Guide wheel rail vehicle and rail

A technology for rail vehicles and guide wheels, applied in the field of rail transportation, can solve the problems of complex composition and structure of turnouts, large turning radius, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

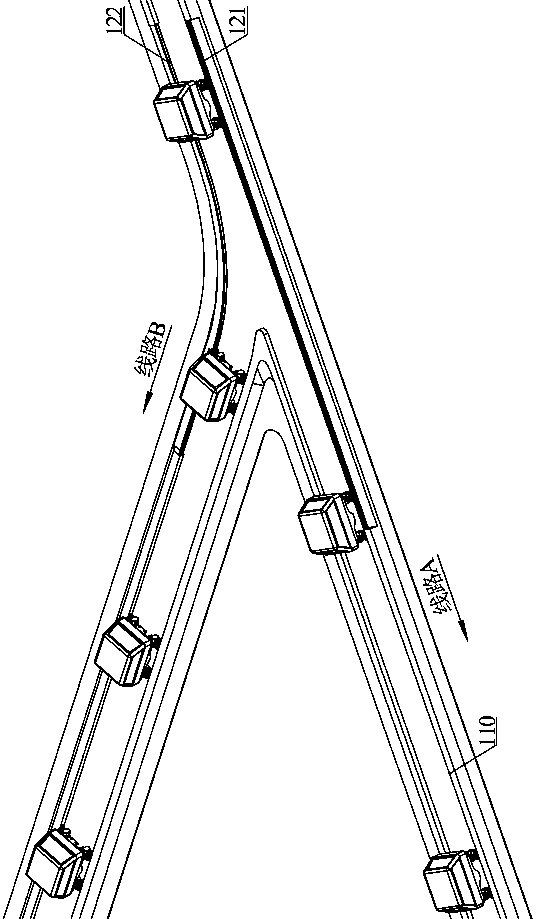

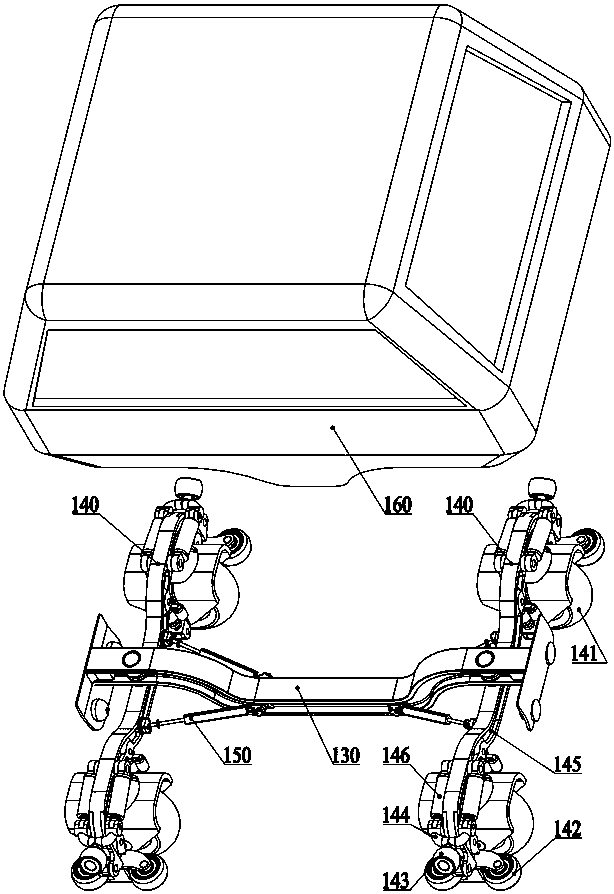

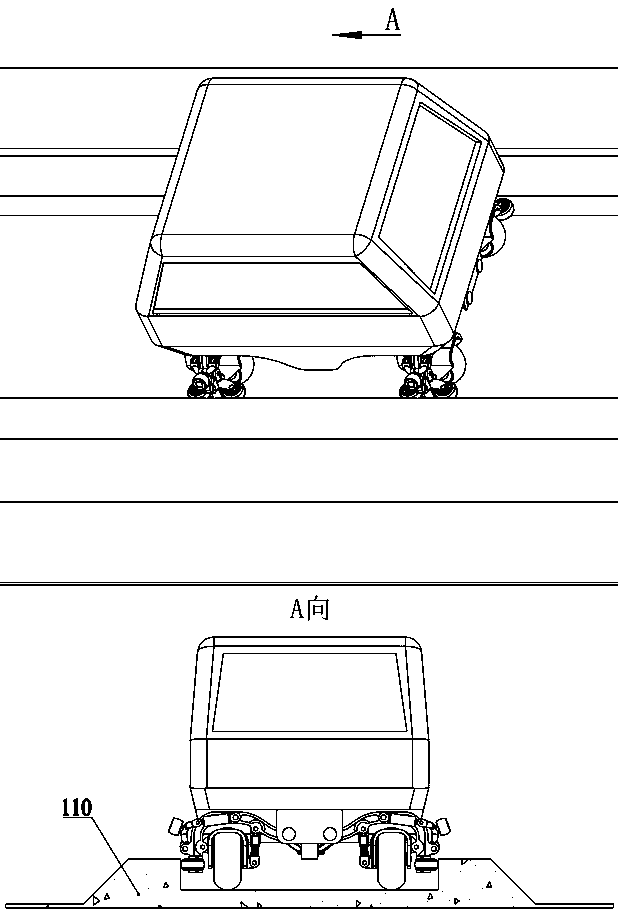

[0047] figure 1 A scenario in which this embodiment is used is shown. In this embodiment, the running devices of the vehicle are all distributed in the lower part of the vehicle, which are two sets of guide wheel running device assemblies that have both guiding and driving capabilities and are integrated with a guiding regulation mechanism—the axle 140. The two sets of axles pass through It is hinged with the vehicle frame 130 to realize structural integration. The detailed structure of the whole vehicle structure and the axle is as follows: figure 2 As shown, the carriage 160 is installed on the vehicle frame 130, and the vehicle axle 140 is hinged with the vehicle frame 130 in the middle of itself, and also has a steering auxiliary cylinder 150 to stabilize the direction.

[0048] The driving wheel 141 is fixedly connected with the axle beam 145 (excluding shock absorption); the guide wheel 142 is fixedly installed on both sides of the vehicle frame beam 145 . The guide ...

no. 2 Embodiment

[0059] Figure 5 A scenario in which this embodiment is used is shown. In this embodiment, the running gear of the vehicle is distributed on the top and bottom of the vehicle, including two sets of guide wheel running gear assemblies 240 and two sets of guiding control devices 250, and all components of the running gear are structurally integrated through the vehicle frame 230 .

[0060] The detailed structure and composition of the driving device are as follows: Image 6 , Figure 7 As shown, the four guide wheels 242 on the upper part of the guide wheel walking device assembly 240 realize the steering control of the driving wheel 241 through the rotating shaft 243 (integral fixed connection form); the guide control device 250 includes a pressing wheel 251 (the specific function of the guide wheel Positioning), wheel shaft 252, telescopic arm 253, control oil cylinder 254, wheel shaft locking pin 255, telescopic arm locking element 256, etc., under the actuation of control...

no. 3 Embodiment

[0066] Figure 11 A scenario in which this embodiment is used is shown. In this embodiment, the running devices of the vehicle are all distributed at the bottom of the vehicle, and the principle of bridge steering is applied, which are two sets of guide wheel running device assemblies 340 with the same structure and symmetrically installed. The two sets of assemblies are structurally integrated by being hinged with the frame 350, and four steering auxiliary cylinders 360 are used to control the driving stability of the vehicle and to control the driving direction of the vehicle on road sections without guide rails. The compartment 370 is fixedly connected to the vehicle frame 350 .

[0067] The structure of the guide wheel walking device is as follows: Figure 13 As shown, the vehicle is carried and driven by the road wheels 342 when driving; two guide wheels 345 are arranged under the middle part of the integral axle 341 to control the direction of travel of the vehicle alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com