Absorption heating and refrigerating all-in-one machine taking high-temperature gas as heat source

A high-temperature gas and absorption heat pump technology, applied in the field of energy technology applications, can solve the problems that gaseous waste heat resources cannot be fully utilized, latent heat cannot be fully utilized, etc., and achieve the effect of improving energy utilization efficiency and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

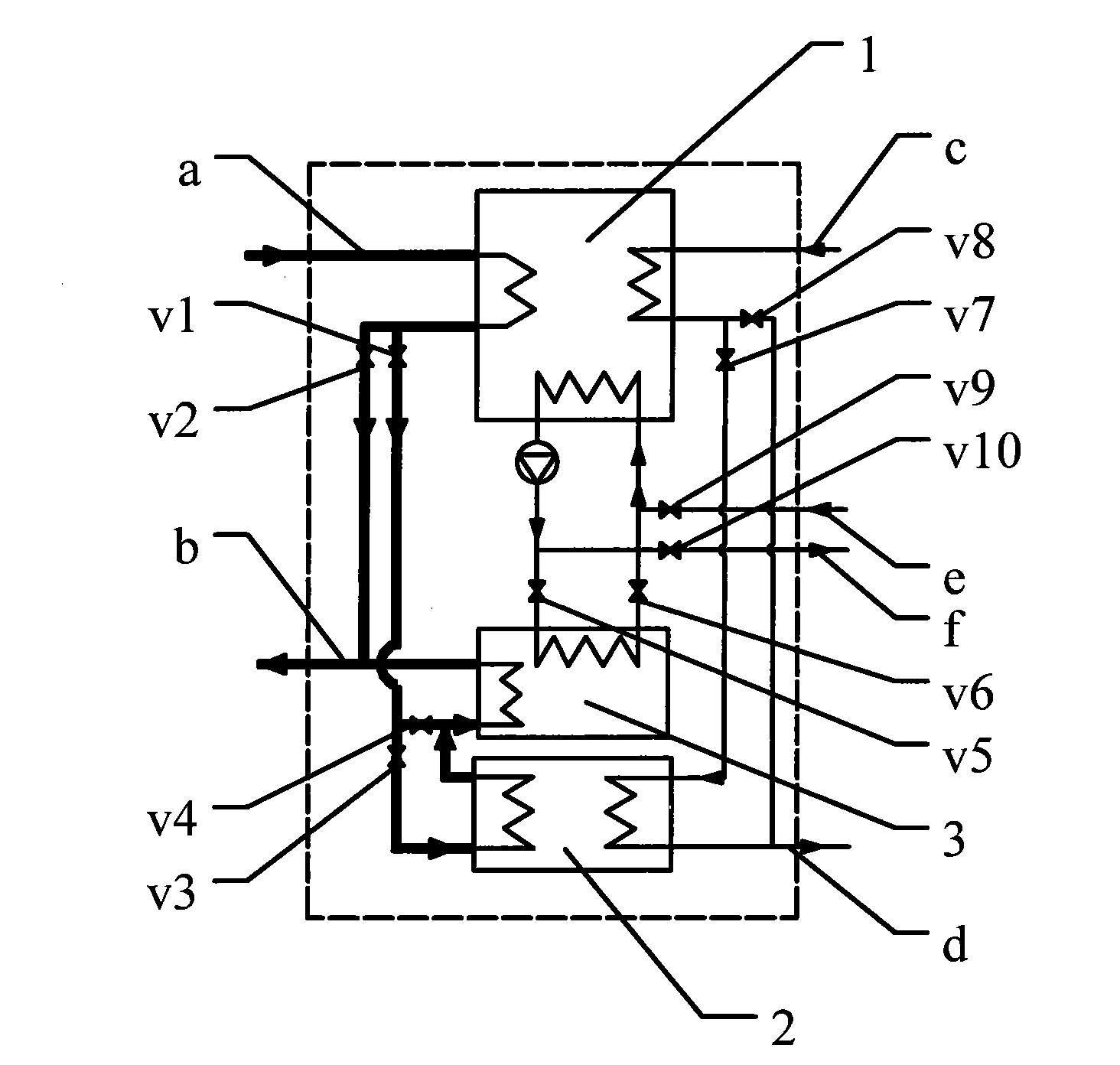

Embodiment 1

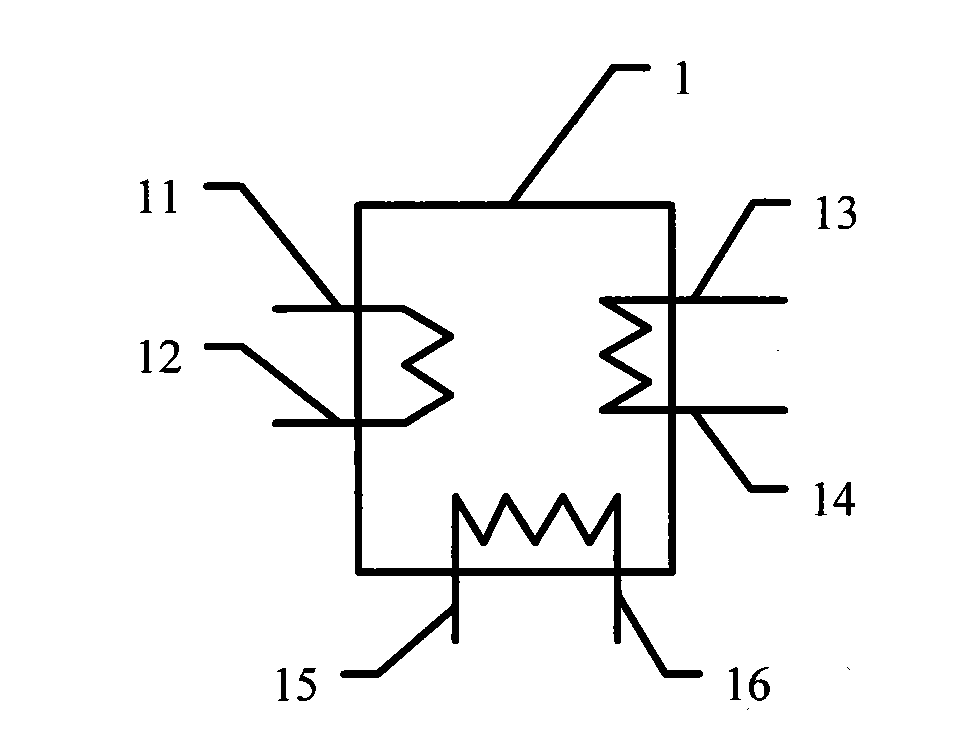

[0033] Figure 5 It is a schematic flow chart of the first connection mode in the heating condition of the present invention. The first valve v1, the third valve v3, the fifth valve v5, the sixth valve v6, the seventh valve v7 open, the second valve v2, the fourth valve v4, the eighth valve v8, the ninth valve v9, the tenth valve v10 closure. The high-temperature gas is flue gas at 530°C. The high-temperature flue gas first enters the absorption heat pump unit 1 from the high-temperature gas pipeline a from the generator inlet 11 as a driving heat source, and the high-temperature flue gas is heated and concentrated in the generator of the absorption heat pump unit 1. LiBr The solution is discharged from the generator outlet 12 of the absorption heat pump 1 when the temperature drops to 210°C, and the flue gas at 210°C enters the high-temperature gas-water heat exchanger 2 from the gas side inlet 22 of the high-temperature heat exchanger as a heating source, and cools down to ...

Embodiment 2

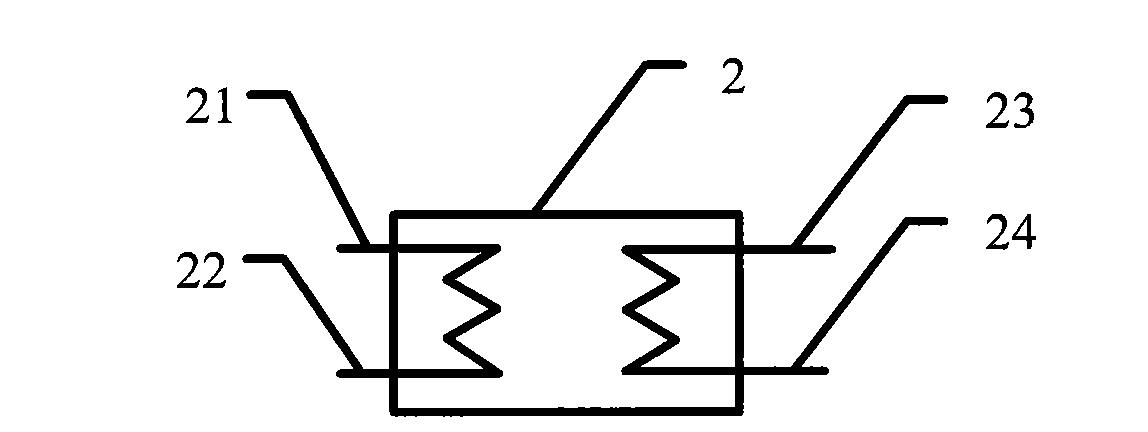

[0035] Figure 6 It is a schematic flow chart of the second connection mode in the heating condition of the present invention. The first valve v1, the fourth valve v4, the fifth valve v5, the sixth valve v6, the eighth valve v8 open, the second valve v2, the third valve v3, the seventh valve v7, the ninth valve v9, the tenth valve v10 closure. The high-temperature gas is flue gas at 530°C. The high-temperature flue gas first enters the absorption heat pump unit 1 from the high-temperature gas pipeline a from the generator inlet 11 as a driving heat source, and the high-temperature flue gas is heated and concentrated in the generator of the absorption heat pump unit 1. LiBr The solution is discharged from the generator outlet 12 of the absorption heat pump 1 when the temperature drops to 130°C, and the flue gas at 130°C enters the low-temperature gas-water heat exchanger 3 through the gas side inlet 32 of the low-temperature heat exchanger, and is discharged from the The ex...

Embodiment 3

[0037] Figure 7 It is a schematic flow chart of the connection mode of refrigeration working conditions in the present invention. The second valve v2, the eighth valve v8, the ninth valve v9, and the tenth valve v10 are open, the first valve v1, the third valve v3, the fourth valve v4, the fifth valve v5, the sixth valve v6, and the seventh valve v7 closure. The high-temperature gas is flue gas at 530°C. The high-temperature flue gas first enters the absorption heat pump unit 1 from the high-temperature gas pipeline a from the generator inlet 11 as a driving heat source, and the high-temperature flue gas is heated and concentrated in the generator of the absorption heat pump unit 1. LiBr The solution is discharged from the generator outlet 12 of the absorption heat pump 1 through the exhaust pipe b when the temperature is lowered to 130°C; on the chilled water side, the chilled water return water at 12°C passes through the chilled water return pipe e through the evaporator inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com