Damping mechanism for shift selector assembly and shift selector assembly comprising said damping mechanism

A gear selector and damping mechanism technology, which is applied in the field of damping mechanisms, can solve problems such as excessive friction, and achieve the effects of prolonging the usable life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

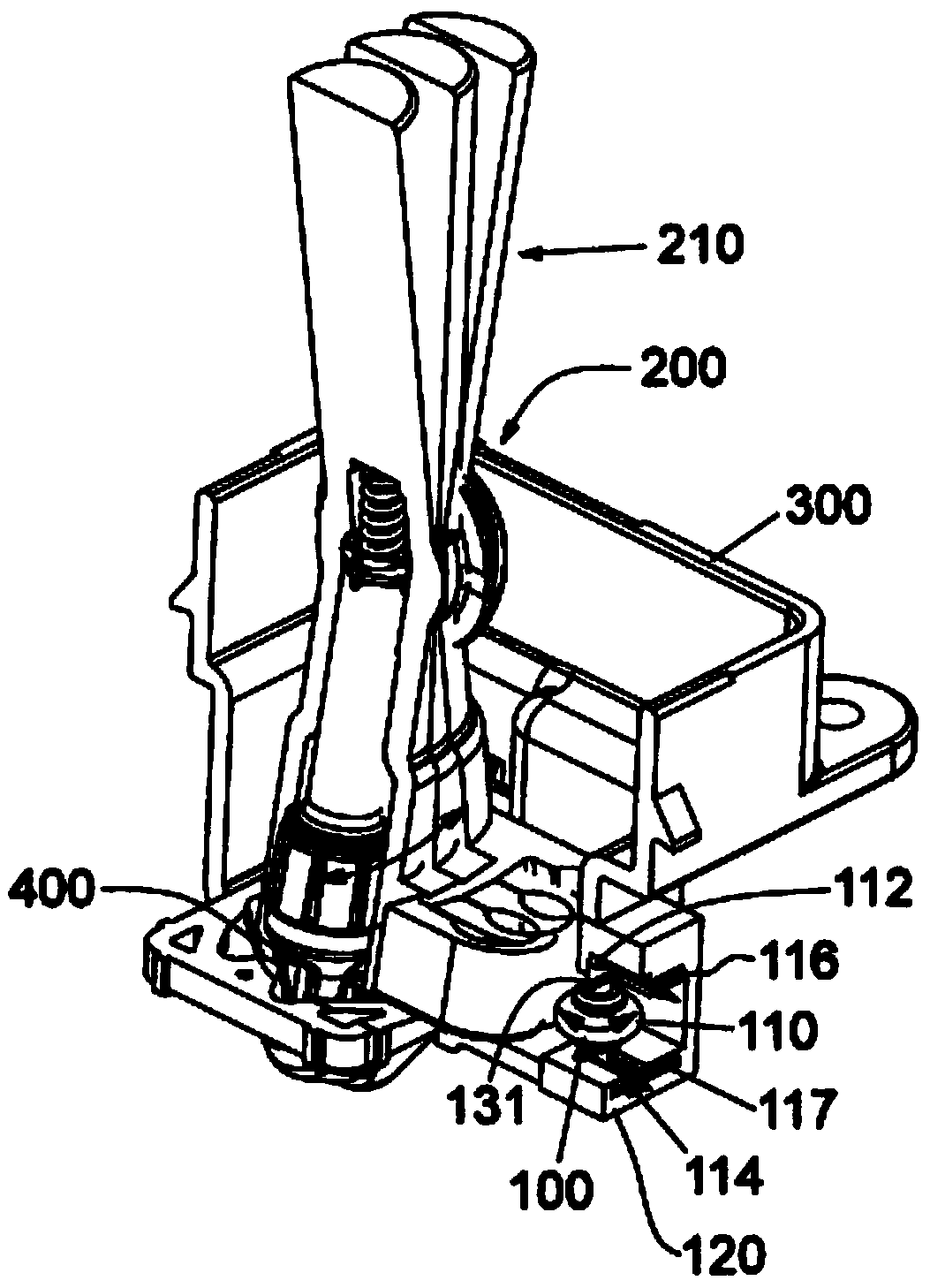

[0028] Hereinafter, non-limiting examples of the present damping mechanism are described with reference to the accompanying drawings. In the examples described, like reference numerals refer to like parts throughout the several views of the drawings.

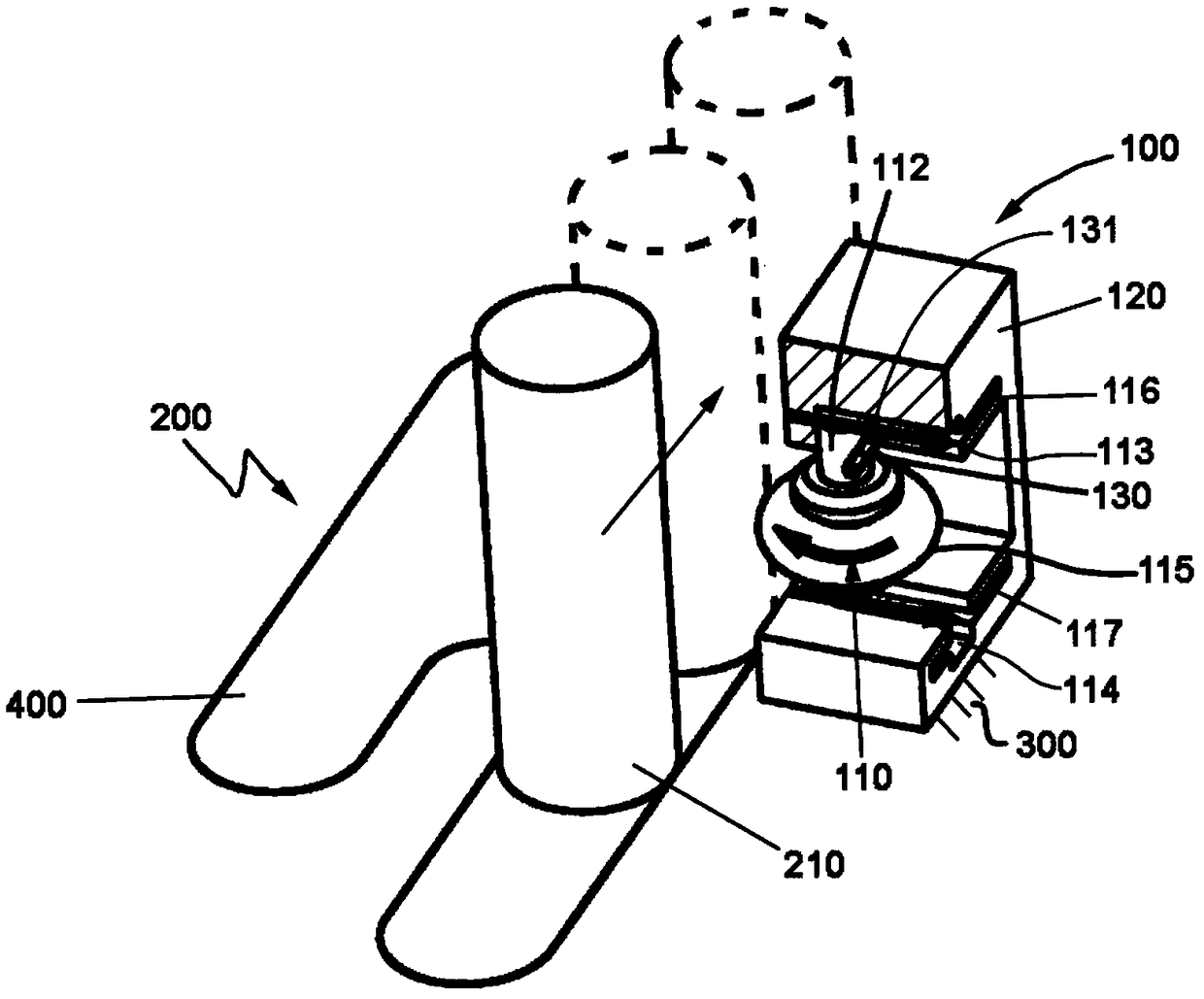

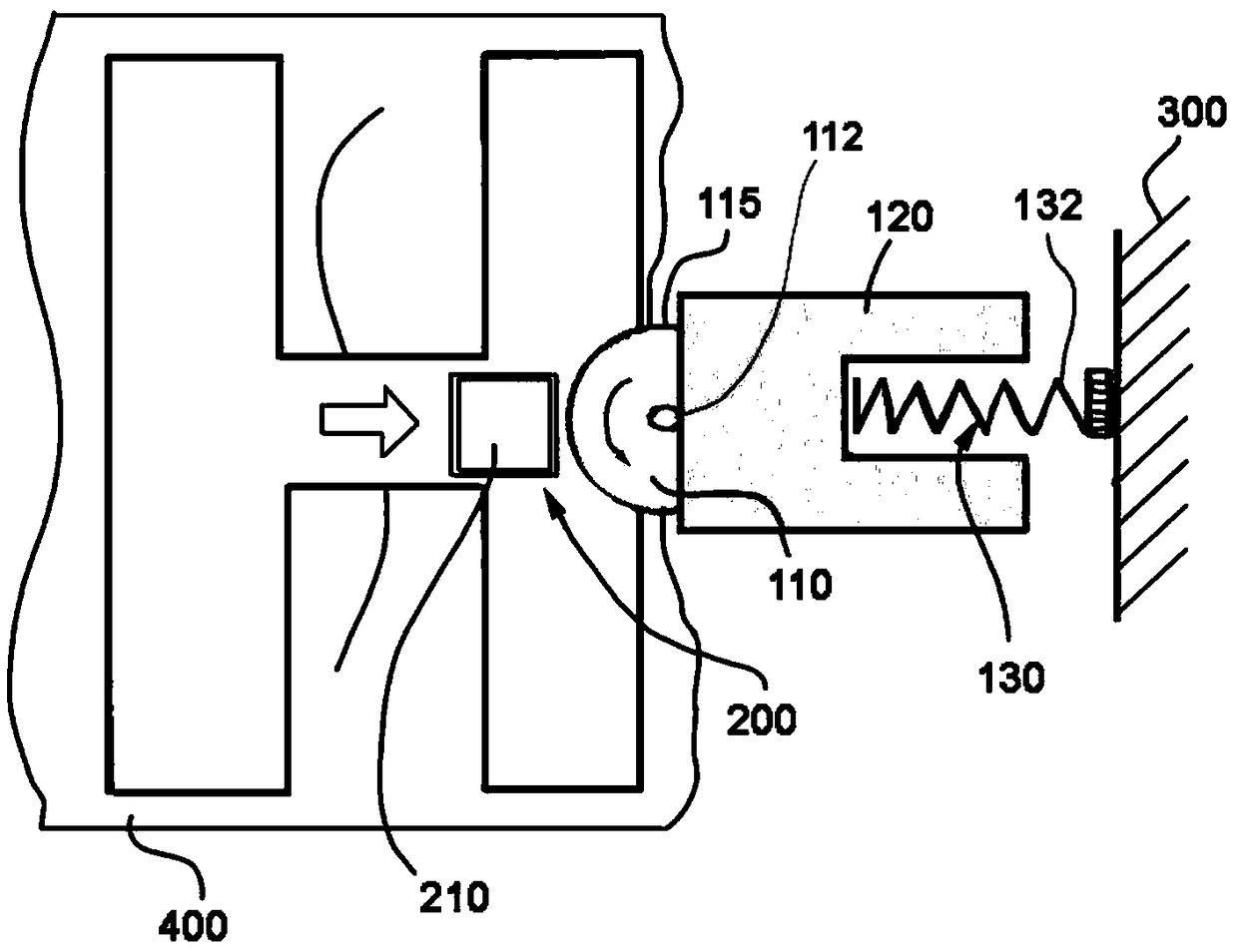

[0029] The damping mechanism 100 is shown incorporated in a gear selector assembly 200 of a motor vehicle transmission. The gear selector assembly 200 includes a fixed part 300 and a movable part, which corresponds to the shift lever 210 in this example. The shift lever 210 is movable relative to the fixed part 300 . In this example, the stationary component 300 is part of the shifter cover of the gear selector assembly 200 , although the stationary component 300 could be a component attached to the shifter cover.

[0030] Such as image 3 and Figure 4 As shown, the shift lever 210 is movable relative to the stationary member 300 in different directions that are biased onto the contoured surface 400 . Contoured surface 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com