Rice collecting and releasing device for rice processing with dust removal function

A rice processing and rice technology, applied in the directions of loading/unloading, transportation and packaging, separating solids from solids by air flow, etc., can solve the problems of long collection time, high labor intensity, inconvenient collection, etc., and achieve flexible use. Convenience and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

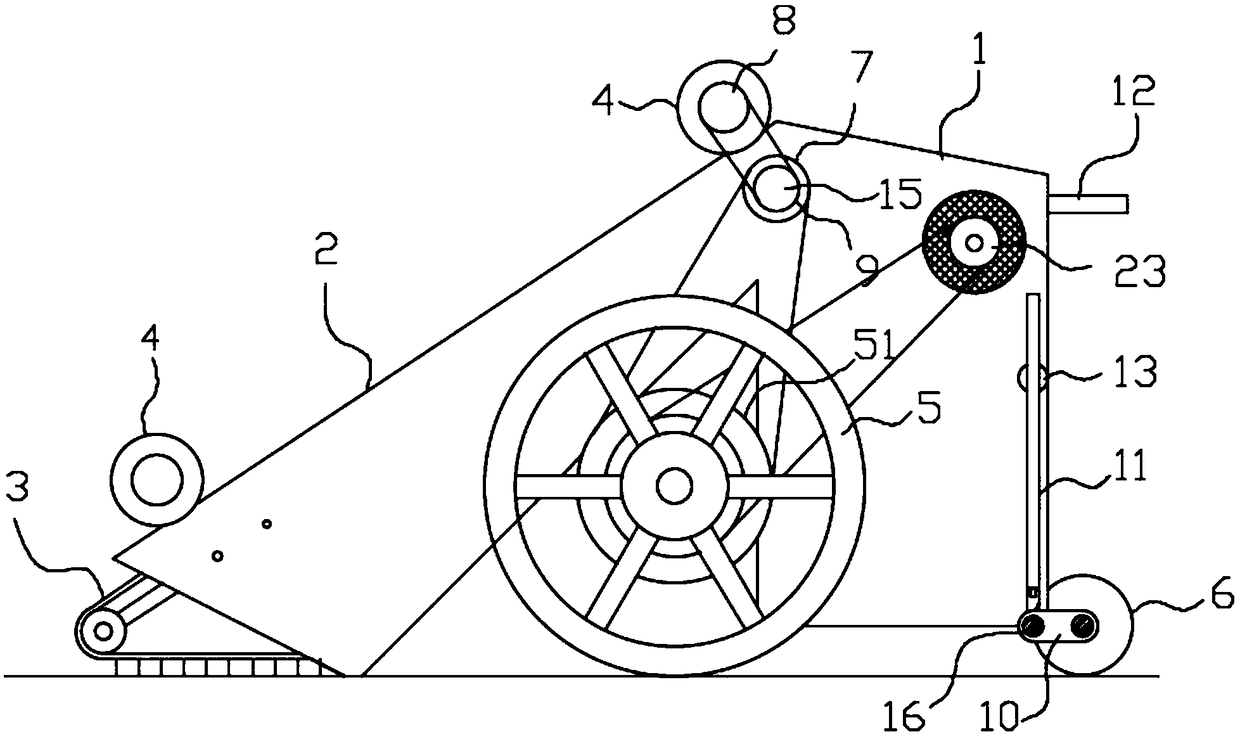

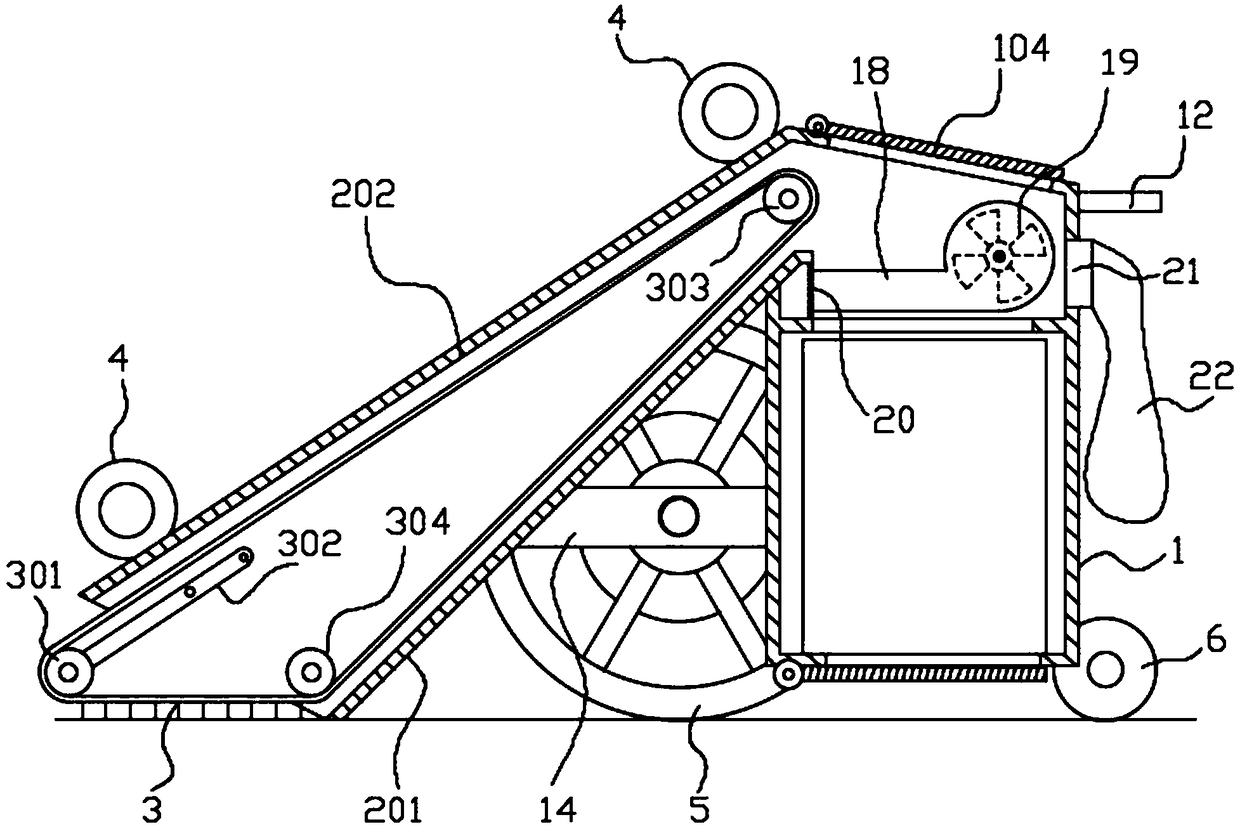

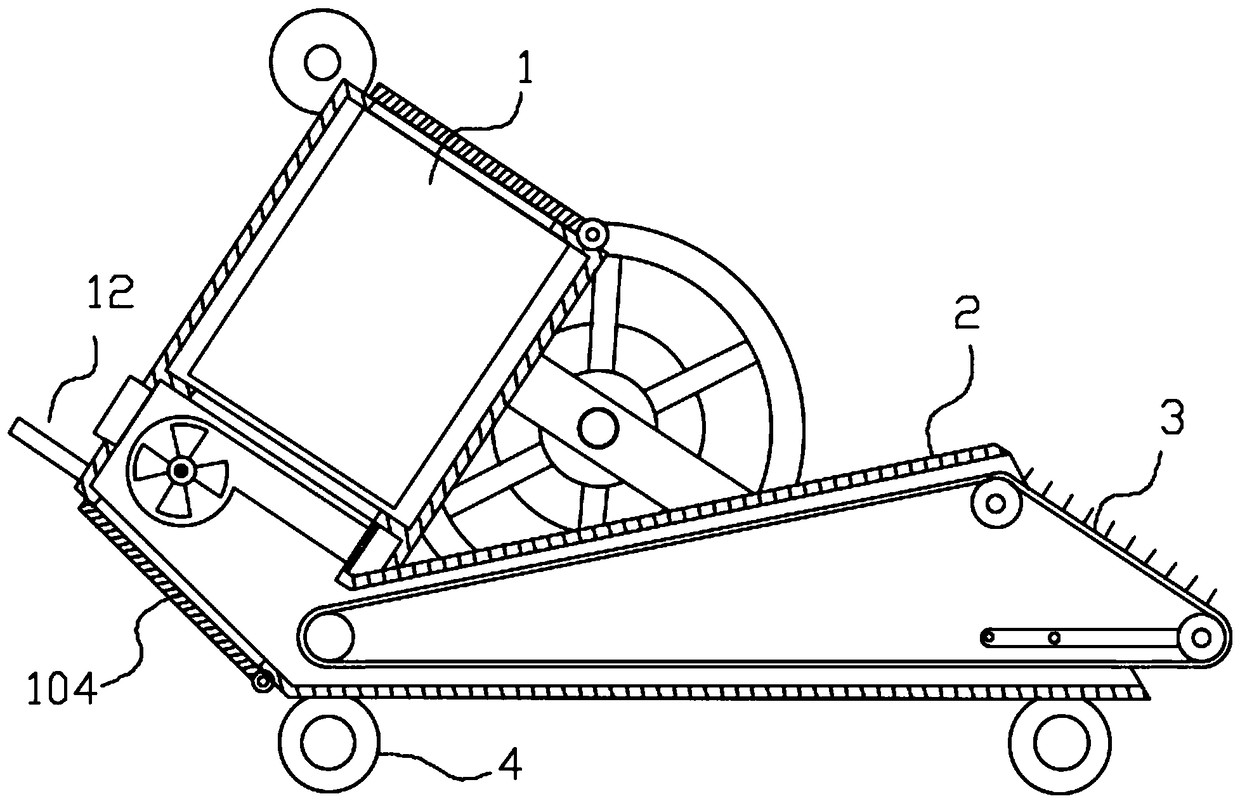

[0025] Such as Figure 1-Figure 6 Shown, the concrete structure of the present invention is:

[0026] A device for storing and storing rice for rice processing with dust removal function, which includes a box body 1 and a sleeve 2; the sleeve 2 communicates with the upper end of the box body 1, and the lower end is open and carried on the ground; the sleeve 2. The inner wall of the back plate constitutes the discharge slide 202, and the inner wall of the bottom plate constitutes the feed slide 201; the sleeve 2 is provided with a conveyor belt 3; the conveyor belt 3 is distributed in a triangle, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com