Cylinder metal raw material burr polishing machine

A technology of metal raw materials and cylinders, which is applied to metal processing equipment, parts of grinding machine tools, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems of affecting work efficiency and cylinder metal raw materials are easy to be stabbed by files, etc. , to achieve high work efficiency and avoid hand injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

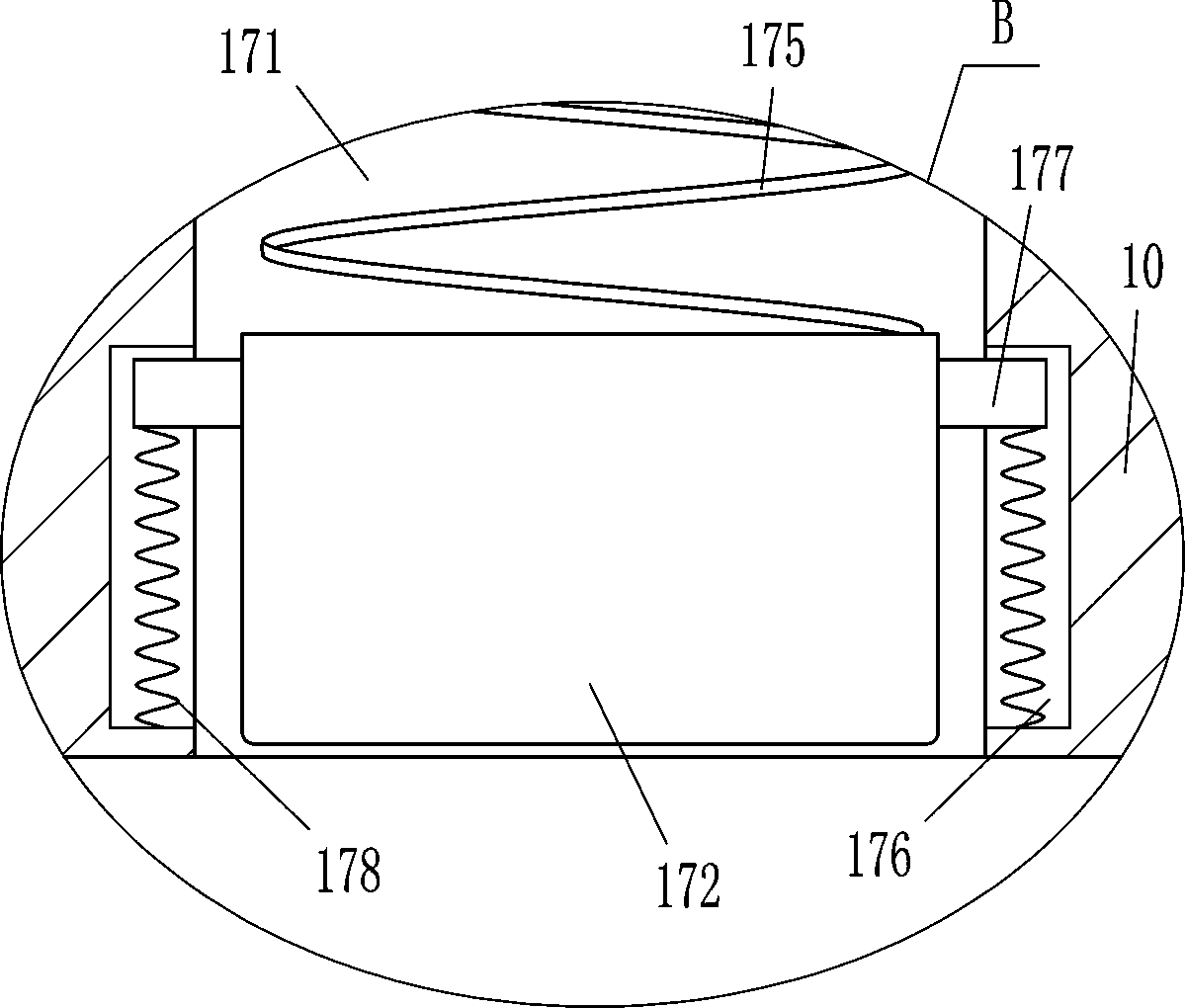

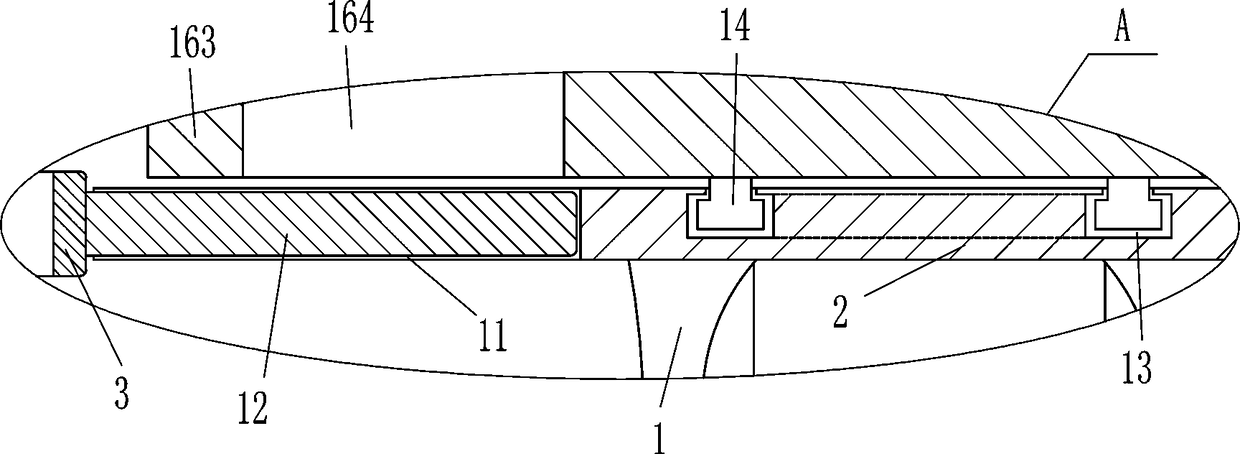

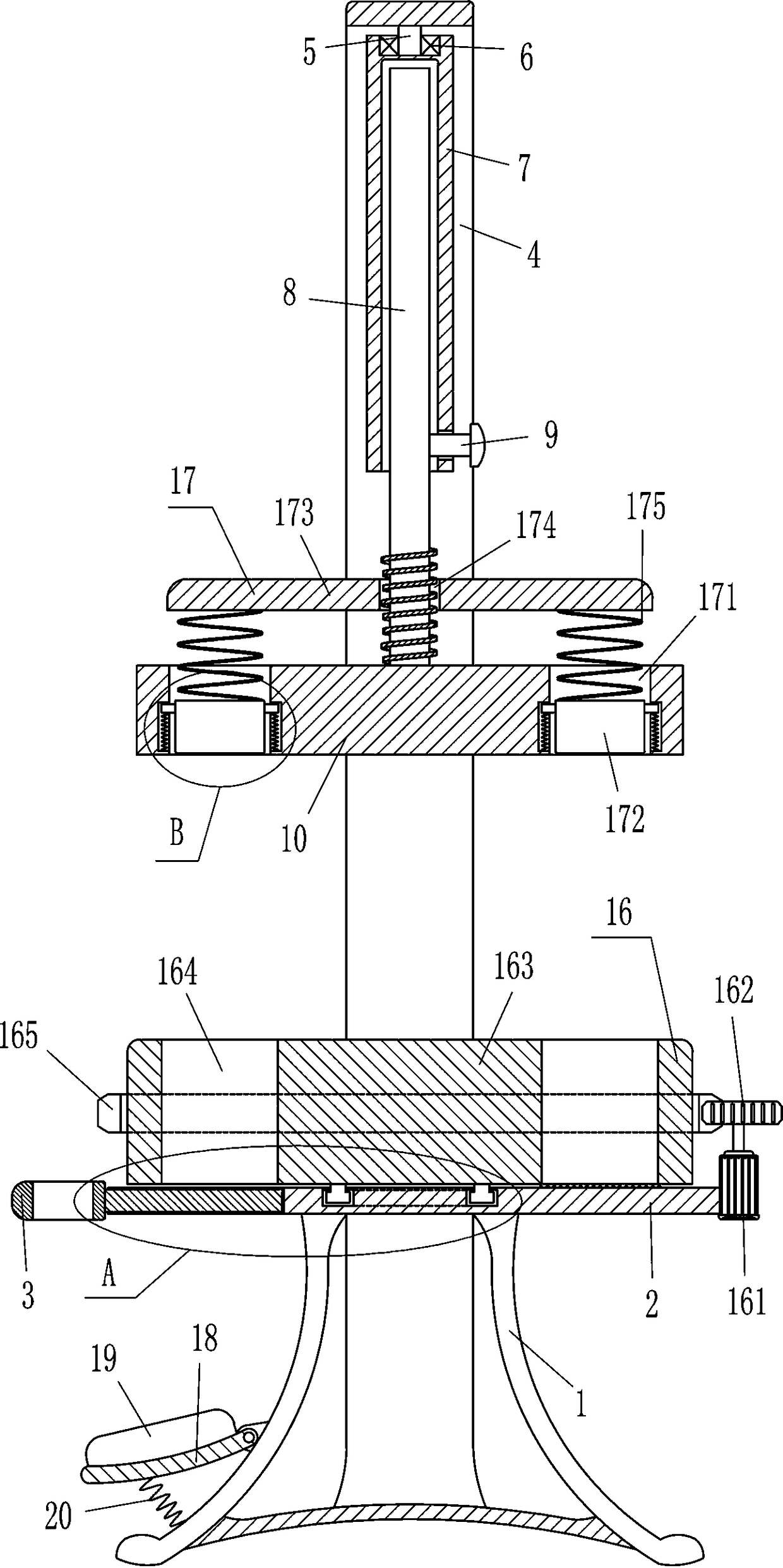

[0022] A cylindrical metal raw material burr grinding machine, such as Figure 1-4 As shown, it includes a support frame 1, a circular plate 2, a handle 3, a 7-shaped plate 4, a rotating shaft 5, a bearing seat 6, a sleeve 7, a movable rod 8, a fastening bolt 9, a circular block 10, and a block 12 , ring slider 14, grinding block 15 and rotating device 16, the top of the support frame 1 is fixedly connected with a circular plate 2, and there is an annular chute 13 that plays a guiding role in the middle of the top of the circular chute 13, and the sliding type in the annular chute 13 Two ring sliders 14 are provided, and the ring sliders 14 are slidably matched with the ring chute 13. A rotating device 16 for placing cylindrical metal raw materials is provided between the top of the two ring sliders 14 and the circular plate 2. There are multiple grinding blocks 15 that can grind the burrs of cylindrical metal raw materials, and the grinding blocks 15 are evenly spaced and ins...

Embodiment 2

[0024] A cylindrical metal raw material burr grinding machine, such as Figure 1-4As shown, it includes a support frame 1, a circular plate 2, a handle 3, a 7-shaped plate 4, a rotating shaft 5, a bearing seat 6, a sleeve 7, a movable rod 8, a fastening bolt 9, a circular block 10, and a block 12 , ring slider 14, grinding block 15 and rotating device 16, the top of the support frame 1 is fixedly connected with a circular plate 2, and there is an annular chute 13 that plays a guiding role in the middle of the top of the circular chute 13, and the sliding type in the annular chute 13 Two ring sliders 14 are provided, and the ring sliders 14 are slidably matched with the ring chute 13. A rotating device 16 for placing cylindrical metal raw materials is provided between the top of the two ring sliders 14 and the circular plate 2. There are multiple grinding blocks 15 that can grind the burrs of cylindrical metal raw materials, and the grinding blocks 15 are evenly spaced and inst...

Embodiment 3

[0027] A cylindrical metal raw material burr grinding machine, such as Figure 1-4 As shown, it includes a support frame 1, a circular plate 2, a handle 3, a 7-shaped plate 4, a rotating shaft 5, a bearing seat 6, a sleeve 7, a movable rod 8, a fastening bolt 9, a circular block 10, and a block 12 , ring slider 14, grinding block 15 and rotating device 16, the top of the support frame 1 is fixedly connected with a circular plate 2, and there is an annular chute 13 that plays a guiding role in the middle of the top of the circular chute 13, and the sliding type in the annular chute 13 Two ring sliders 14 are provided, and the ring sliders 14 are slidably matched with the ring chute 13. A rotating device 16 for placing cylindrical metal raw materials is provided between the top of the two ring sliders 14 and the circular plate 2. There are multiple grinding blocks 15 that can grind the burrs of cylindrical metal raw materials, and the grinding blocks 15 are evenly spaced and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com