Leaf spring assembly having leaf spring and at least one bearing bore retainer

A technology for retaining devices and bearing holes, which is applied in the field of leaf spring components, can solve problems such as inability to ensure a uniform fiber composite structure, and achieve the effect of high force application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

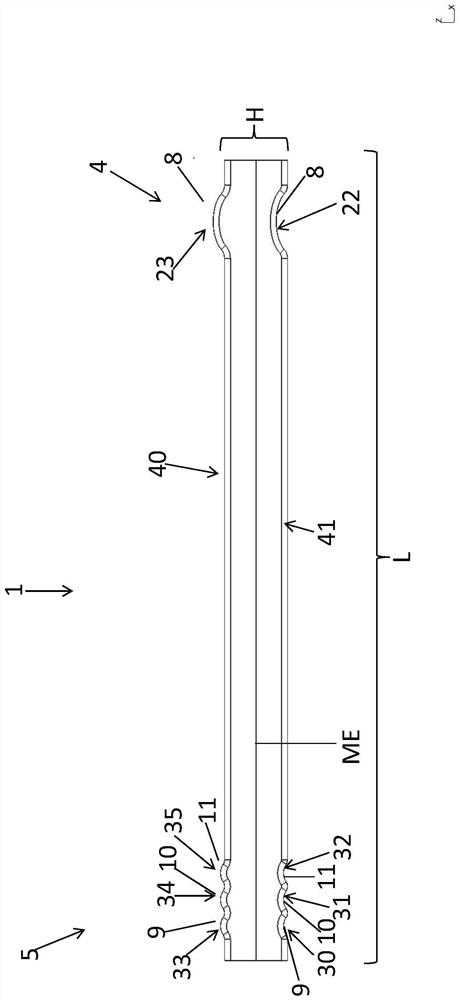

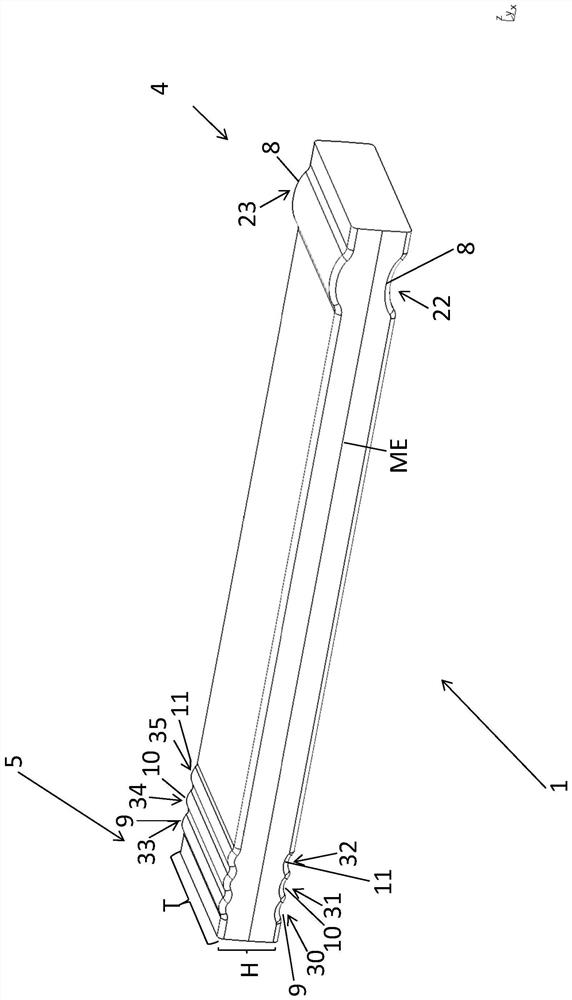

[0029] exist figure 1 and 2 In , an embodiment of a leaf spring 1 of a leaf spring assembly according to the invention is shown in side and perspective views. In this case, the leaf spring 1 made of fiber composite material has a length L and a height H and a width T at its ends 4 and 5 . In this case, the height H is substantially perpendicular to the width T, so that the height H and the width T define the cross-section of the leaf spring 1 in its longitudinal extent along the length of the ends 4 and 5 . In this case, the cross section is substantially rectangular, wherein the corners are rounded. Due to the uniform cross-section on the longitudinal extent of the ends 4 and 5 of the leaf spring 1, the ends 4 and 5 of the leaf spring 1 may require no material addition or material reduction in order to be used in the leaf spring assembly according to the invention .

[0030] Here, the leaf spring 1 is figure 1 and 2 The central right-hand end 4 has a corrugation 8 , whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com