Drop hammer type dynamic biaxial extension test device

A biaxial stretching and testing device technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the increase in device cost and complexity, affecting the accuracy of test results and processing accuracy requirements High and other problems, to achieve the effect of accurate and reliable test data, compact structure and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

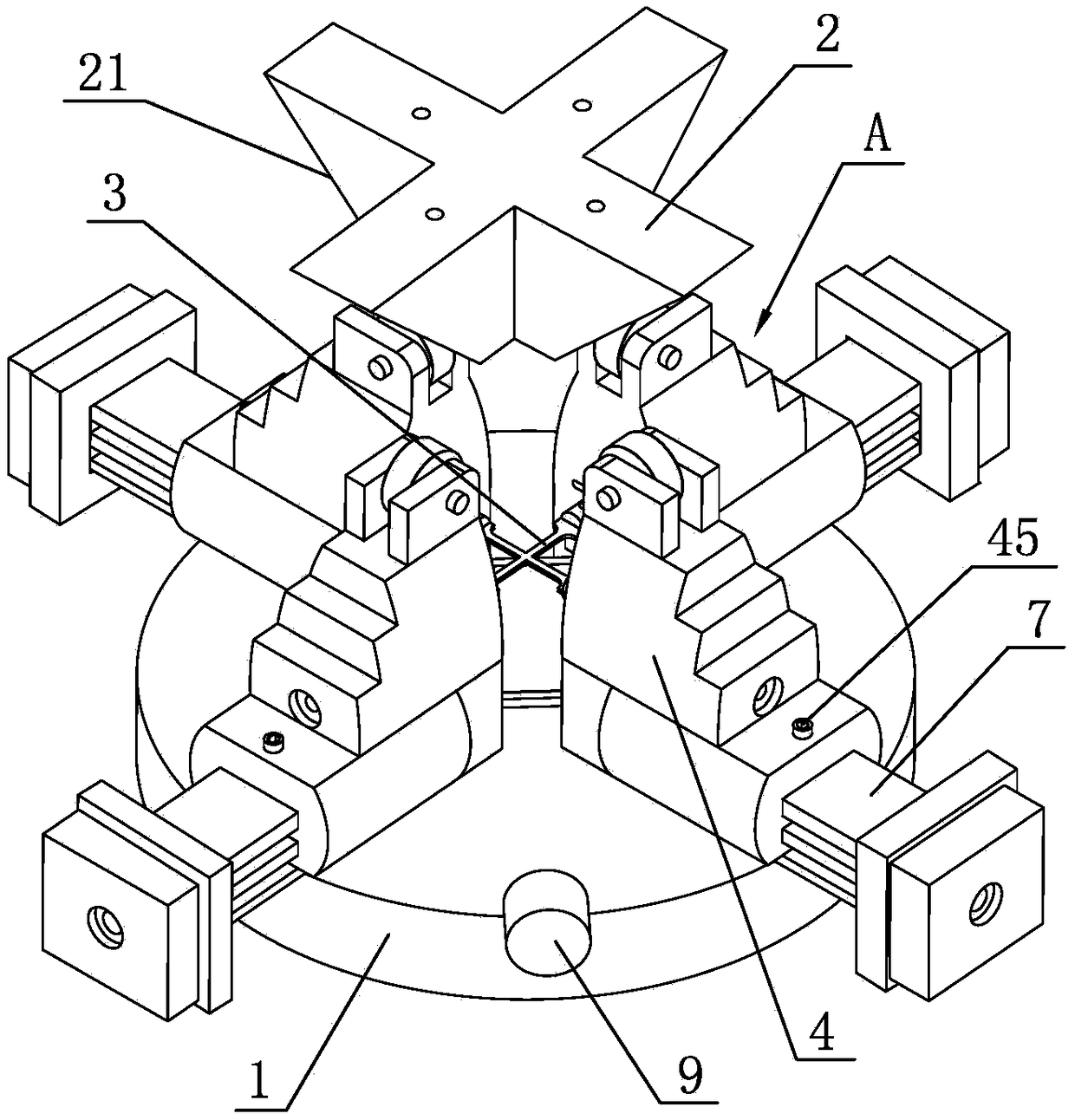

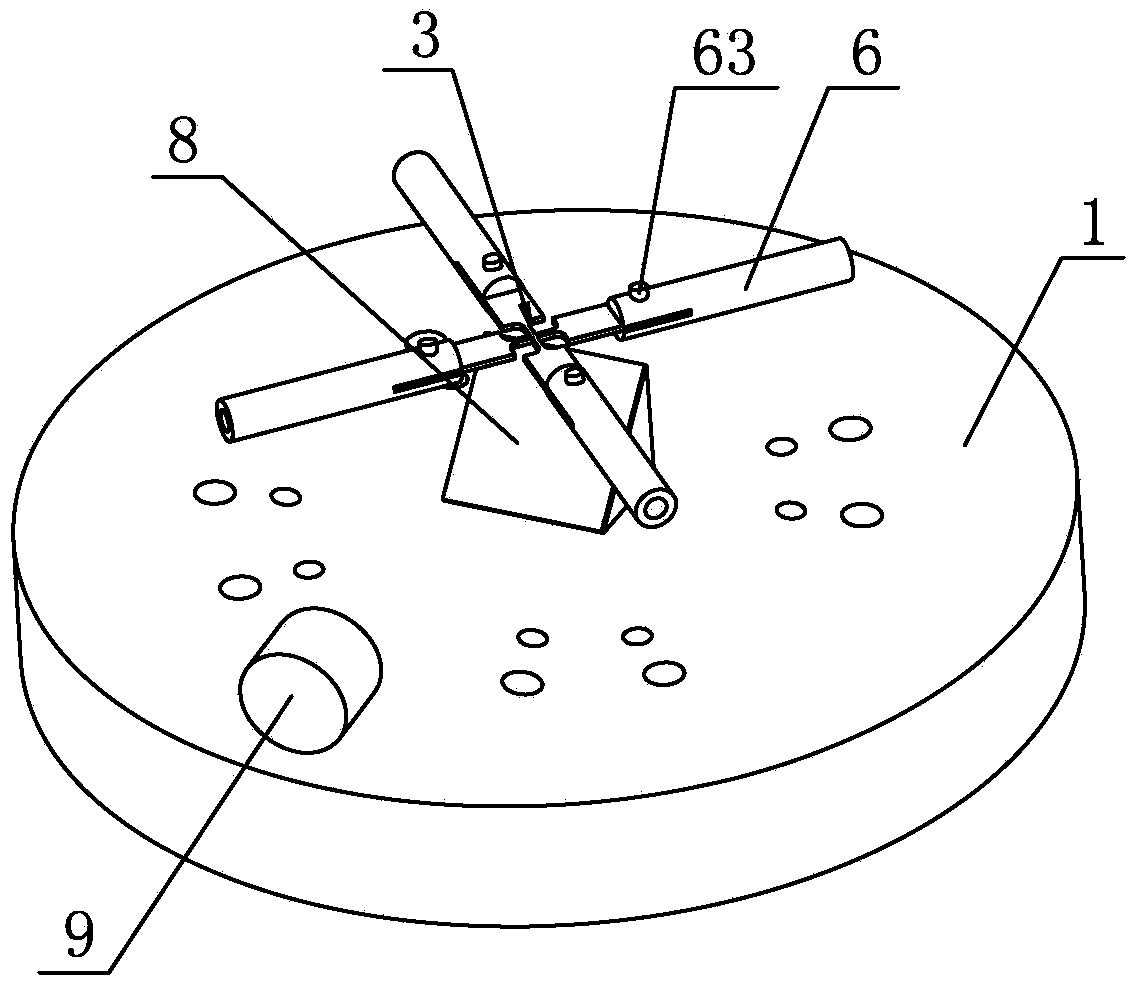

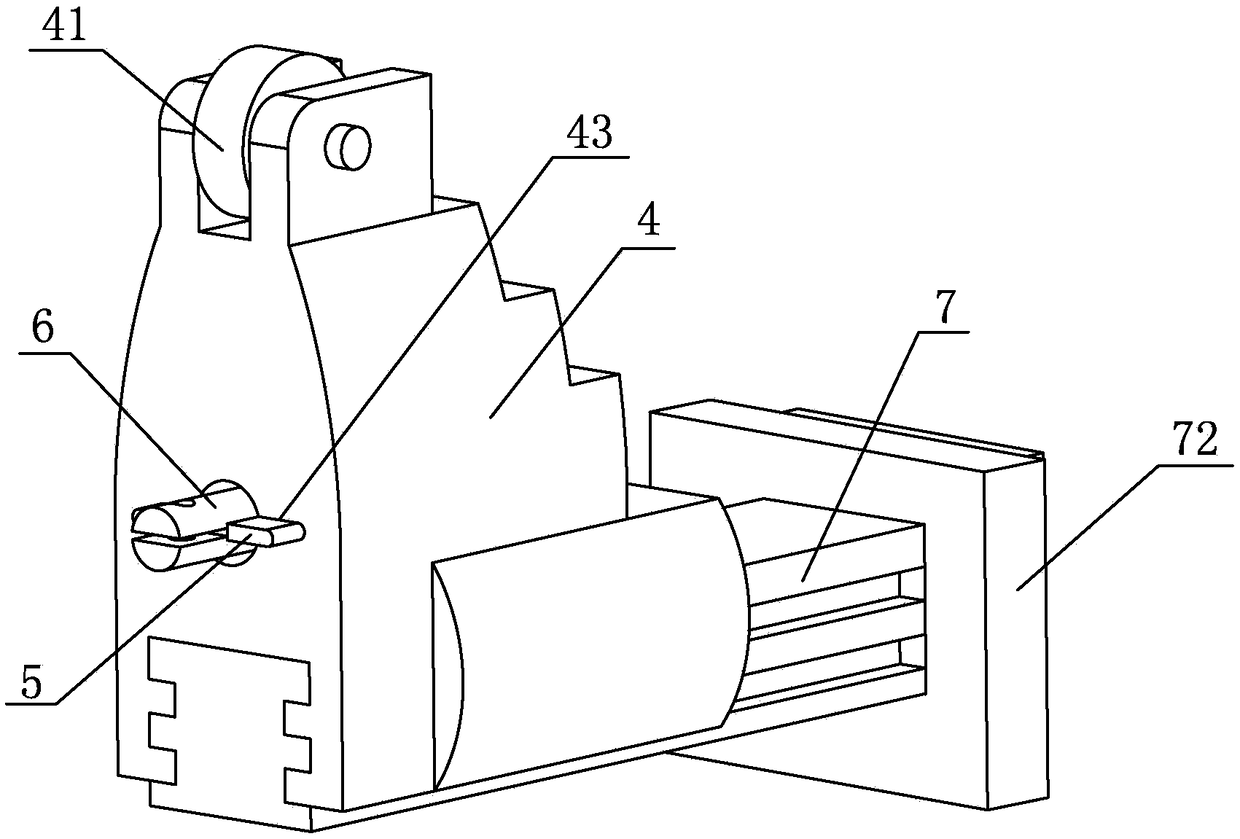

[0020] As shown in the figure, a drop hammer type dynamic biaxial tensile test device includes a chassis 1, a hammer head 2 and four sets of clamping arms 31 for clamping the four tensile arms 31 on the test piece 3 in a one-to-one correspondence. The device A and the clamping device A are arranged opposite to each other, and a sliding device that moves along the length direction of the stretching arm 31 of the test piece 3 is arranged between the clamping device A and the chassis 1. The clamping device A includes a slider 4, The positioning piece 5 and the cylindrical fixture 6, the inner side of the upper end of the slider 4 is hinged with a roller 41, the roller 41 is covered with a rubber ring (not shown in the figure), and the slider 4 is provided with a horizontal fixture installation hole 42, The clamp 6 is arranged in the clamp mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com