Spiral Roller Mowing and Snow Sweeping All-in-One Machine

A roll-cutting, all-in-one machine technology, which is applied to cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of labor-intensive weeding efficiency, low integration, and high power consumption, and achieve labor-saving and efficient mowing. Strong applicability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

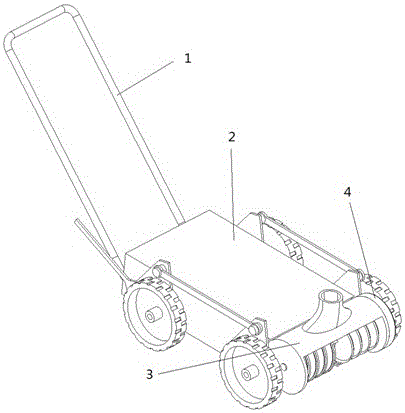

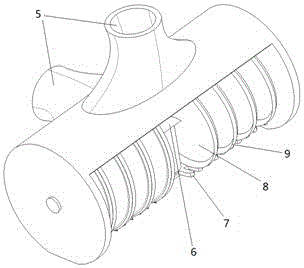

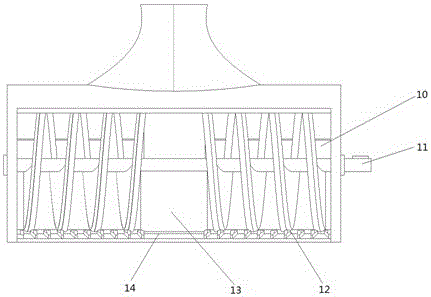

[0029] Such as figure 1 with Image 6 As shown, the spiral rolling cutting grass mowing and snow sweeping machine includes a push rod 1, a traveling frame 2 hinged to the lower end of the push rod, and rollers installed on both sides of the traveling frame, which are fixed to the front end of the traveling frame by fixing bolts. The dual-purpose roller actuator, and the driving motor 4 installed on any side of the dual-purpose roller actuator and connected with the key of the dual-purpose roller actuator, wherein the traveling frame includes a parallelogram height-adjusting wheel mechanism arranged at its two ends, through This mechanism can adjust the height of the walking frame, and then adjust the height of the walking frame to achieve the purpose of mowing or snow removal. The parallelogram height-adjusting wheel mechanism includes a height-adjusting handle 16, which is connected with the height-adjusting handle and installed on the walking vehicle. The roller shaft 17 on...

Embodiment 2

[0034] Such as Figure 7 As shown, the spiral rolling cutting grass mowing and snow sweeping all-in-one machine is different from the embodiment 1 in that the double spiral disks of the spiral disk hob are directly docked in a deflection of 180°, and a pair of parabolic disks are arranged on the two docking sections. plate 19. When this structure is adopted, the parabolic plate does not need to be provided with a parabolic plate edge on the outer edge of the parabolic plate.

Embodiment 3

[0036] The spiral hob cutter is different from Embodiment 1 in that the spiral hob has a single helical structure, and a parabolic plate is provided at one or both ends, and a parabolic plate edge is provided on the edge of the parabolic plate. At the position corresponding to the end of the fixed knife plate, there is a cutting edge at the end of the fixed knife plate. When this structure is adopted, the parabolic mouth is also set at the end correspondingly, and the position corresponds to the position of the parabolic plate. Snow or Grass is discharged from the end of the drum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com