CCD regulating mechanism

A technology of adjusting mechanism and adjusting plate, which is applied in the directions of supporting machines, mechanical equipment, machines/brackets, etc., can solve the problems of low manual alignment efficiency and low alignment accuracy, and achieves strong practicability, guarantees high quality, improves The effect of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

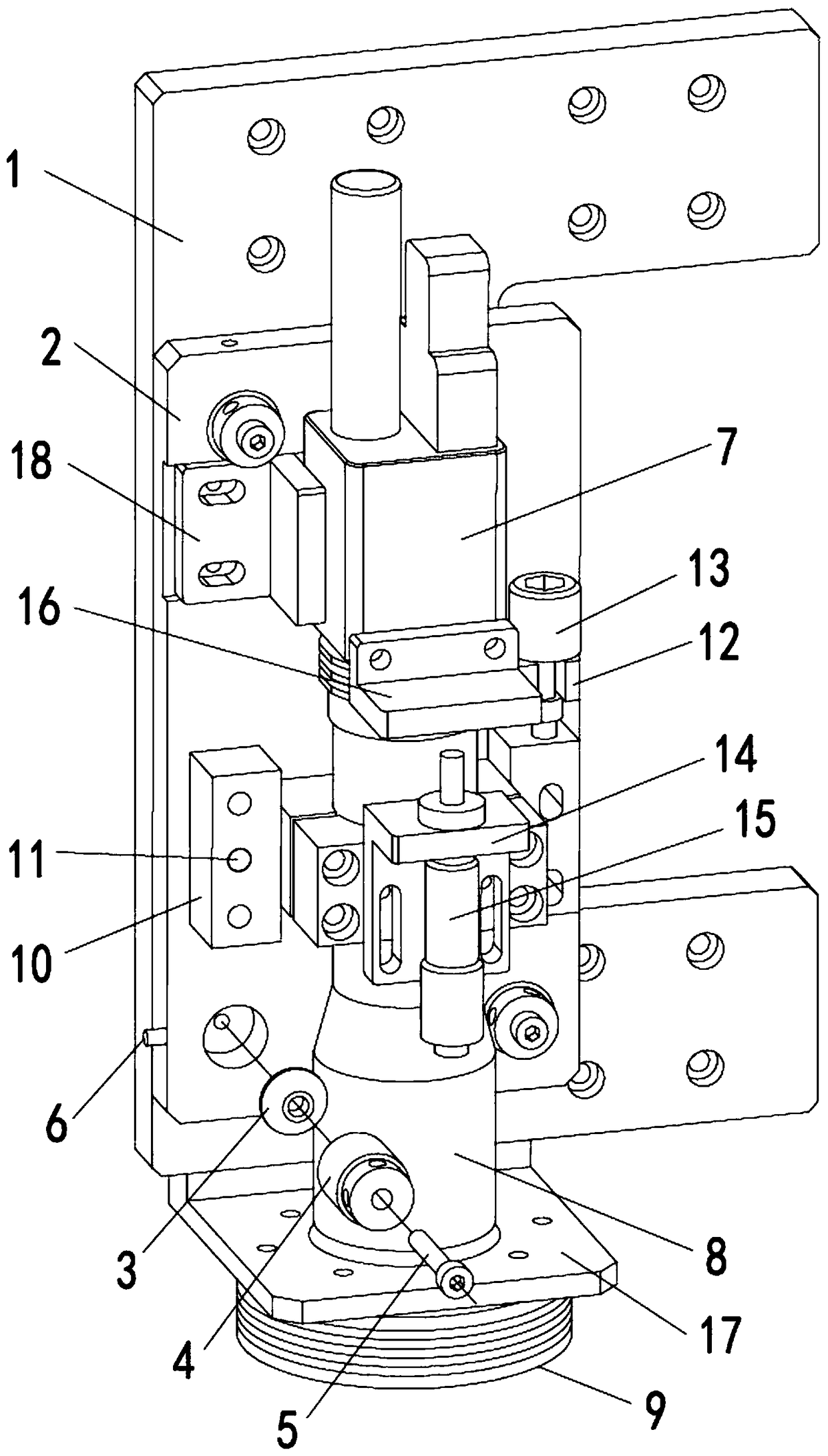

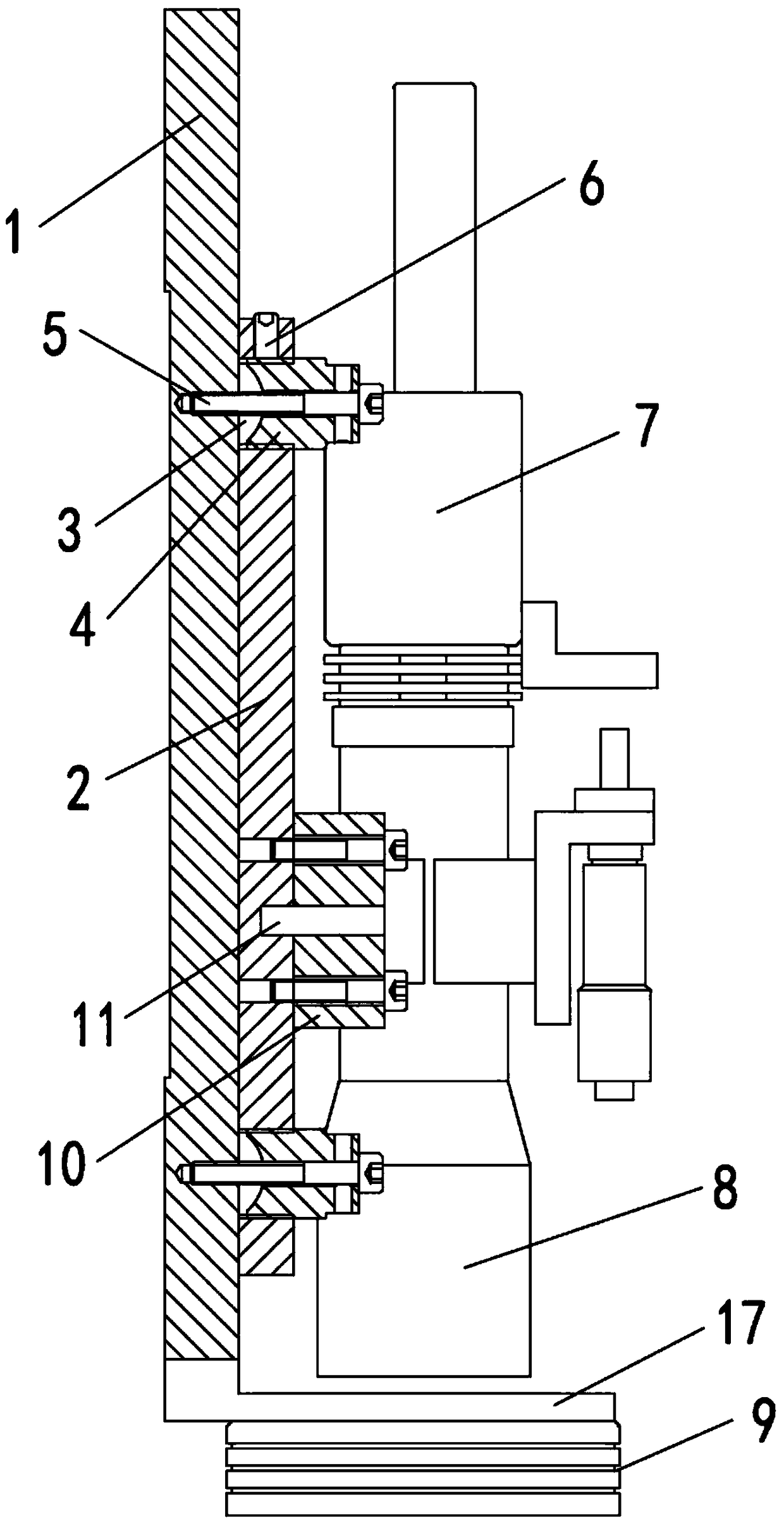

[0015] see Figure 1-Figure 2 As shown, the structure of the present invention includes a mounting substrate 1 , and a Y-direction adjustment component and a light source mounting plate 17 disposed on the mounting substrate 1 . The light source installation plate 17 is vertically fixed on the bottom of the installation substrate 1; the Y-direction adjustment assembly is connected to the outer surface of the installation substrate 1 through a plurality of installation modules, and the outer surface of the Y-direction adjustment assembly is installed with The X-direction adjustment assembly and the camera rough positioning backing plate 18; the X-direction adjustment assembly clamps and fixes the CCD camera assembly in the hoop plate in the middle, and a height is also provided on the outer surface of the CCD camera assembly and the X-direction adjustment assembly. An adjustment component; the camera coarse positioning support plate is vertically fixed on the side of the Y-direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com