Transmission mechanism for two-direction automatic variable-speed motor

An automatic speed change and transmission mechanism technology, applied in the mechanical field, can solve the problems of unsmooth reversing, uncontrollable, bumping into the upper end surface of the inner ring, etc., and achieve the effects of smooth switching, improved stability, and improved operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

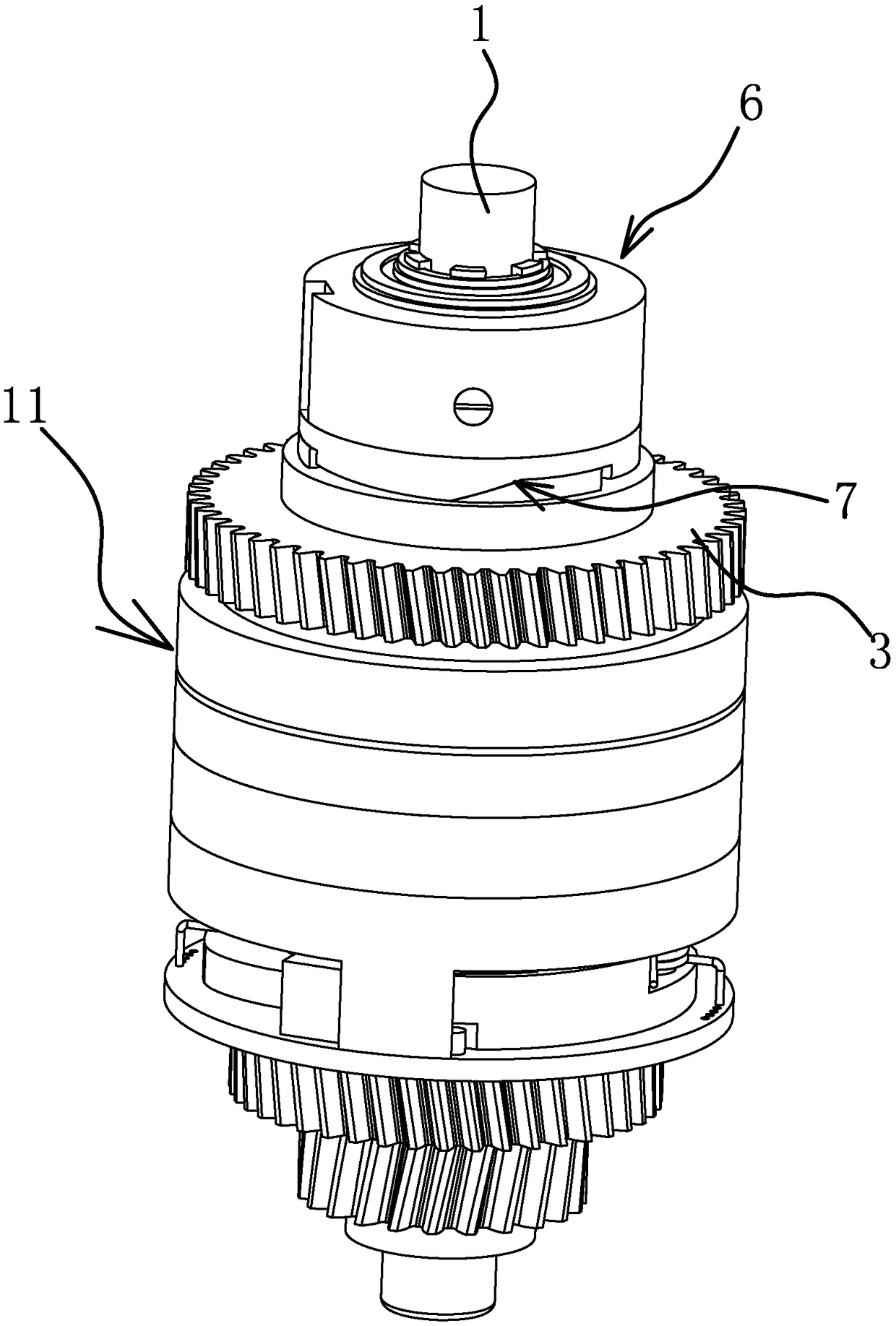

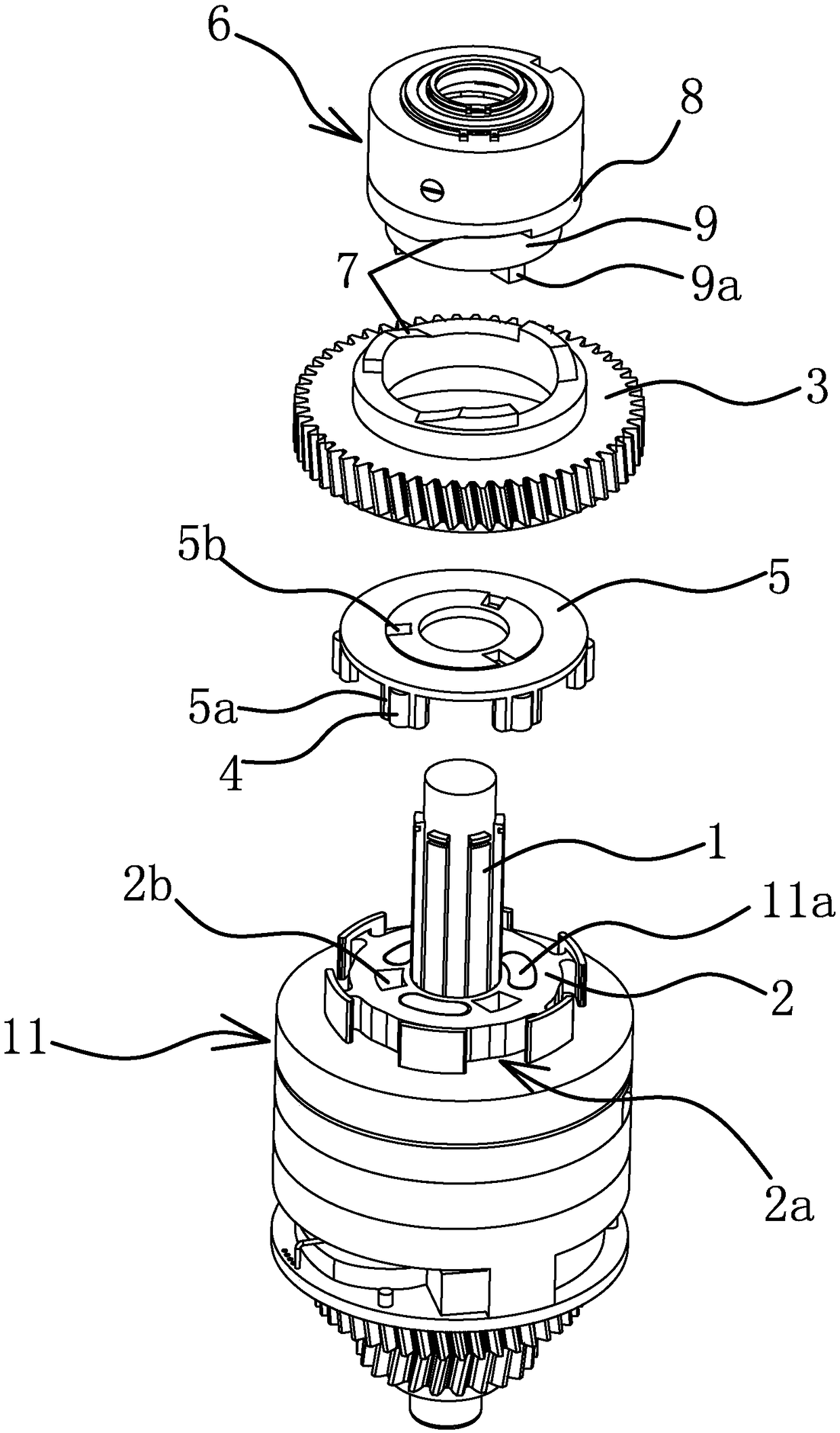

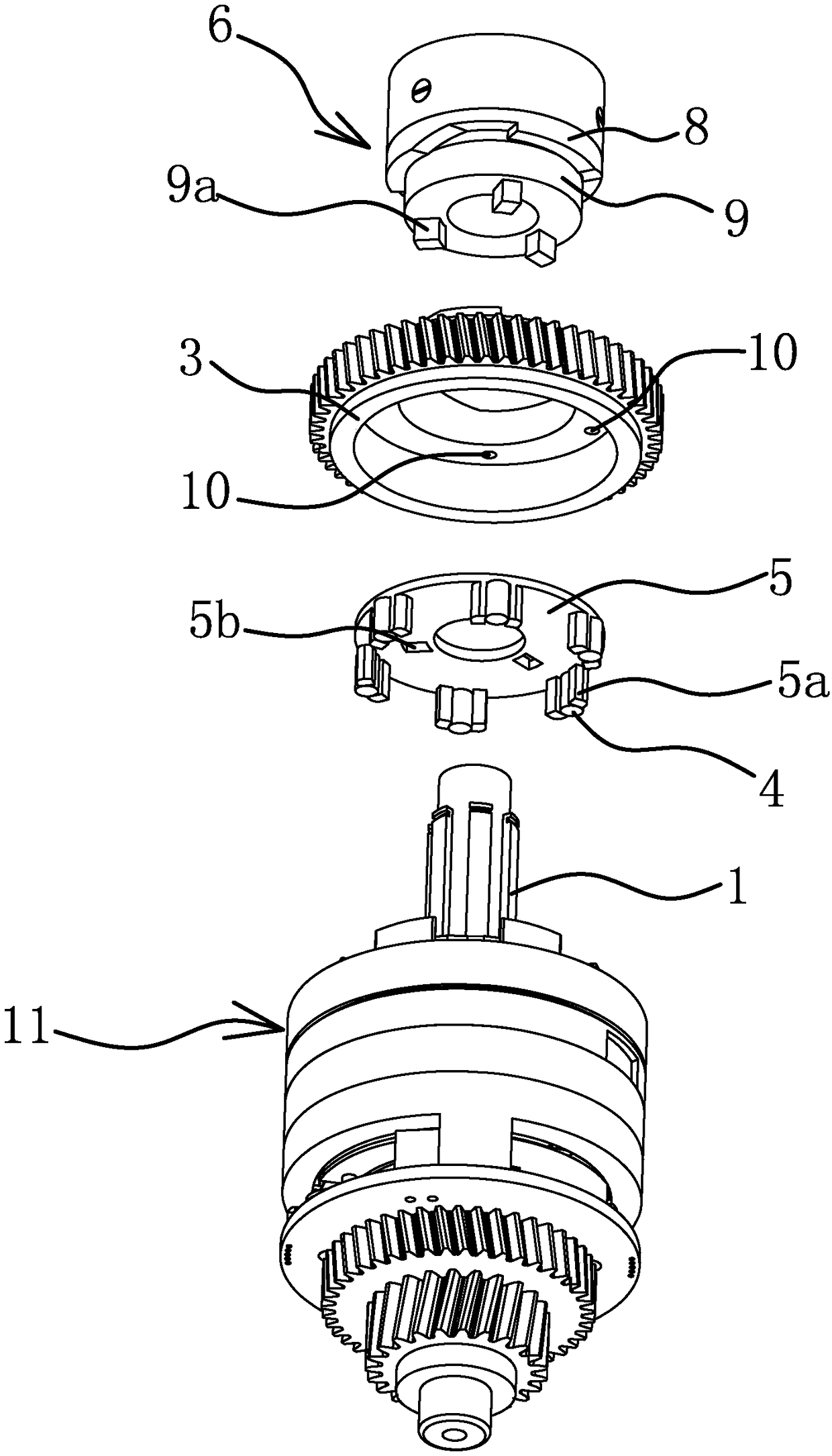

[0038] like figure 1 , figure 2 and image 3 As shown, the transmission mechanism of the two-way automatic variable speed motor includes the main shaft 1 and the inner ring 2 and the coupling sleeve 6 both sleeved on the main shaft 1, the output gear is fixed on the main shaft 1, the inner ring 2 is circular and the inner ring 2 Circumferentially fixed with the main shaft 1, the inner ring 2 is provided with a ring-shaped outer ring 3, and a unidirectional structure is provided between the inner ring 2 and the outer ring 3. The relief grooves 2a and the rollers 4 arranged in each relief groove 2a. When the outer ring 3 is rotated in the reverse direction, there is a disengagement structure 7 that can make the combination sleeve 6 move away from the outer ring 3 between the combination sleeve 6 and the outer ring 3 (the specific structure of the disengagement structure 7 can refer to the application number of 201620877779.X discloses a two-way automatic variable speed motor...

Embodiment 2

[0051] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the joint section 1 2a11 and the joint section 2a12 are two convex arc surfaces located on the same circumference, and the transition section 2a13 is a straight surface connected between the two convex arc surfaces.

Embodiment 3

[0053] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that in this embodiment, the positioning structure includes a number of protrusions arranged on the inner top wall of the outer ring 3 and a number of protrusions arranged on the upper end surface of the coupling plate 5 along the circumferential direction. The shape of the protruding head is the same as that of the groove and the protruding head has elasticity, the number of the protruding heads is less than the number of the grooves, each groove is continuously distributed and there is a circular arc transition between two adjacent grooves.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap