Combined supporting and pressing mechanism capable of preventing pressing and sinking

A compression mechanism and anti-sinking technology, applied in the direction of support, metal processing machinery parts, clamping, etc., can solve the problems of affecting the positioning accuracy of the positioning surface of the tooling, affecting the processing quality of parts, reducing the service life of the tooling, etc., to improve product processing pass rate, save clamping time, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

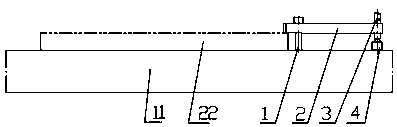

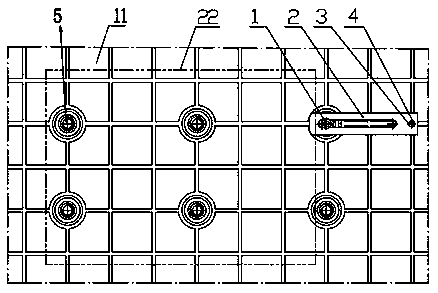

[0028] refer to figure 1 , figure 2 .

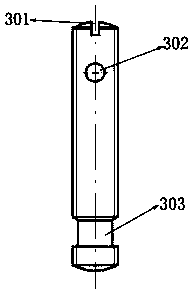

[0029] An anti-pressure and anti-subsidence combined support and compression mechanism, including a tooling base 11, a combined support component and a compression component, characterized in that: the tooling bottom 11 is provided with a threaded hole 5, and the combined support component includes an adjustable support Screw 3 and smooth pressing block 4; one end of the adjustable support screw 3 is provided with a notch 301 and a through hole 302, and the other end is provided with an undercut 303, and the entire screw rod is provided with threads; the smooth pressing block 4 A threaded hole 5 and an inner hole 401 are provided; the pressing assembly includes a moving platen 2 and a pressing screw 1; the moving platen 2 is provided with an annular groove 201 and a threaded hole 5; the pressing screw 1 passes through the annular groove 201 is inserted into the threaded hole 5 of the tooling base 11, and is connected with the screw th...

Embodiment 2

[0034] An anti-pressure and anti-subsidence combined support and compression mechanism, including a tool base 11, a combined support component and a compression component, and is characterized in that: the tool base 11 is provided with a threaded hole 5, and the combined support component includes an adjustable support Screw 3 and smooth pressing block 4; one end of the adjustable support screw 3 is provided with a notch 301 and a through hole 302, and the other end is provided with an undercut 303, and the entire screw rod is provided with threads; the smooth pressing block 4 A threaded hole 5 and an inner hole 401 are provided; the pressing assembly includes a moving platen 2 and a pressing screw 1; the moving platen 2 is provided with an annular groove 201 and a threaded hole 5; the pressing screw 1 passes through the annular groove 201 is inserted into the threaded hole 5 of the tooling base 11, and is connected with the screw thread.

Embodiment 3

[0036] An anti-pressure and anti-subsidence combined support and compression mechanism, including a tool base 11, a combined support component and a compression component, and is characterized in that: the tool base 11 is provided with a threaded hole 5, and the combined support component includes an adjustable support Screw 3 and smooth pressing block 4; one end of the adjustable support screw 3 is provided with a notch 301 and a through hole 302, and the other end is provided with an undercut 303, and the entire screw rod is provided with threads; the smooth pressing block 4 A threaded hole 5 and an inner hole 401 are provided; the pressing assembly includes a moving platen 2 and a pressing screw 1; the moving platen 2 is provided with an annular groove 201 and a threaded hole 5; the pressing screw 1 passes through the annular groove 201 is inserted into the threaded hole 5 of the tooling base 11, and is connected with the screw thread.

[0037] Further, the notch 301 of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap