Mounted type full automatic core drilling machine

A fully automatic, coring machine technology, used in the extraction of undisturbed core devices, earthwork drilling and other directions, can solve the problems of unsafe, small drilling depth, small aperture, etc., to ensure verticality and smoothness, and large hole diameter. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

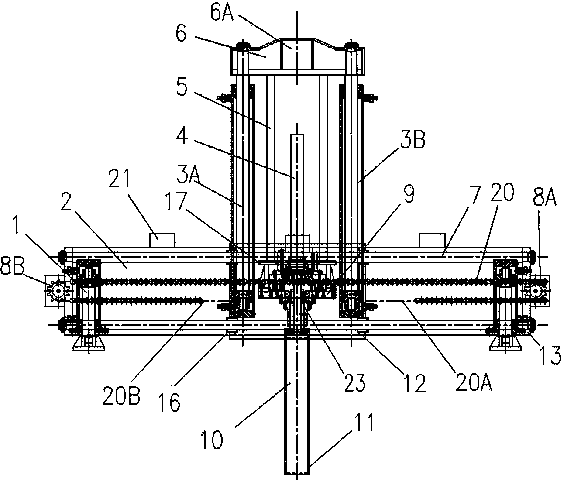

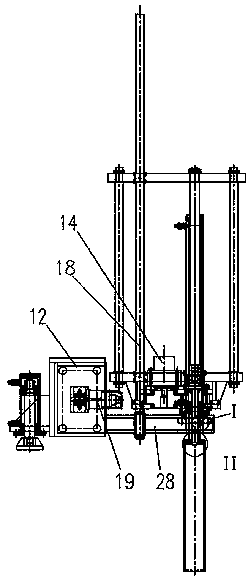

[0020] like Figure 1 to Figure 4 As shown, a mountable fully automatic coring machine includes a rail frame 2 on which a mounting seat 21 and a hydraulic support leg 1 are arranged. The coring machine can be installed on the excavator or the loader through the mounting base 21, and the horizontal position of the coring machine can be adjusted through the hydraulic support leg 1.

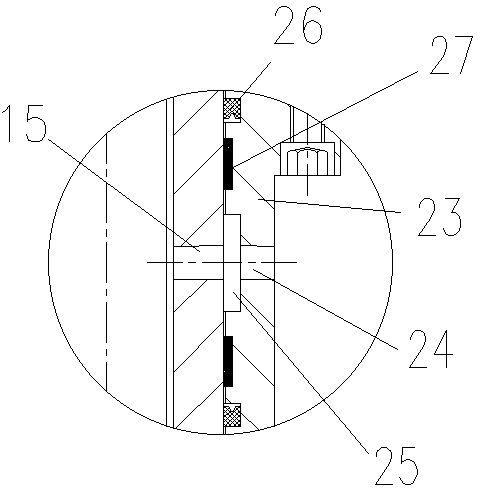

[0021] Rail frame 2 is provided with slideway 7, is equipped with copper sleeve 16 on slideway 7, and copper sleeve 16 is fixed with slide plate 12.

[0022] A first oil cylinder 3A and a second oil cylinder 3B are fixed at intervals on the slide plate 12 . The piston rods of the first oil cylinder 3A and the second oil cylinder 3B are all fixedly connected with the upper plate 6 , four pull rods 5 parallel to the piston rods are fixed at intervals on the upper plate 6 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com