A fully automatic wood scraping putty assembly line equipment

A putty scraping and assembly line technology, which is applied in the field of automatic wood putty scraping assembly line equipment, can solve problems such as time-consuming and labor-intensive reduction of production efficiency, and achieve the effects of low failure rate, increased efficiency, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] With reference to the accompanying drawings, the workflow of the present invention is described in detail below:

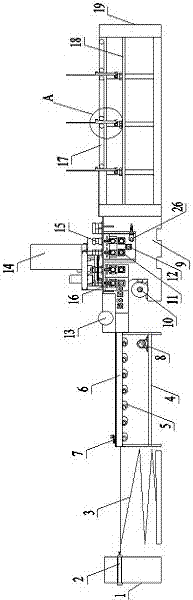

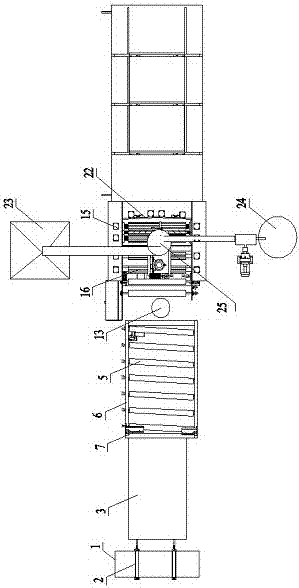

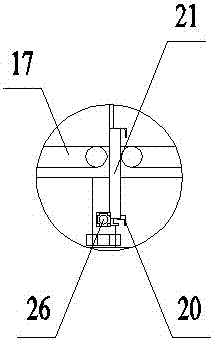

[0016] Such as figure 1 , figure 2 and image 3 As shown, a fully automatic wood puttying assembly line equipment includes a control box, a push plate mechanism, a raw material board lifting table, a wood board transmission and correction mechanism, a putty powder feeding mechanism, a raw material glue feeding mechanism, a stirring and unloading mechanism, a putty scraping mechanism and The plate connecting mechanism, the pushing plate mechanism, the raw material plate lifting platform, the plank conveying and correcting mechanism, the putty scraping mechanism and the plate connecting mechanism are arranged side by side in sequence; wherein the plank conveying and correcting mechanism includes a motor A8, a plank conveying and correcting mechanism frame 4, a plank Quantity sensing control device 7, transmission shaft 5 and side plate 6, wherein said tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com