Preparation method of graphene intercalation compound

A graphite intercalation and compound technology, which is applied in the field of preparation of graphene intercalation compounds, can solve problems that are difficult to apply in the field of microelectronic device manufacturing, and achieve the effect of low equipment requirements and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

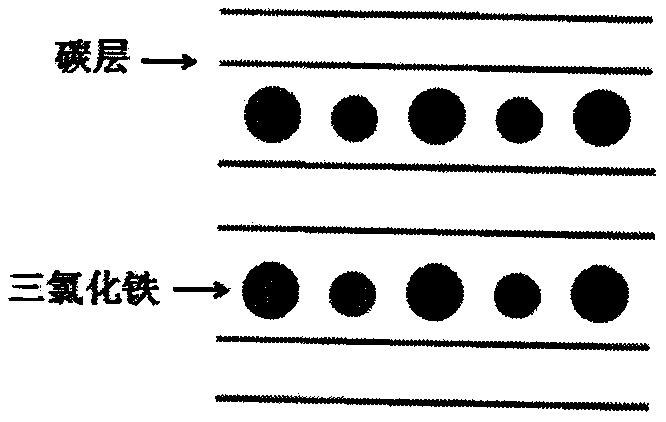

[0023] (1) Mix 300mg of anhydrous ferric chloride and 60mg of expanded graphite evenly, vacuumize, seal in a 50mL glass bottle, and heat at 400°C for 4h to prepare a pure second-order graphite intercalation compound.

[0024] (2) Dissolve the graphite intercalation compound in dilute hydrochloric acid solution, filter and dry with suction.

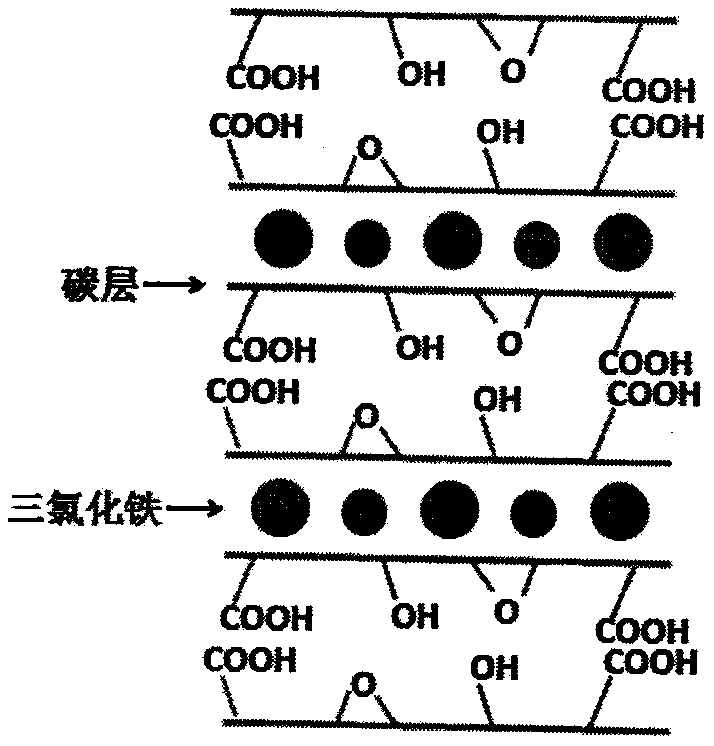

[0025] (3) The graphite intercalation compound was added into a mixed solution of 20 mL of concentrated sulfuric acid and 10 mL of concentrated nitric acid, and stirred in ice water (0° C.) for 0.5 hours.

[0026] (4) 360 mg of sodium chlorate was put into the solution, stirred at room temperature for 12 hours, and the product was centrifuged and washed.

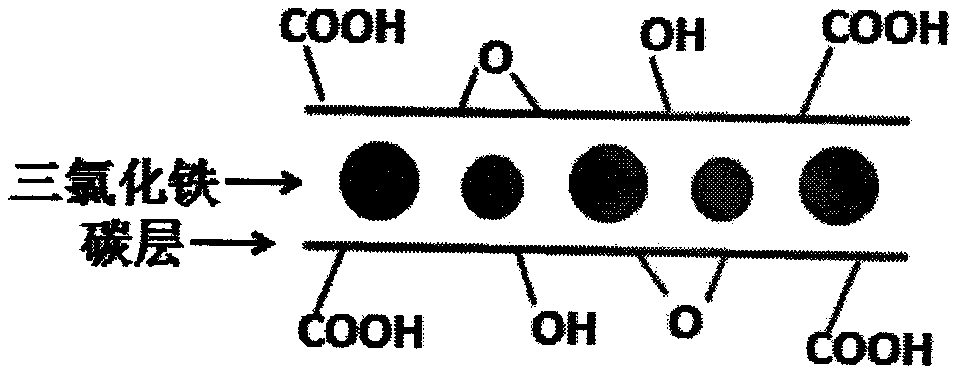

[0027] (5) The product was added into an aqueous solution, and ultrasonicated for 1 h to obtain a graphene intercalation compound.

Embodiment 2

[0029] (1) Mix 300mg of anhydrous ferric chloride and 60mg of expanded graphite evenly, vacuumize, seal in a 50mL glass bottle, and heat at 400°C for 6h to prepare a pure second-order graphite intercalation compound.

[0030] (2) Dissolve the graphite intercalation compound in dilute hydrochloric acid solution, filter and dry with suction.

[0031] (3) The graphite intercalation compound was added into a mixed solution of 20 mL of concentrated sulfuric acid and 10 mL of concentrated nitric acid, and stirred in ice water (0° C.) for 0.5 hours.

[0032] (4) 360 mg of sodium chlorate was put into the solution, stirred at room temperature for 12 hours, and the product was centrifuged and washed.

[0033] (5) The product was added into an aqueous solution, and ultrasonicated for 1 h to obtain a graphene intercalation compound.

Embodiment 3

[0035] (1) Mix 300mg of anhydrous ferric chloride and 60mg of expanded graphite evenly, vacuumize, seal in a 50mL glass bottle, and heat at 400°C for 4h to prepare a pure second-order graphite intercalation compound.

[0036] (2) Dissolve the graphite intercalation compound in dilute hydrochloric acid solution, filter and dry with suction.

[0037] (3) Add the graphite intercalation compound into 40 mL of concentrated sulfuric acid solution, and stir in ice water (0° C.) for 0.5 hour.

[0038] (4) Put 360 mg of potassium permanganate into the solution, stir at room temperature for 12 hours, and centrifuge the product.

[0039] (5) The product was added into an aqueous solution, and ultrasonicated for 1 h to obtain a graphene intercalation compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com