Elastic piece and cap assembling device of zipper puller assembling machine

An assembly device and assembly machine technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve problems such as affecting assembly efficiency and increasing assembly processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

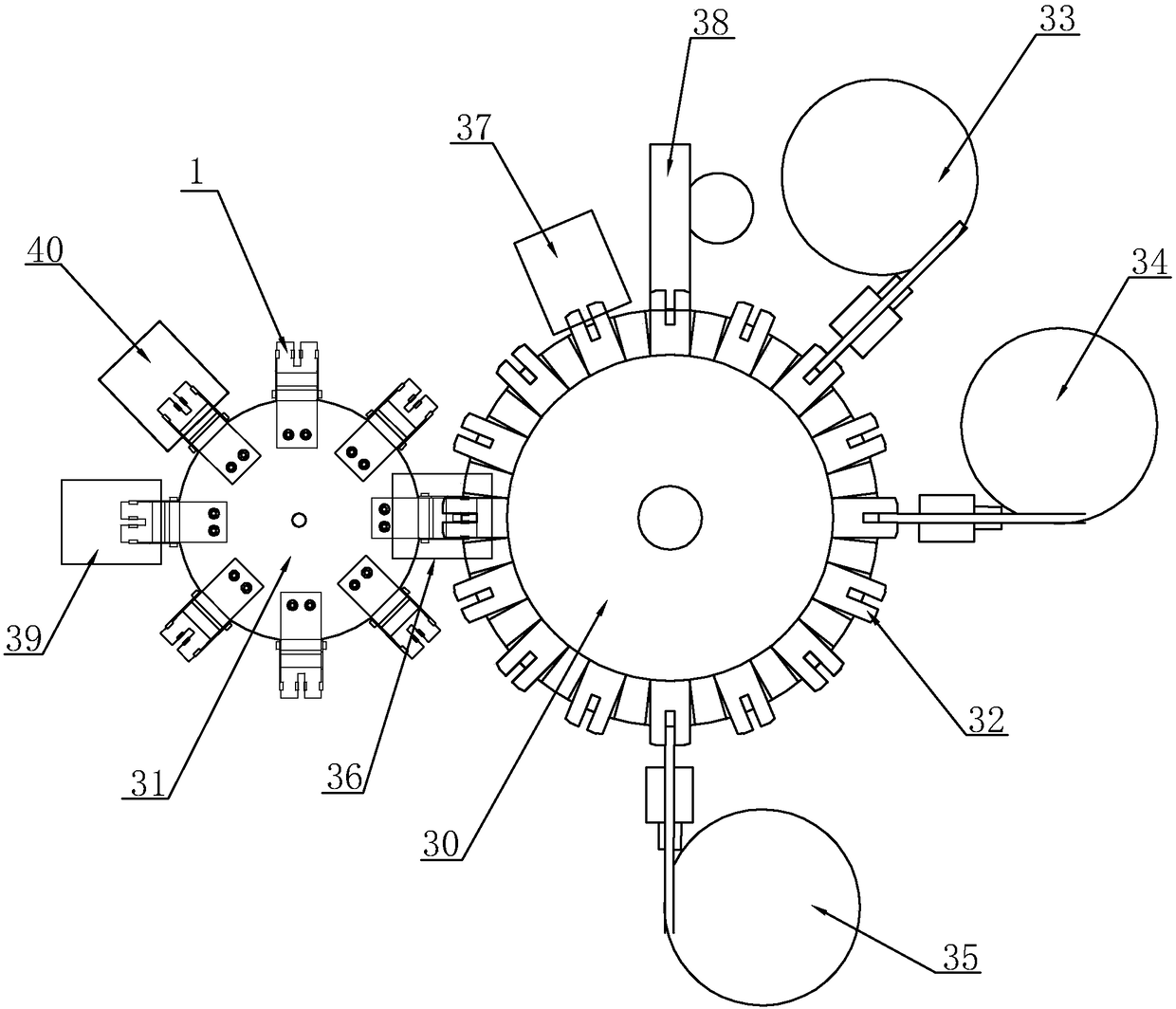

[0049] A zipper puller assembly machine such as figure 1 As shown, it includes a main turntable 30 and an auxiliary turntable 31, and the main turntable 30 is provided with a transfer area 32 for clamping slider bodies in the circumferential direction; a slider body assembly device 33 and a pull tab assembly device are sequentially distributed in the circumferential direction of the main turntable 30. 34. Horse hook assembly device 35, shrapnel cap assembly device 36, physical impact point 37 and discharge device 38. The structures of the main turntable 30, the transfer area 32, the slider body assembly device 33, the pull piece assembly device 34, the hook assembly device 35, the physical impact point 37 and the discharge device 38 are all in the prior art. The slider body enters the transmission area 32 through the slider body assembly device 33, and the main turntable 30 realizes intermittent indexing rotation through its transmission device to drive the slider body to asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com