Linear Coiled Tube X-ray Flaw Detection Robot for Overhead Transmission Lines

A technology for overhead transmission lines and coiled tubing, applied in the field of flaw detection robots, can solve problems such as inability to hold pipe fittings, unfavorable quick pipe fittings, and clamping detection, etc., to ensure stability, increase the scope of use, and avoid the effects of wind reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

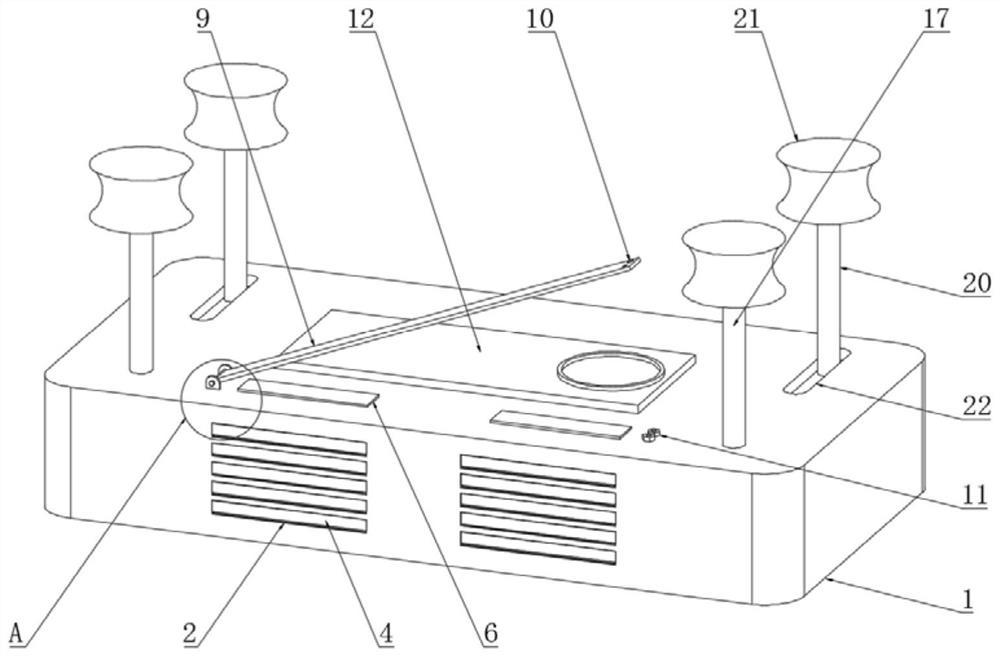

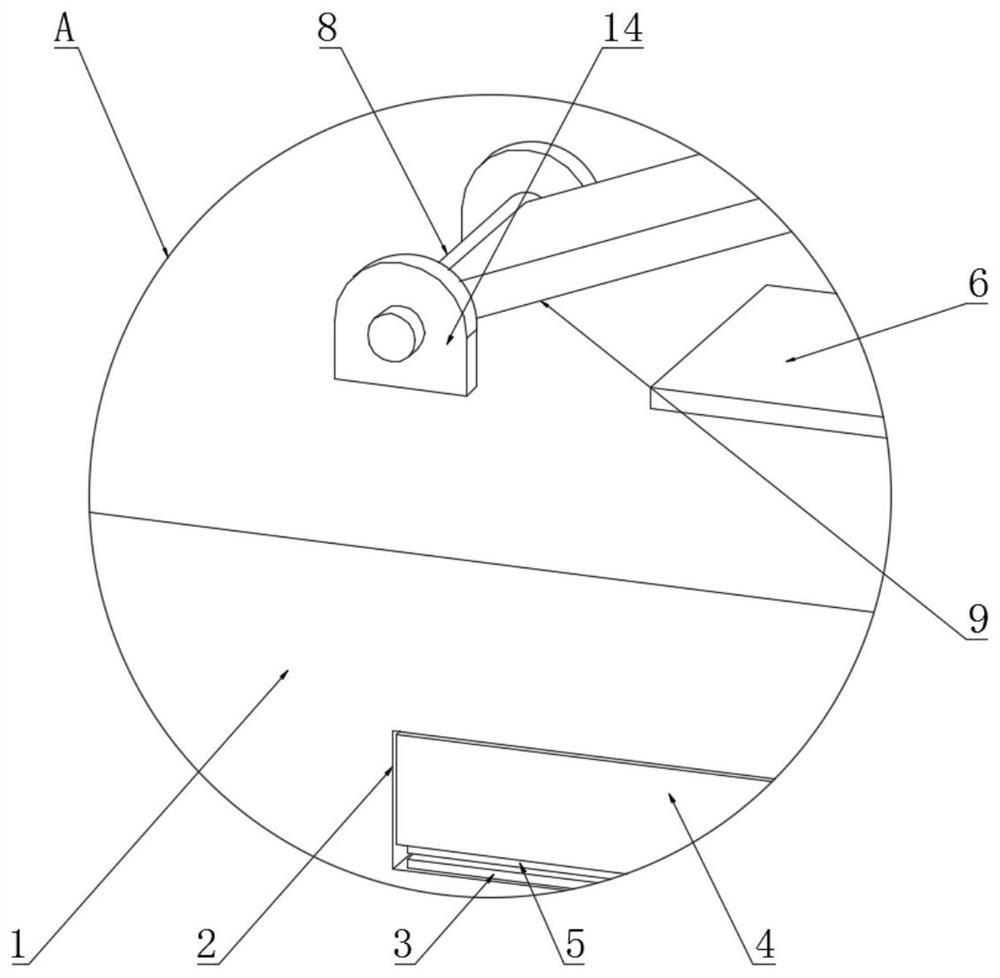

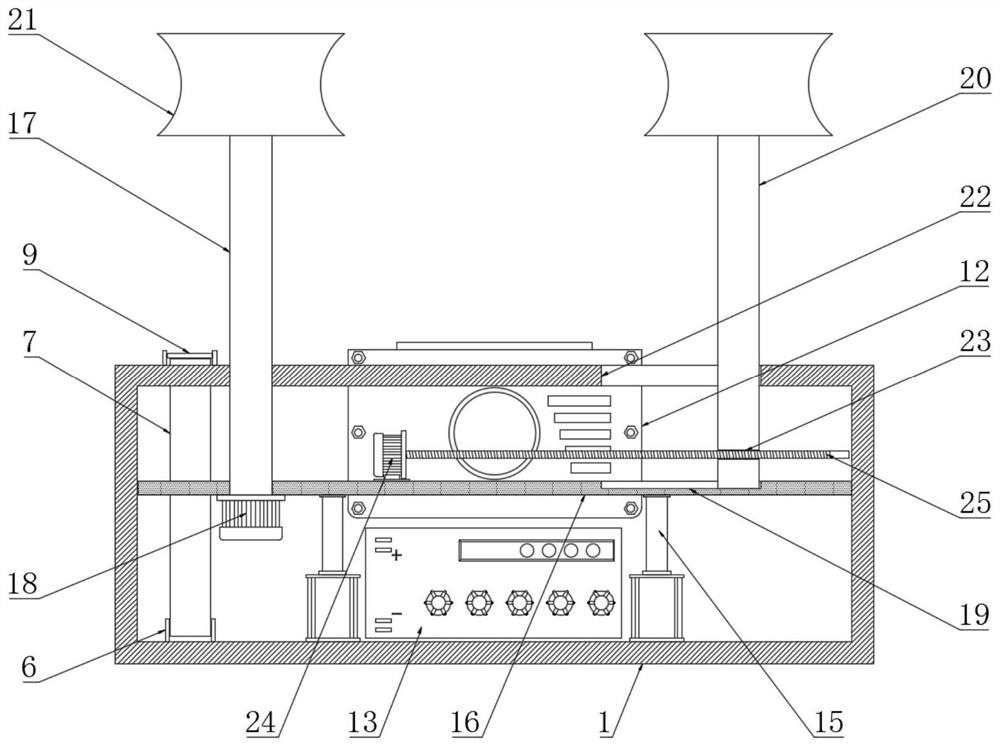

[0028] Such as Figure 1-3 As shown, the present invention provides a technical solution, an overhead transmission line linear continuous tube X-ray flaw detection robot, including a protective box 1, the surfaces of both sides of the protective box 1 are provided with air vents 2, and the bottom of the air vent 2 is provided with a first magnet 3. The top of the air vent 2 is connected to the dustproof plate 4 through the rotating shaft, and the bottom of the dustproof plate 4 is provided with the second magnet 5. In order to ensure the mutual attraction between the first magnet 3 and the second magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com