Thermal treatment furnace

A technology of heat treatment furnace and furnace body, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of poor mechanical stability of materials and restrict the development of aluminum alloy hot forming, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

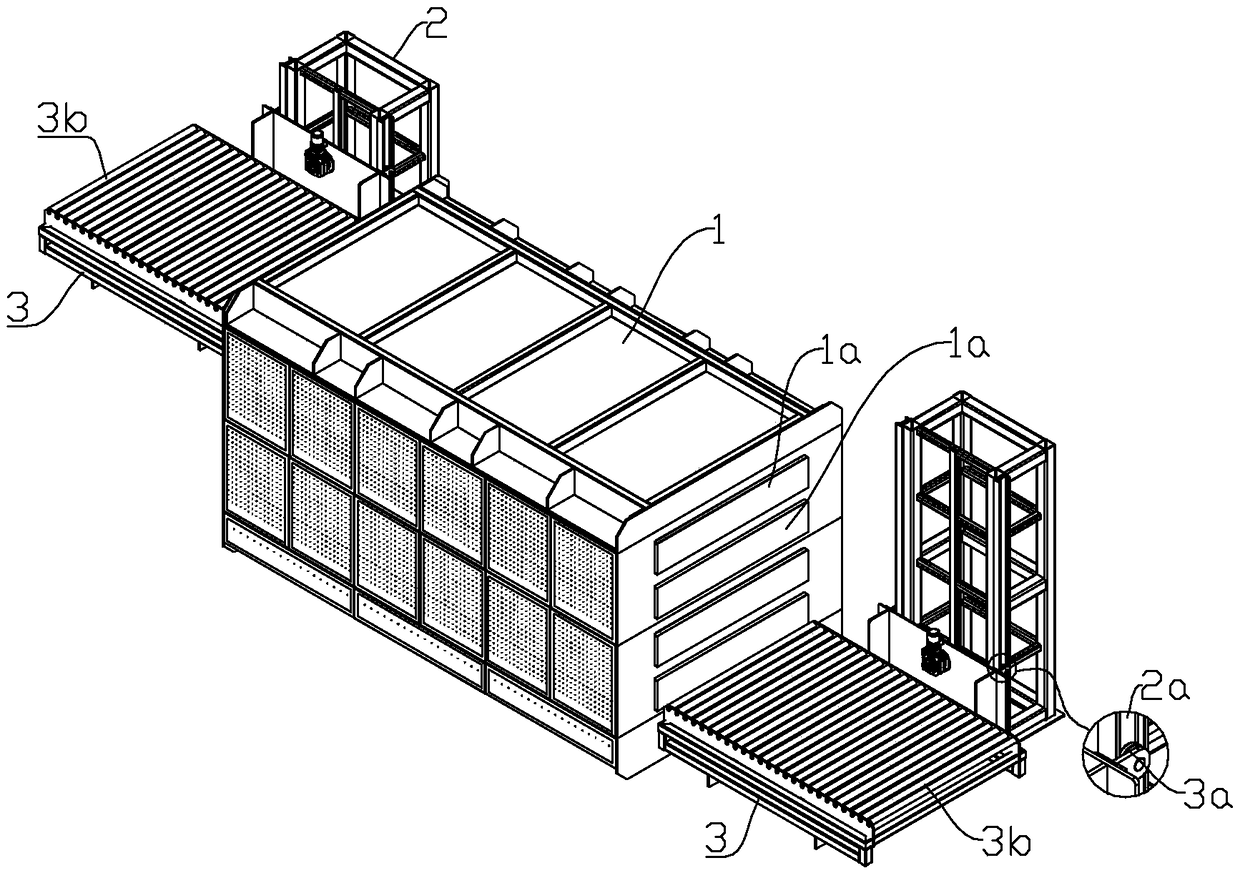

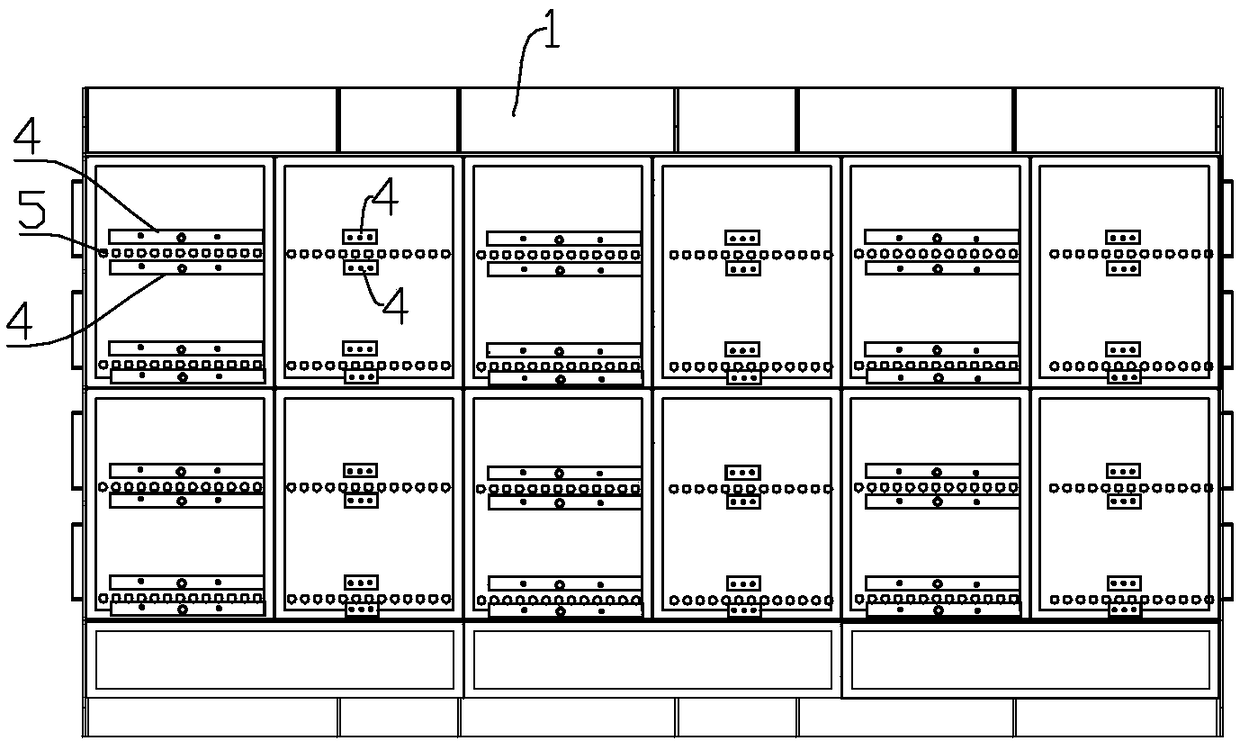

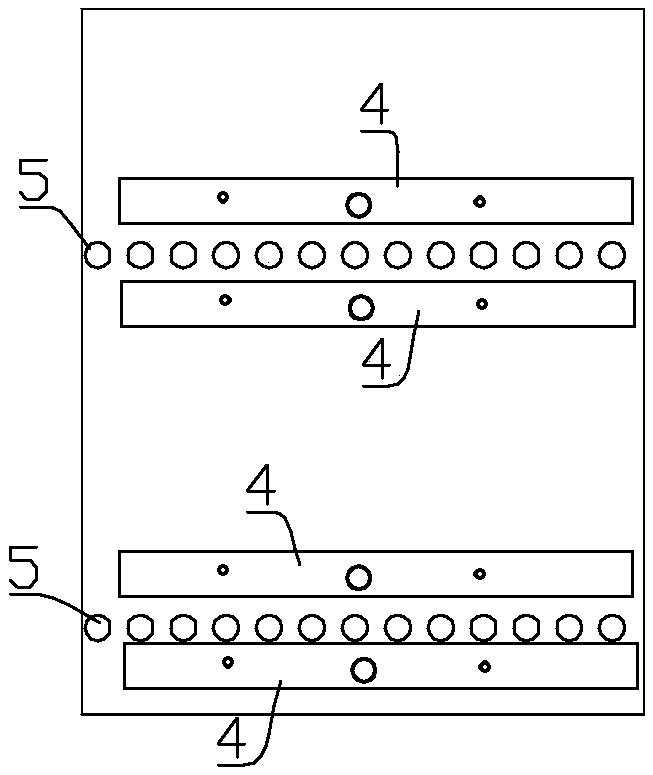

[0031] A heat treatment furnace, combined with figure 1 and figure 2 , the heat treatment furnace includes a furnace body 1, and a transfer roller 5 is arranged inside the furnace body 1; in order to improve heat treatment efficiency, the transfer roller 5 is distributed with multiple layers in the furnace body 1 in this embodiment; correspondingly, at the inlet and outlet ends of the furnace body 1 There are a plurality of furnace doors 1a corresponding to the number of layers of the conveying roller 5; the inlet and outlet ends of the furnace body 1 are respectively provided with a lifting platform 3 for feeding and discharging materials, and the side of the lifting platform 3 is slidingly connected to the lifting frame 2; The vertical chute 2a is arranged on both sides of the lifting frame 2, and the back of the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com