Highly transparent flame-retardant polyvinyl alcohol film and preparation method thereof

A polyvinyl alcohol film and polyvinyl alcohol technology, applied in the field of polymer chemistry, can solve the problems of reduced flame retardant efficiency, unstable film properties, and easy changes in film properties, achieving high transparency and good wet stability , Excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Take 100.00g of a transparent PVA aqueous solution with a mass percentage concentration of 12%, add 2.10g of a CEP aqueous solution with a mass percentage concentration of 30%, and stir for 1-3 hours to obtain a stable viscous solution with a uniform hue, which is a mixture containing CEP and PVA. Solution, based on the sum of the mass of CEP and PVA in the mixed solution, the mass content of CEP in the mixed solution is 5%. The mixed solution was poured into a glass mold and cast into a film. The film was placed at 30°C for 4 hours to partially volatilize the solvent, and then placed in a vacuum drying oven at 80°C to continue drying to constant weight to obtain a highly transparent flame-retardant PVA film.

Embodiment 2

[0060] Take 100.00g of a transparent PVA aqueous solution with a mass percentage concentration of 12%, add 4.45g of a CEP aqueous solution with a mass percentage concentration of 30%, and stir for 1-3 hours to obtain a stable viscous solution with uniform hue, which is a mixture containing CEP and PVA. The solution is based on the mass sum of CEP and PVA in the mixed solution, and the mass content of CEP in the mixed solution is 10%. The mixed solution was poured into a glass mold and cast into a film. The film was placed at 30°C for 4 hours to partially volatilize the solvent, and then placed in a vacuum drying oven at 80°C to continue drying to constant weight to obtain a highly transparent flame-retardant PVA film.

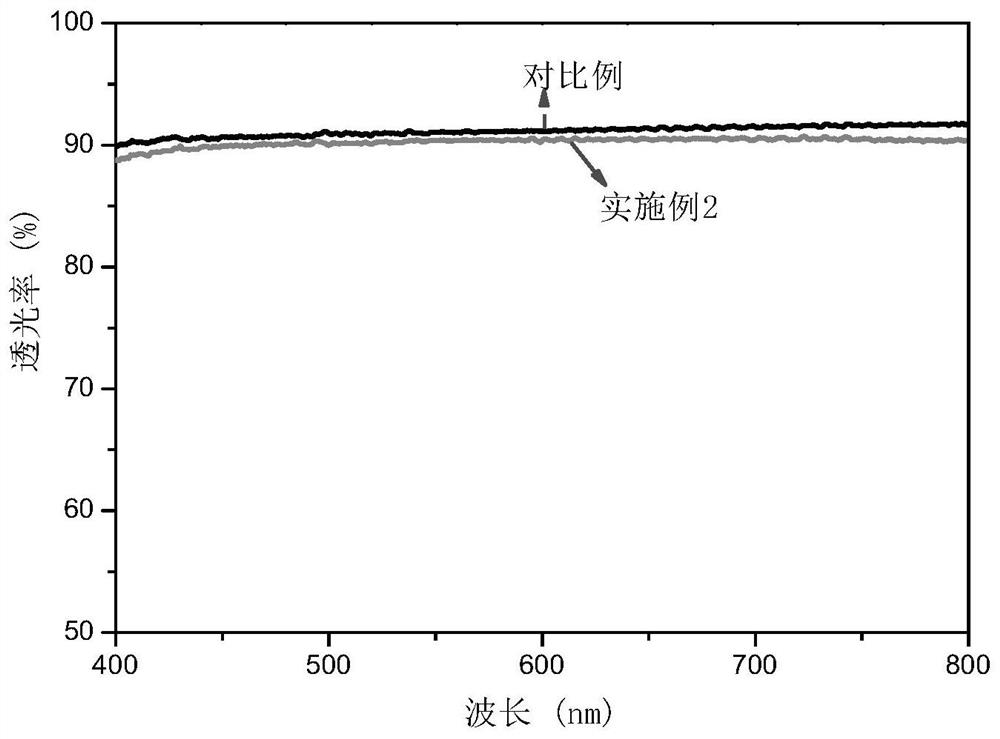

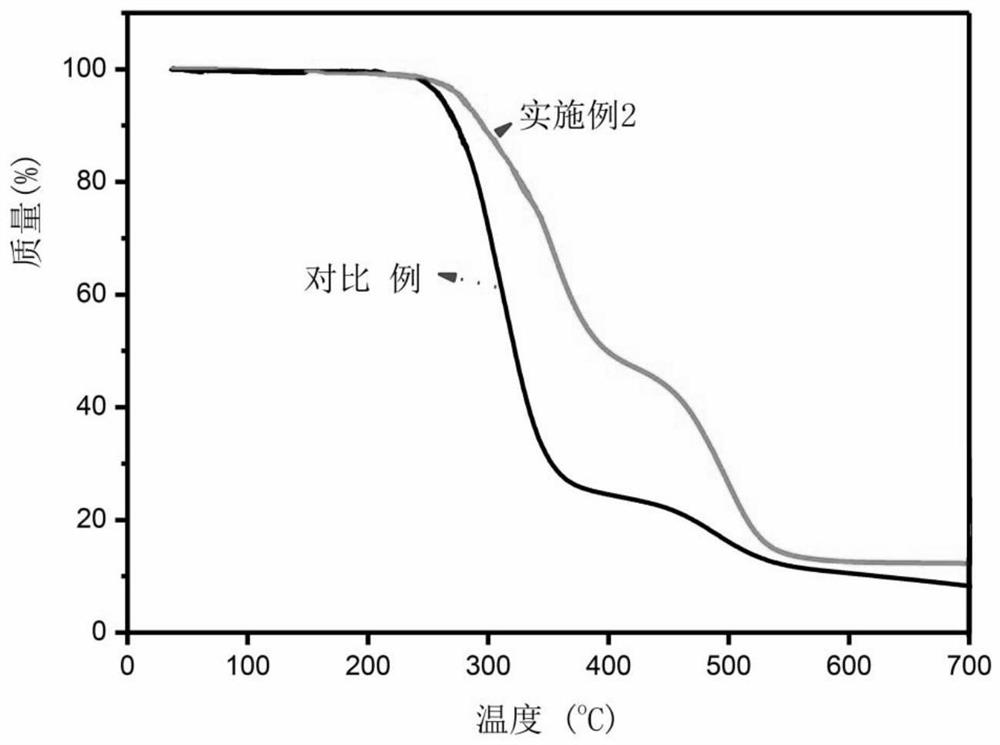

[0061] figure 2 For the light transmittance of comparative example and embodiment 2 gained PVA film, the result shows that in the scope of visible light, the light transmittance of comparative example pure PVA film is 90%, but the composite PVA film (embodime...

Embodiment 3

[0064] Take 100.00g of a transparent PVA aqueous solution with a mass percent concentration of 12%, add 7.06g of a CEP aqueous solution with a mass percent concentration of 30%, and stir for 1-3 hours to obtain a stable viscous solution with a uniform hue, which is a mixture containing CEP and PVA. The solution is based on the mass sum of CEP and PVA in the mixed solution, and the mass content of CEP in the mixed solution is 15%. The mixed solution was poured into a glass mold and cast into a film. The film was placed at 30°C for 4 hours to partially volatilize the solvent, and then placed in a vacuum drying oven at 80°C to continue drying to constant weight to obtain a highly transparent flame-retardant PVA film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com