A kind of preparation method of aluminum carbon composite material

A technology of aluminum-carbon composite material and aluminum alloy powder, which is applied in the field of preparation of aluminum-carbon composite material, can solve problems such as not being well realized, and achieve the effects of short residence time at high temperature, avoiding harmful interface reactions, and improving preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

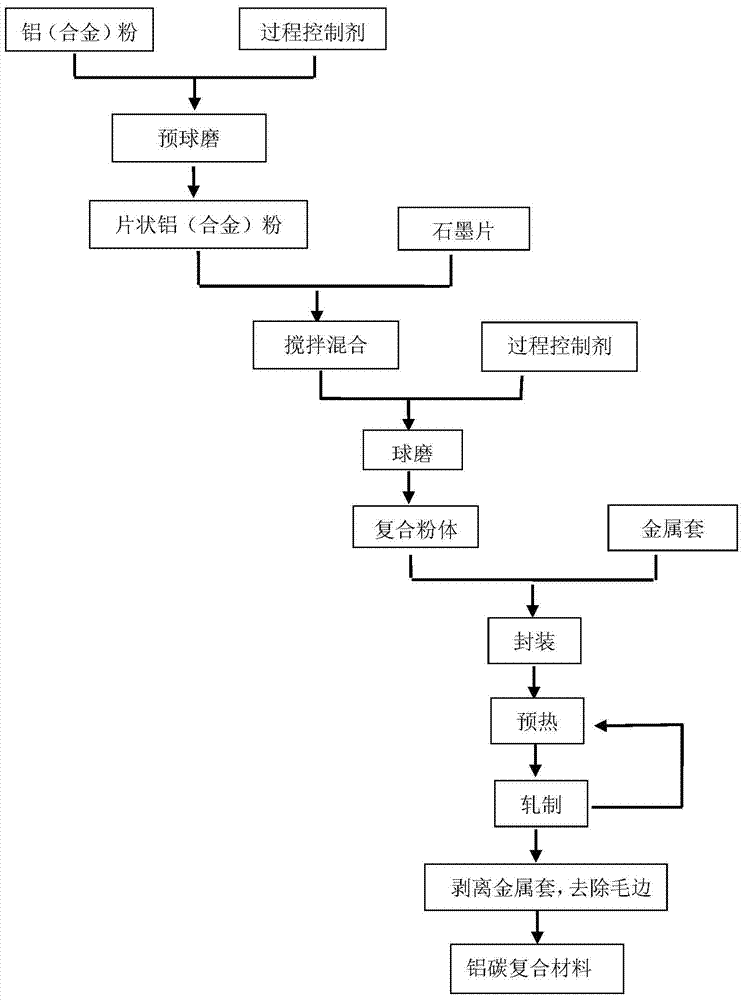

[0029] A method for preparing an aluminum-carbon composite material, specifically comprising the following steps:

[0030] 1) Mix 40g of pure aluminum powder with a particle size of 30 microns and 0.2g of stearic acid as a process control agent, and use a planetary ball mill for pre-milling. The ball-to-material ratio used for pre-milling is 10 / 1, and the speed is 200 rpm / minute, ball milling time 1 hour, made flake pure aluminum powder;

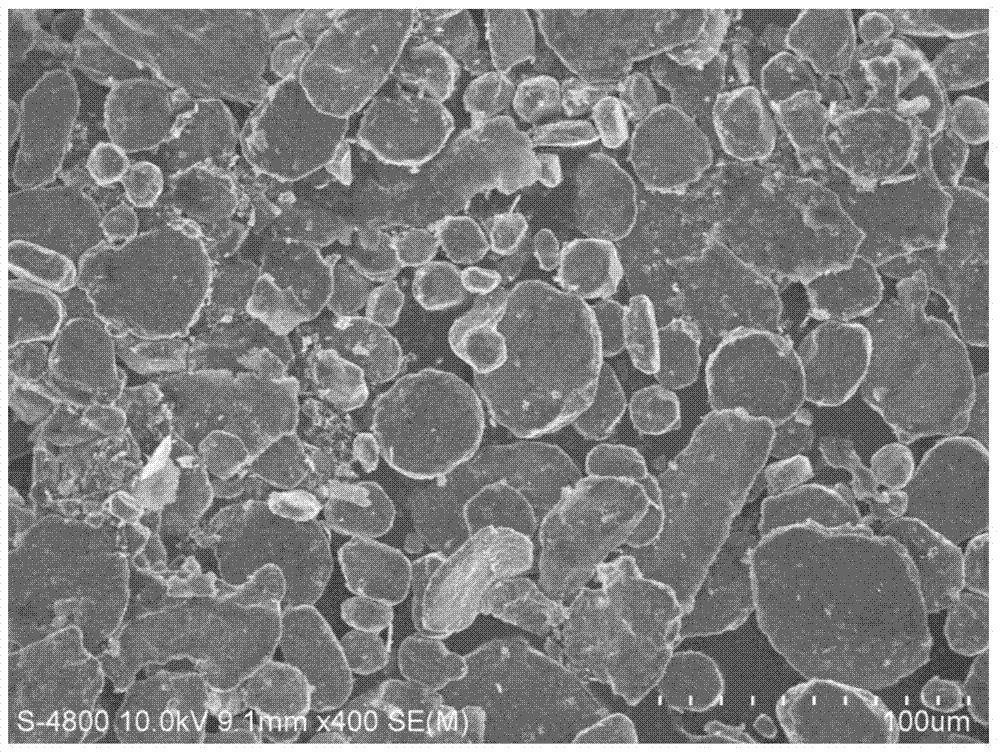

[0031] 2) The flaky pure aluminum powder obtained in step 1), 0.33g of process control agent stearic acid and 26.7g of natural flake graphite (provided by Qingdao Jinrilai Graphite Co., Ltd.) with a diameter of 300 microns and a thickness of 5 microns were three Those who mix, adopt planetary ball mill to carry out ball milling, the ball material ratio that adopts during ball milling is 10 / 1, rotating speed 300 revs / min, ball milling time 2 hours, make composite powder;

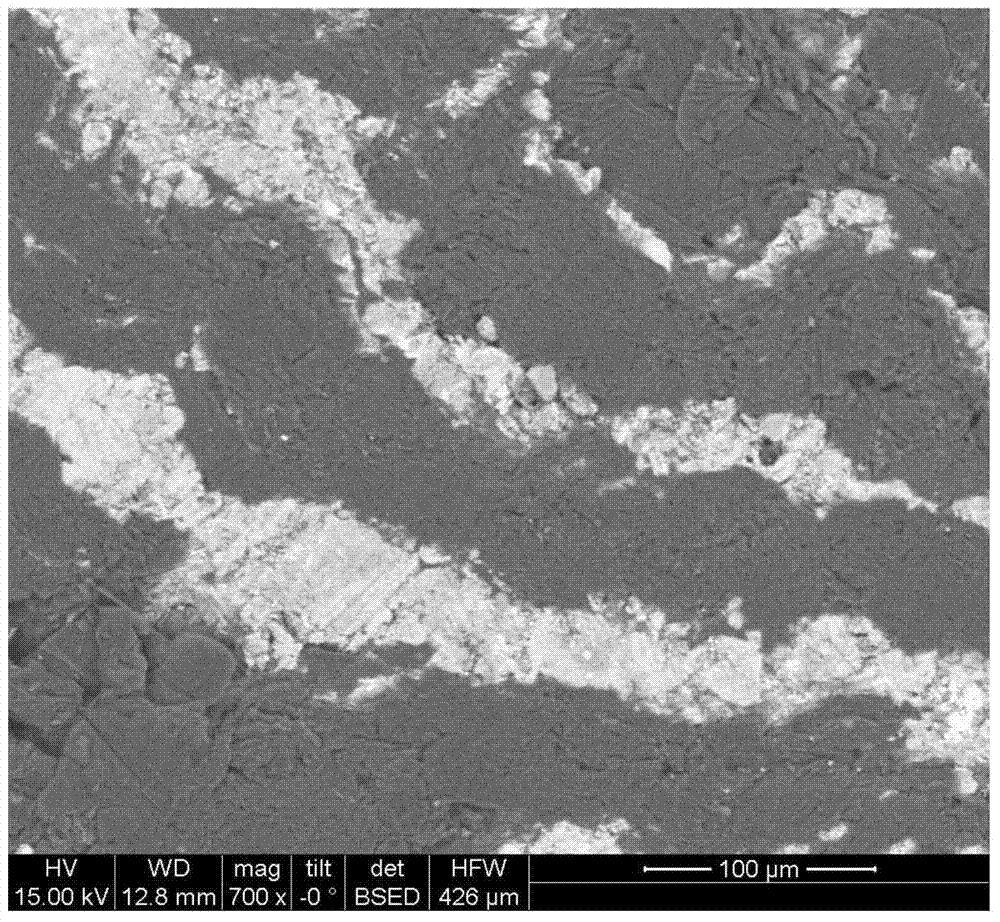

[0032] 3) Encapsulate the prepared composite powder in a metal slee...

Embodiment 2

[0034] Example 2 The difference between this example and Example 1 is that the mass of the graphite sheet in step 2 is 0.40g (1% by mass), and the process control agent stearic acid is 0.2g, so that the thermal conductivity of the composite material is 150W / mK, the coefficient of thermal expansion is 18×10 -6 m / K.

Embodiment 3

[0035] Example 3 The difference between this example and Example 1 is that the mass of the graphite sheet in step 2) is 40g, the process control agent stearic acid is 0.4g, and the thermal conductivity of the composite material obtained is 270W / mK, and the thermal expansion coefficient is 7 ×10 -6 m / K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com