Building engineering construction waste smashing and recycling device

A technology of construction engineering and recycling equipment, which is applied in the direction of grain processing, etc., and can solve the problem of material winding around the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

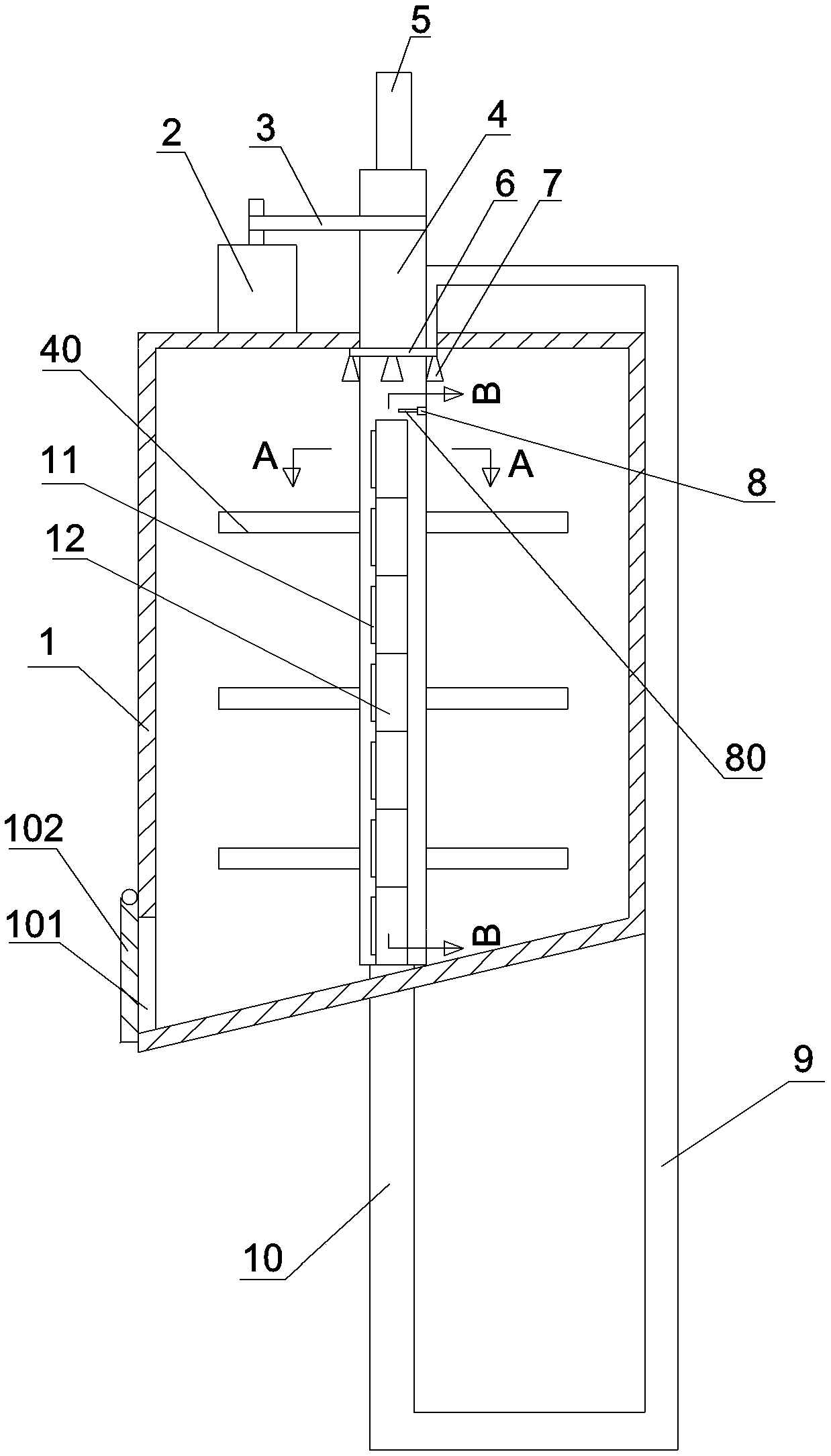

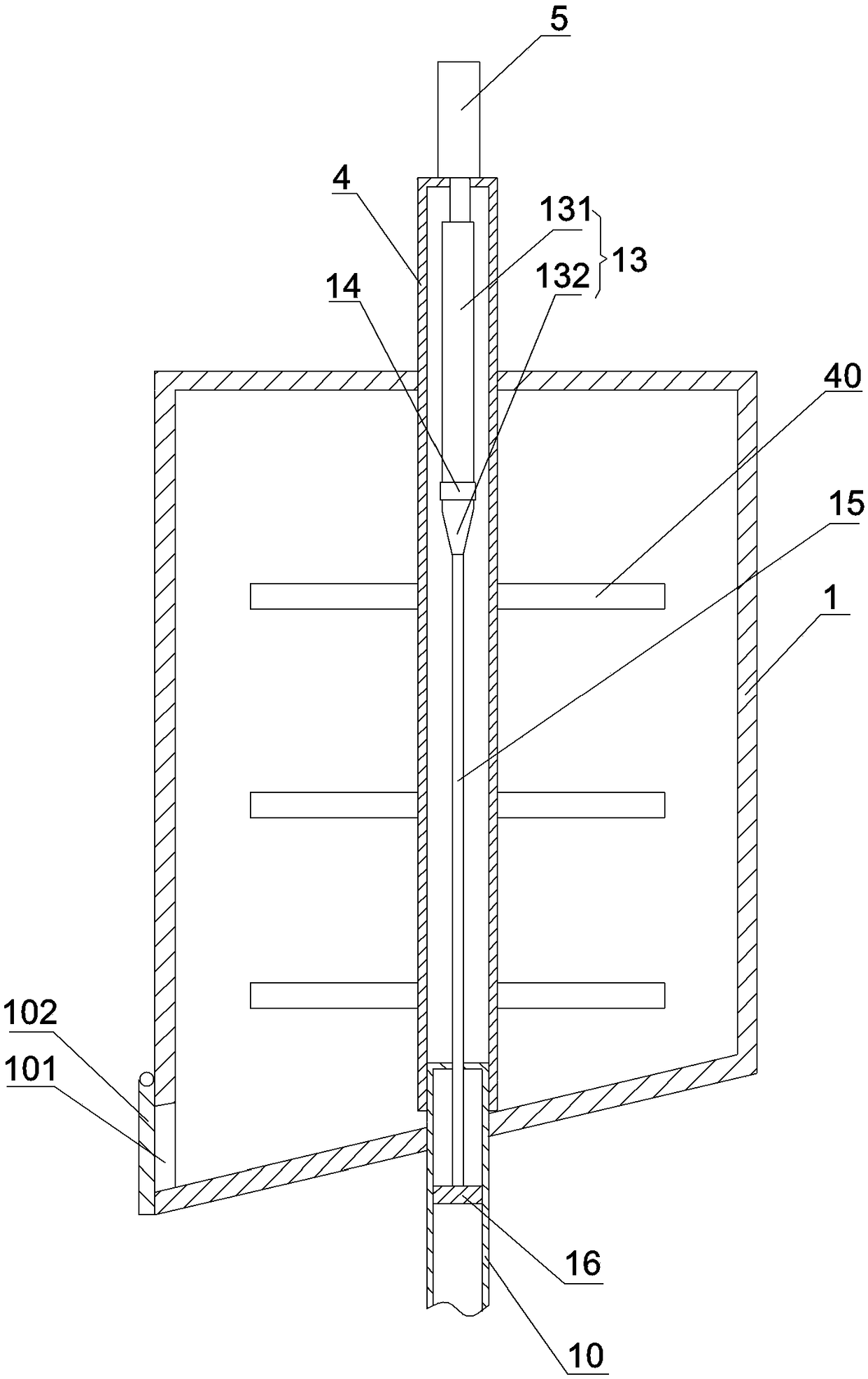

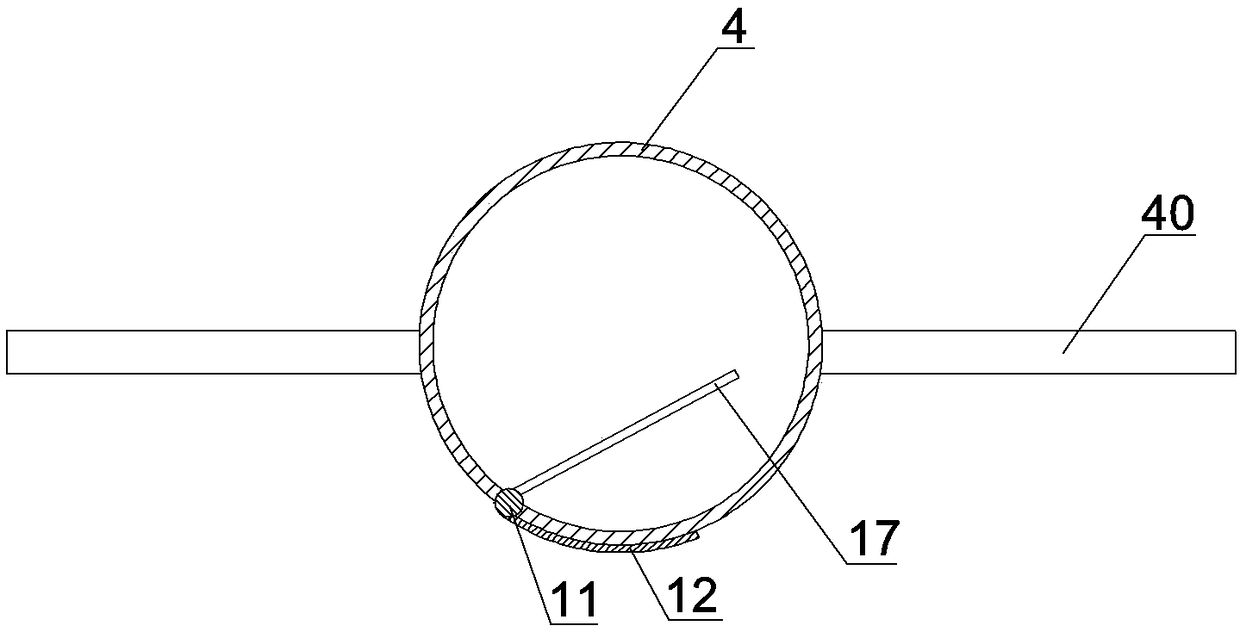

[0025] The reference signs in the drawings of the description include: crushing cylinder 1, discharge port 101, baffle plate 102, motor 2, belt 3, rotating shaft 4, crushing blade 40, hydraulic cylinder 5, annular air duct 6, blowing nozzle 7, knife Seat 8, cutter 80, pipeline 9, piston barrel 10, support shaft 11, protective sheet 12, falling part 121, raised part 122, driving rod 13, cylindrical part 131, conical part 132, magnet 14, connecting rod 15, Piston 16, rotating rod 17.

[0026] like figure 1 and figure 2 As shown, a construction waste crushing and recycling device in this embodiment includes a crushing cylinder 1, the inner bottom of the crushing cylinder 1 is arranged obliquely, and a discharge port 101 is provided on the side wall of the crushing cylinder 1 near the bottom of the crushing cylinder 1. , a baffle 102 is installed at the discharge port 101, a hollow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com