Protection cover for light giving-out hole of laser lamp

A light outlet and laser lamp technology, which is applied in the field of laser lamps, can solve the problems of not being able to play the role of the guard plate, the lens pollution of the light outlet, and reducing the service life of the mirror surface of the light outlet, so as to achieve the effect of convenient and quick use and prolonging the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

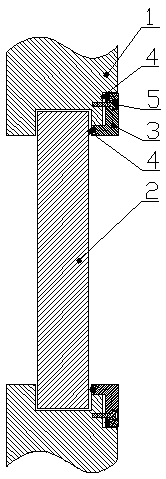

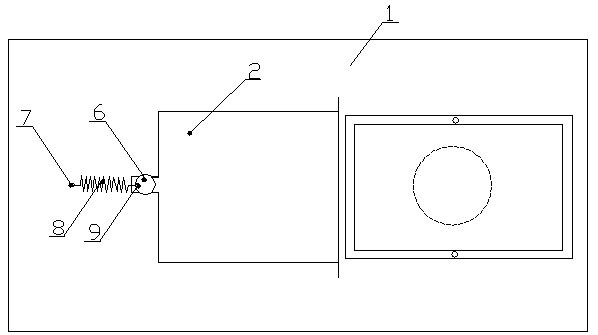

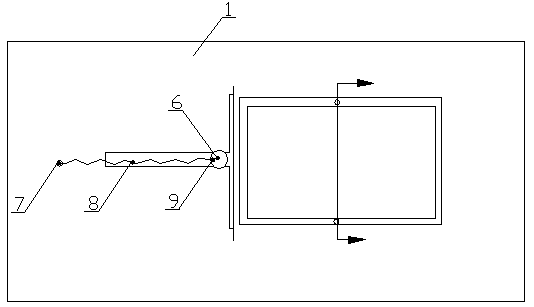

[0027] Embodiment: first as figure 1 In the conventional technology shown, when the position of the light emitting port of the laser light needs to be closed and protected, directly hold the round handle 6 and move it to the right, the round handle 6 will drive the movement of the baffle plate 2 to effectively protect the light emitting port, and hold the round handle 6 when opening. The handle 6 will drive the baffle 2 to perform an opening process.

[0028] In this technology, a sealing assembly is added and designed. The sealing ring provided on the cover plate 3 of the sealing assembly performs a complete sealing effect on the closed baffle 2. When the round handle 6 is held and moved to the right to drive the baffle 2 When moving to effectively protect the light-emitting port, directly turn the screw 5 to completely seal the cover plate 3 and the baffle plate 2. Since the sealing ring 4 on the cover plate 3 is designed in a hollow shape, it will The lower deformation can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com