil cylinder 230 and a support 240. The four first oil cylinders 220 are respectively connected to the front and rear sides of the trolley by bolts. The output end of the first oil cylinder 220 is connected with a support 240 through bolts, and the front end and rear end of the bottom of the trolley are respectively connected with a traveling mechanism 210 and a second oil cylinder 230 through bolts. The output end of the second oil cylinder 230 A running mechanism 210 is connected;

[0118] The single step distance of trackless walking is 1.5 meters. The walking system is equipped with a remote control, which can be operated by a single person to realize the functions of the overall translation, offset, and U-turn of the trolley. The specific working steps are as follows:

[0119] S1, extending the first oil cylinder 220...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com