Vibration unloading device for bulk powder in container soft bag

A technology of unloading device and container, which is applied in loading/unloading, packaging, liquid handling, etc. It can solve the problems of difficult unloading and unloading, slow packaging and packing speed, high packaging materials and labor costs, and achieve low system investment , cost saving, stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

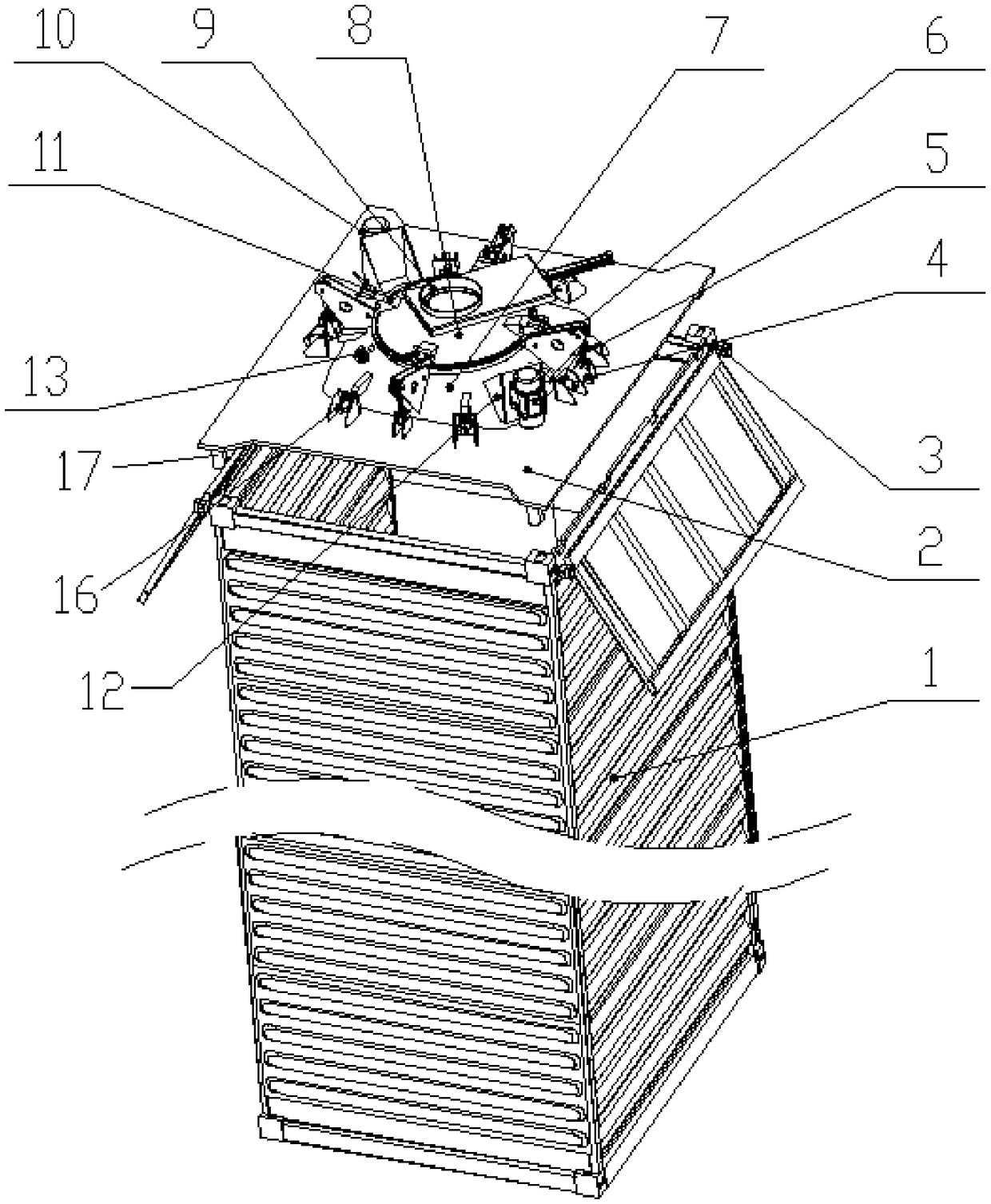

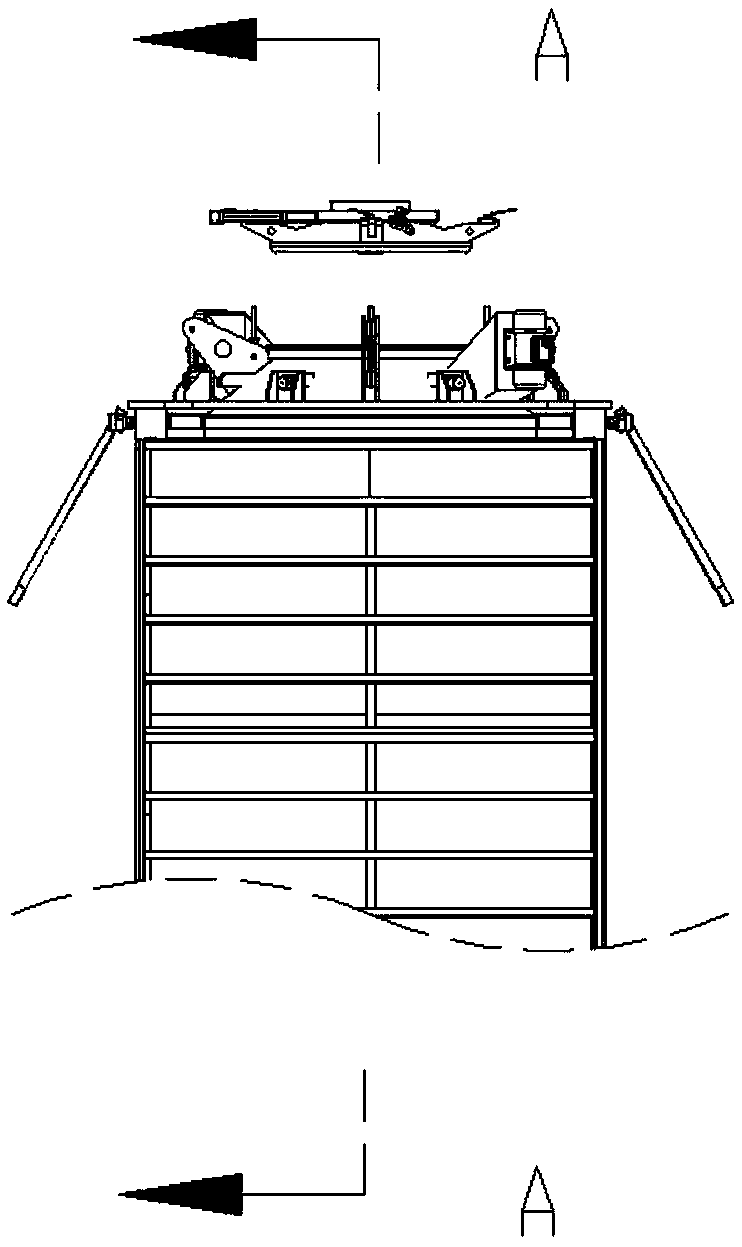

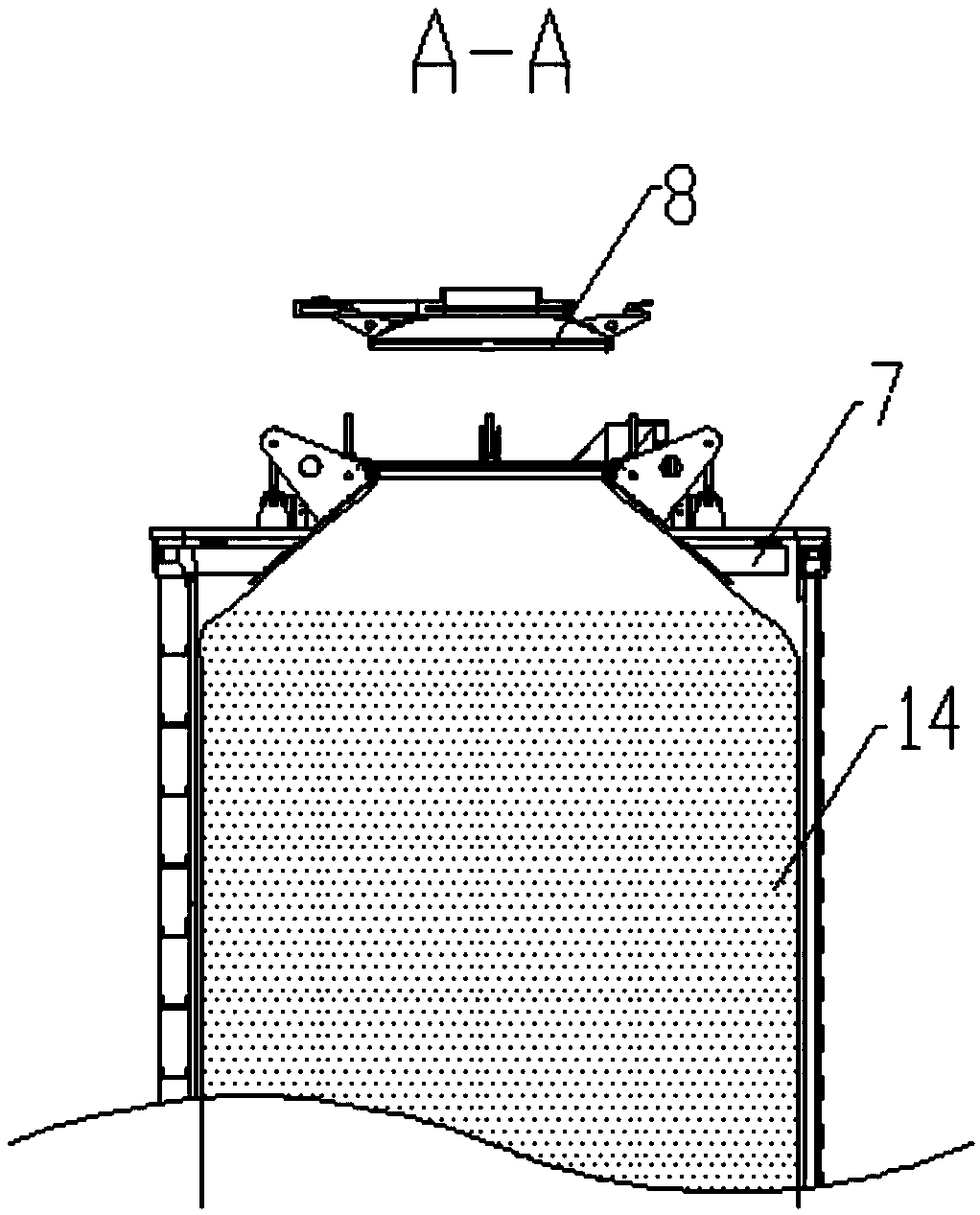

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0023] Such as Figure 1-5 Shown: the matching bag used in the present invention is an ordinary degradable film bag, which only plays the role of isolating the flour from the inner surface of the container. When unloading is required, only the container mouth needs to be opened upwards. After installing the device, untie the bag mouth After being sleeved on the entrainment port of the device and locked, the material can be turned over and unloaded. The discharge port is large, and the material is discharged by free fall and vibration, with high speed, no residue, and low power consumption. It truly embodies the low cost and fast operation of container powder transportation, and can promote the rapid development of container powder business. This is especially suitable for the problem that my country’s vast territory cannot use powder bulk transportation in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com