Preparation technology and equipment for sulfuric acid for coking industry

A process equipment and industry technology, applied in the field of sulfuric acid preparation process and equipment in the coking industry, can solve the problems of accelerated corrosion, corrosion, and unimaginable consequences of storage tanks, achieve stable output concentration of dilute acid, easy lining with anti-corrosion materials, The effect of solving automation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

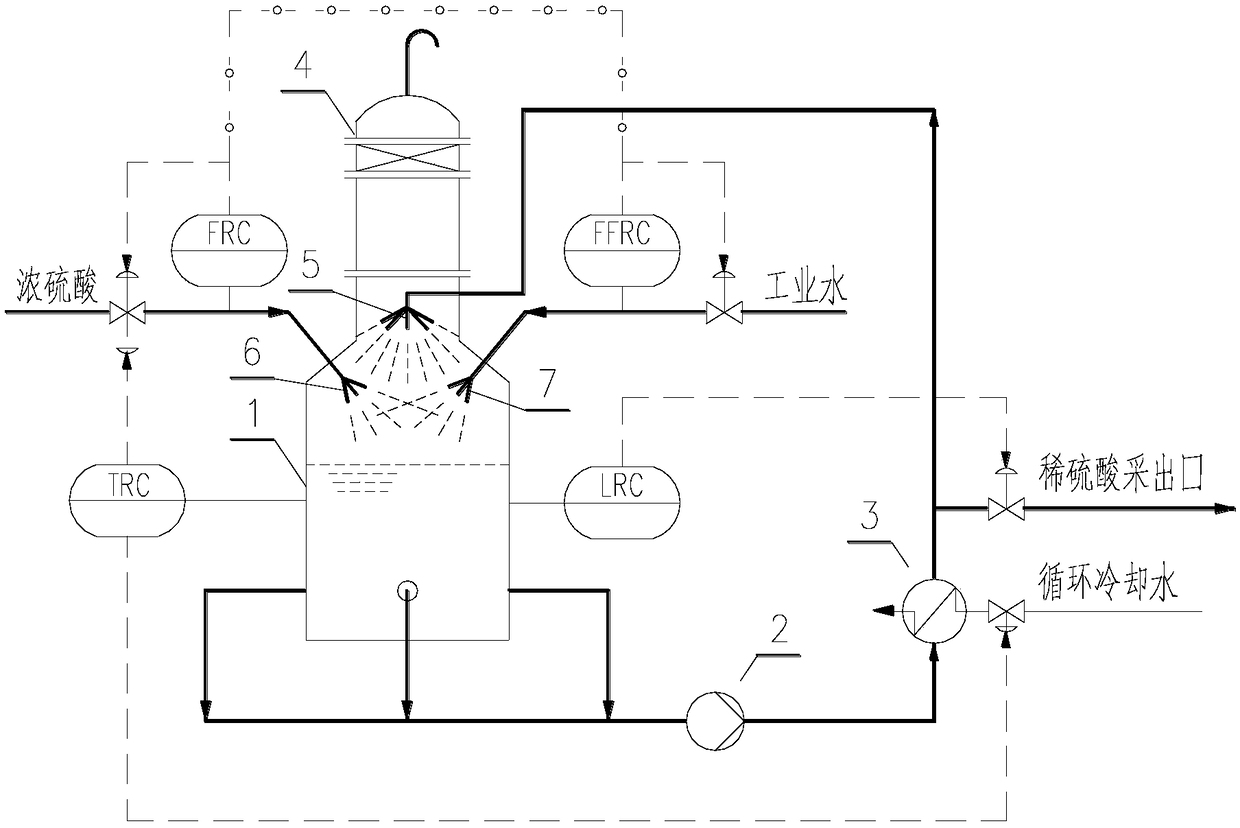

[0036] See figure 1 As shown, a kind of sulfuric acid preparation process equipment for the coking industry involved in the present invention includes an acid distributing tower 1, a circulating pump 2, a circulating cooler 3, a demister 4, a dilute acid nozzle 5, a flow recording regulating instrument FRC, and a flow recording Proportion regulating instrument FFRC, liquid level recording and regulating instrument LRC and temperature monitoring instrument TRC, the lower part of the acid distributing tower 1 is an acid distributing tank, and several dilute sulfuric acid extraction outlets are evenly distributed around it (to ensure the balanced preparation of dilute acid and the stability of the output concentration of dilute acid ) are gathered together and connected with circulating pump 2 and circulating cooler 3 successively, remove the dilute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com