Method and device for testing shot-peening speed by means of rotary motion

A technology of rotary motion and shot peening, applied in the field of speed measurement, can solve the problems of expensive equipment and inability to meet research needs, and achieve the effects of simple and compact structure, low cost, and easy manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment, obviously, described here is only a part of example of the present invention, not all examples, for those of ordinary skill in the art, without departing from the principle of the present invention Under the premise of the invention, some improvements and modifications can also be made, and these improvements and modifications should also be regarded as the protection scope of the present invention.

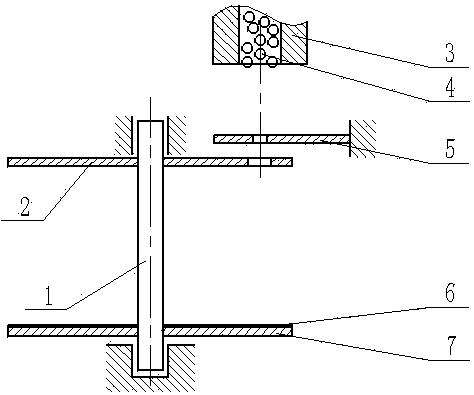

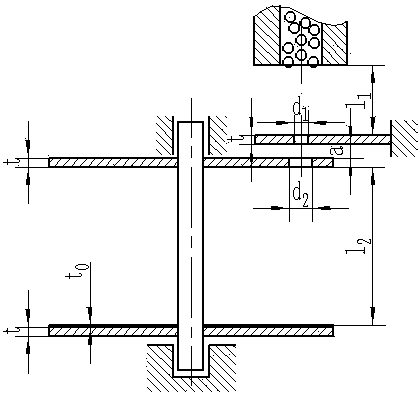

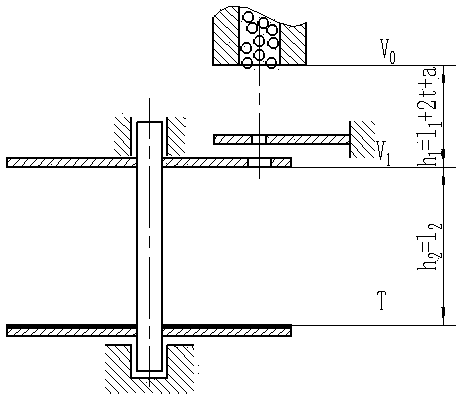

[0029] Such as figure 1 and figure 2 As shown, a device for testing shot peening speed by using rotary motion, including nozzle 3, projectile 4, fixed screening plate 5, rotating screening plate 2, rotating baffle plate 7, rotating shaft 1 and deformed material layer 6; nozzle 3 is set downward The bottom of the nozzle 3 is provided with a fixed screening plate 5; the bottom of the fixed screening plate 5 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com