Bidirectional step-by-step telescopic electric cylinder and tyre crane

A technology of electric cylinders and motors, which is applied to cranes, electric components, electrical components, etc., to achieve the effects of accurate position, improved service life, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

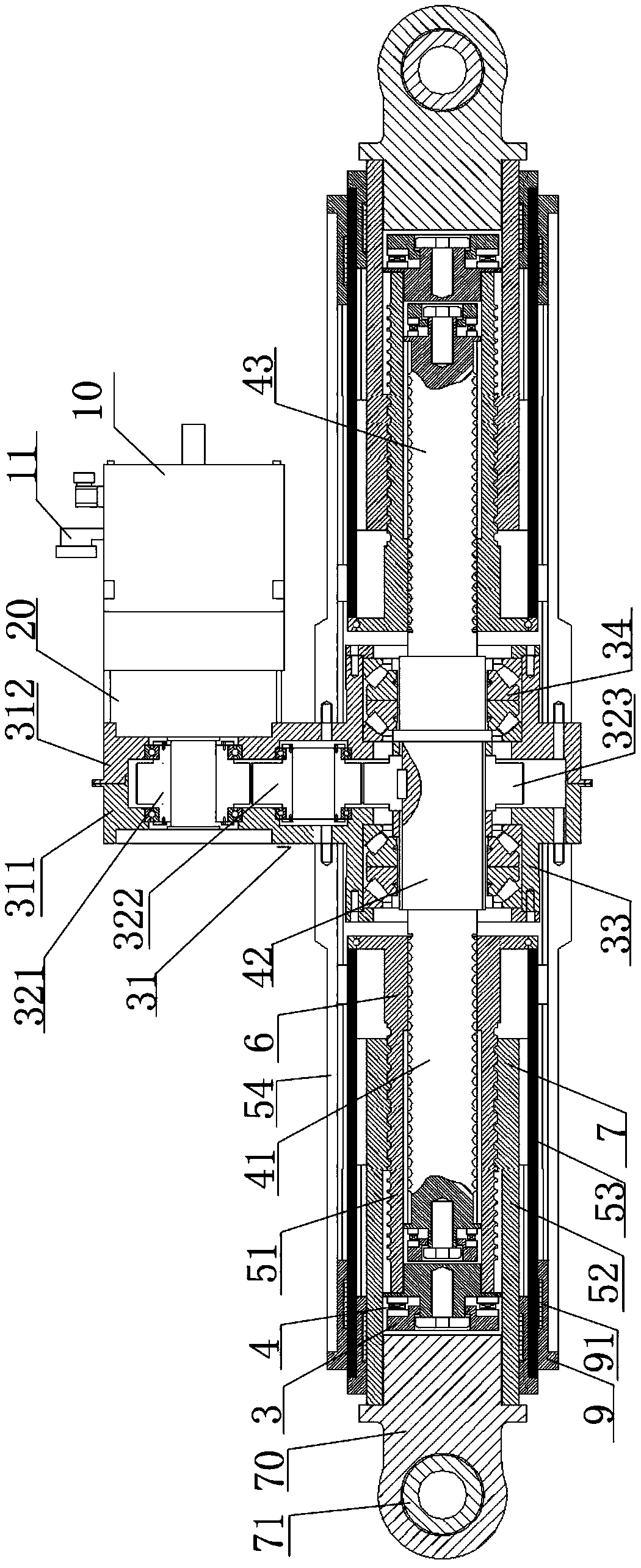

[0062] A two-way step-by-step telescopic electric cylinder, such as figure 1 As shown, the telescopic electric cylinder includes: a motor 10, a reducer 20, a gear box assembly, a primary screw, a left telescopic cylinder assembly, a right telescopic cylinder assembly, and a connecting fish ear 70 or a connecting flange.

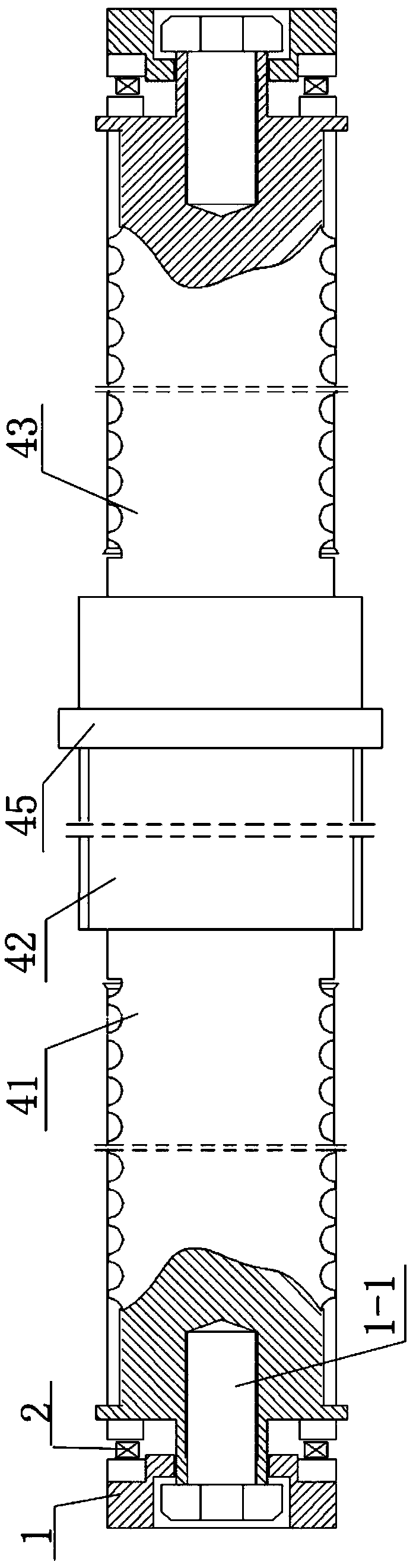

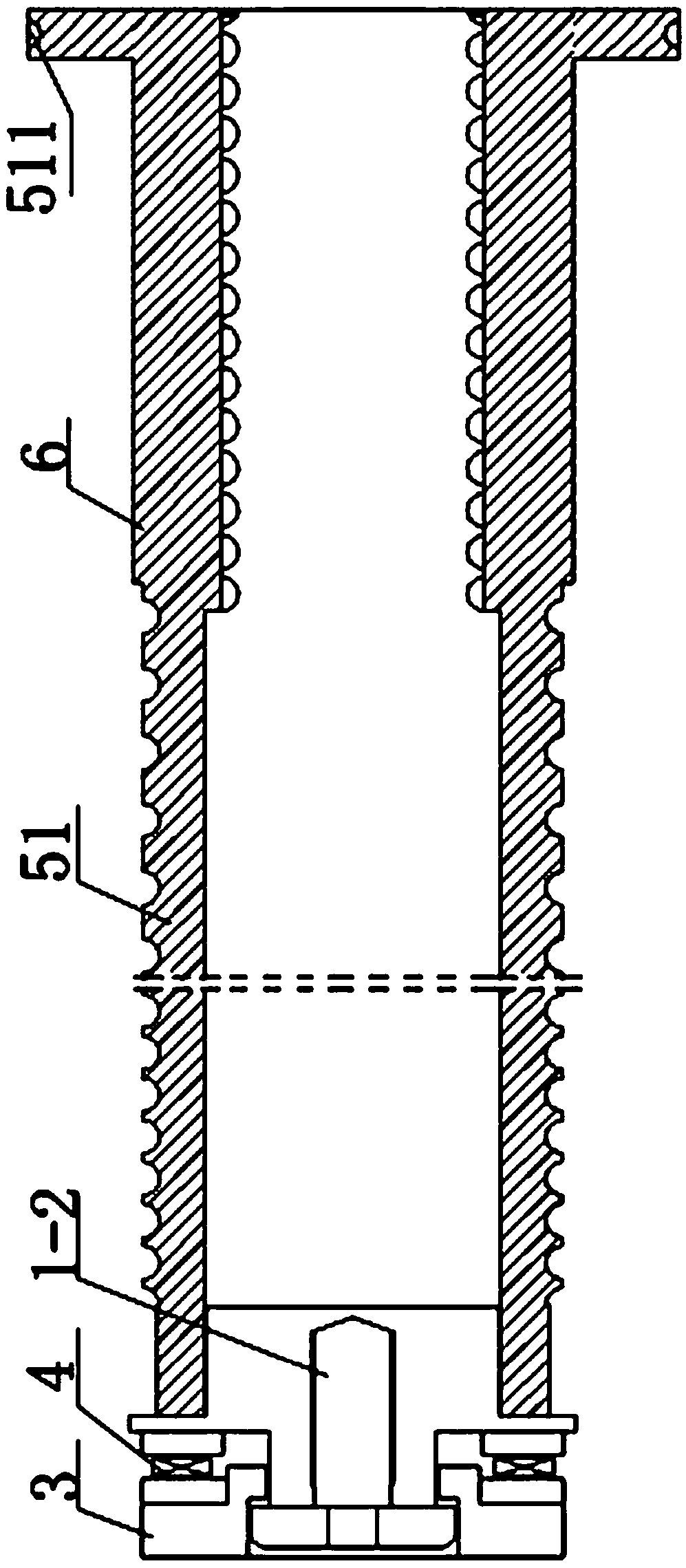

[0063] The primary screw is divided into: a left-handed end 41 of the primary screw, an optical axis 42 and a right-handed end 43 of the primary screw. The screw threads of the left-handed section 41 of the first-stage lead screw and the right-handed section 43 of the first-stage lead screw are in opposite directions, so that the left and right ends can extend or shrink simultaneously. The ends of the left-handed end 41 of the first-level leading screw and the right-handed end 43 of the first-level leading screw are all fixedly arranged: the first rotary gland 1 (refer to figure 2 ), and between the first rotary gland 1 and the end faces of the left-handed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com