Liquid supply device and operation method thereof

A liquid supply and liquid technology, which can be applied to devices and coatings that apply liquid to the surface. It can solve the problems of high maintenance cost, complex structure and easy wear and tear, so as to optimize the liquid supply pressure and time and accurately control the supply amount. , Supply the effect of timely response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

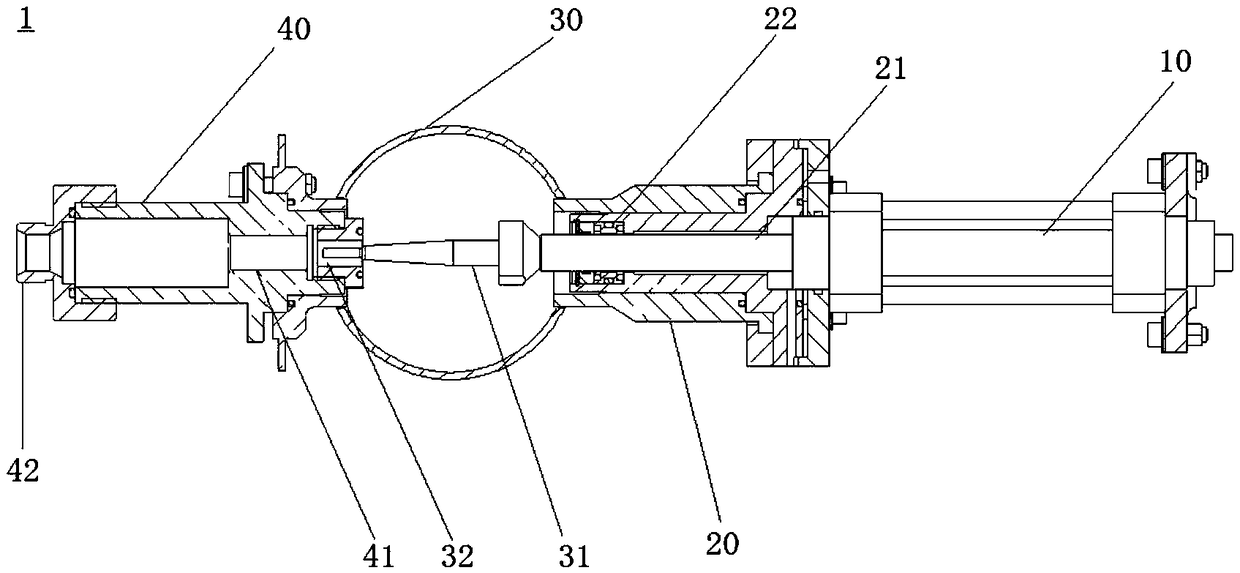

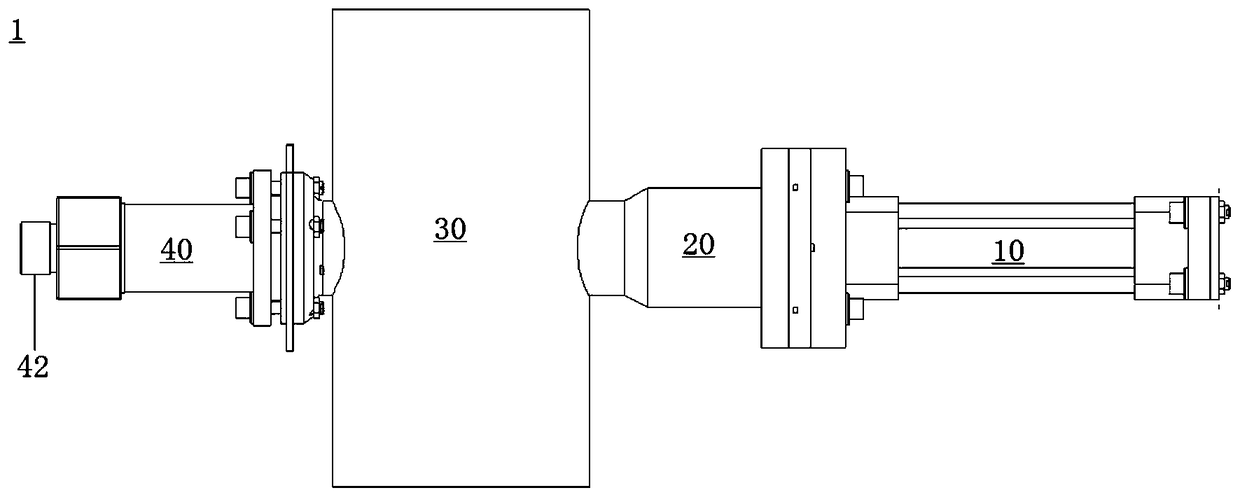

[0033] Please refer to figure 1 , 2 , is a structural diagram of a liquid supply device 1 of the present invention. Wherein, the liquid supply device 1 includes components such as a driving device 10 , a driving end sleeve 20 , a driving rod 21 , a driving end sealing element 22 , a liquid pipeline 30 , a cone valve 31 , a supply end sleeve 40 , and a supply end sealing element 41 . The liquid supply device 1 can be used, for example, as wax supply equipment in a painting workshop, but the application is not limited thereto, and the liquid supply device 1 can also be used as other liquid supply equipment.

[0034] The driving device 10 is used as a driving source to provide power to drive other components of the liquid supply device 1 . The driving device may adopt any suitable driving method, for example, it may be electric, that is, the driving device 10 may be, for example, a motor driving device. However, as the working environment of the liquid supply device 1 is diffe...

Embodiment 2

[0060] Embodiment 2 is another embodiment of the liquid supply device of the present invention. The main difference between the specific structure of Embodiment 2 and the above Embodiment 1 is that: the drive rod 21 and the drive end sleeve 20 are provided with threads. Specifically, the driving rod 21 can be a threaded screw. In Embodiment 2, the driving device 10 can perform rotational movement, and then the driving rod 21 and the cone valve 31 can be further rotated, and the driving rod 21 and the cone valve 31 can be rotated through the threads on the driving rod 21 and the driving end sleeve 20. Linear motion forward and backward to adjust the opening degree of cone valve 31.

Embodiment 3

[0062] Embodiment 3 is yet another embodiment of the liquid supply device of the present invention. In Embodiment 3, the opening degree of the cone valve 31 is determined by its rotation. Therefore, when the driving device 10 rotates, the driving rod 21 and the cone valve 31 can rotate accordingly, thereby adjusting the opening of the cone valve 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com